Silicon single crystal, silicon wafer, and epitaxial wafer

a single crystal, silicon wafer technology, applied in the direction of crystal growth process, water-setting substance layered product, transportation and packaging, etc., can solve the problems of increasing leakage current, increasing leakage current, and shortening the life of the carrier,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

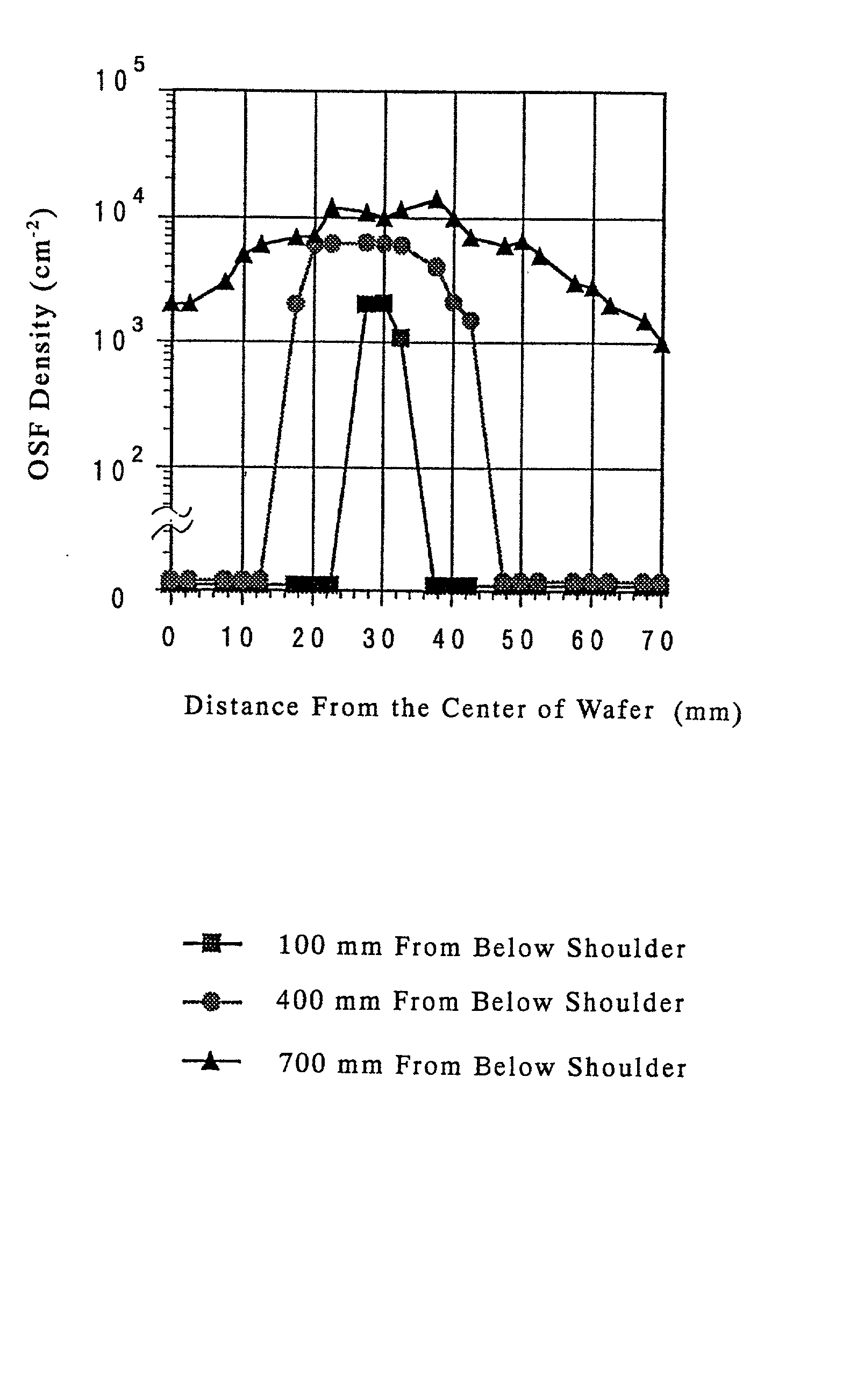

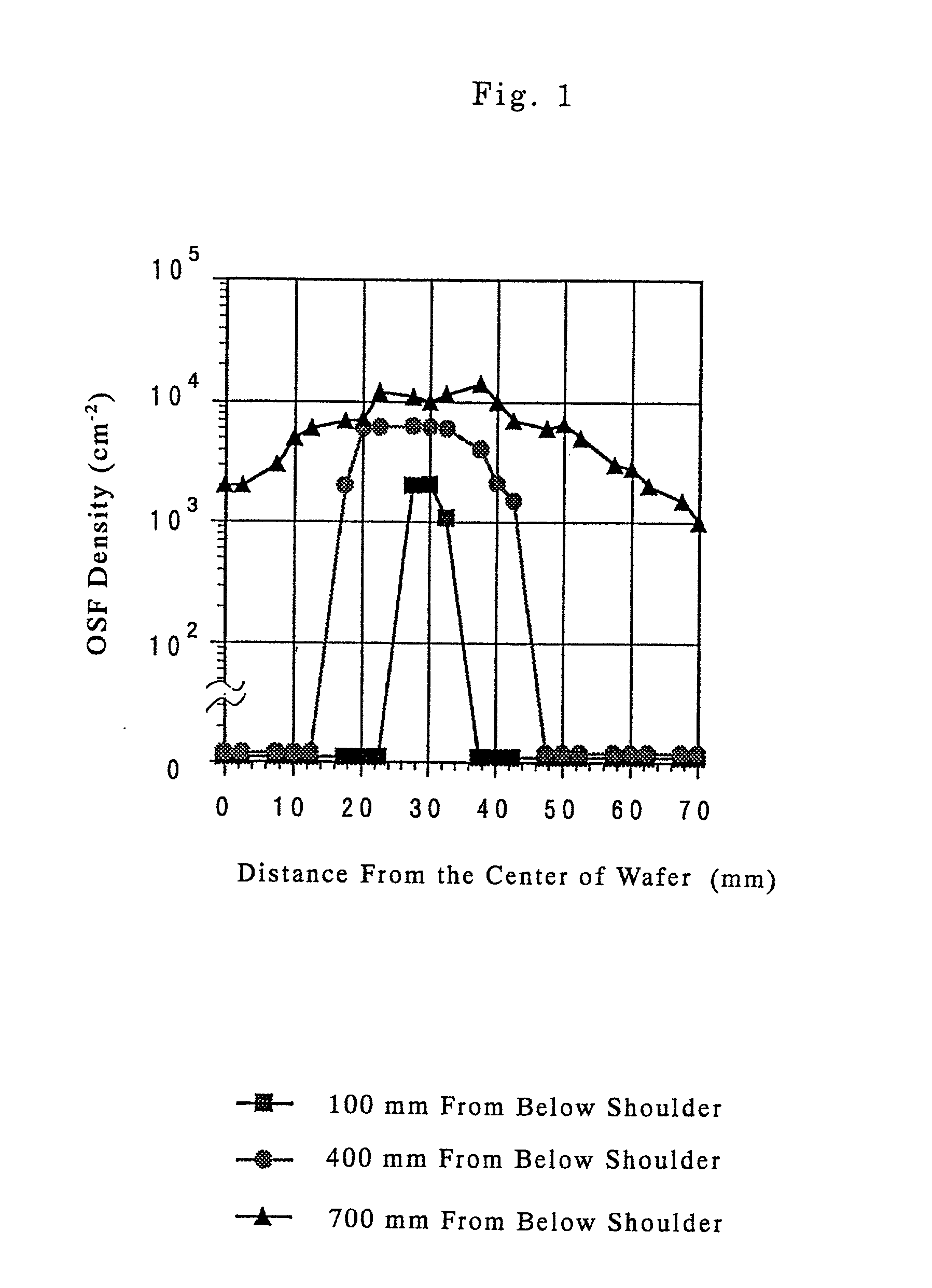

[0050] According to the Czochralski method, a single crystal was grown in the following manner; i.e., highly pure poly-crystalline silicon (50 kg) was melted in a quartz crucible along with boron serving as a dopant, and the single crystal having a diameter of 150 mm and a crystal orientation of was pulled at a pulling speed of 0.6 mm / min.

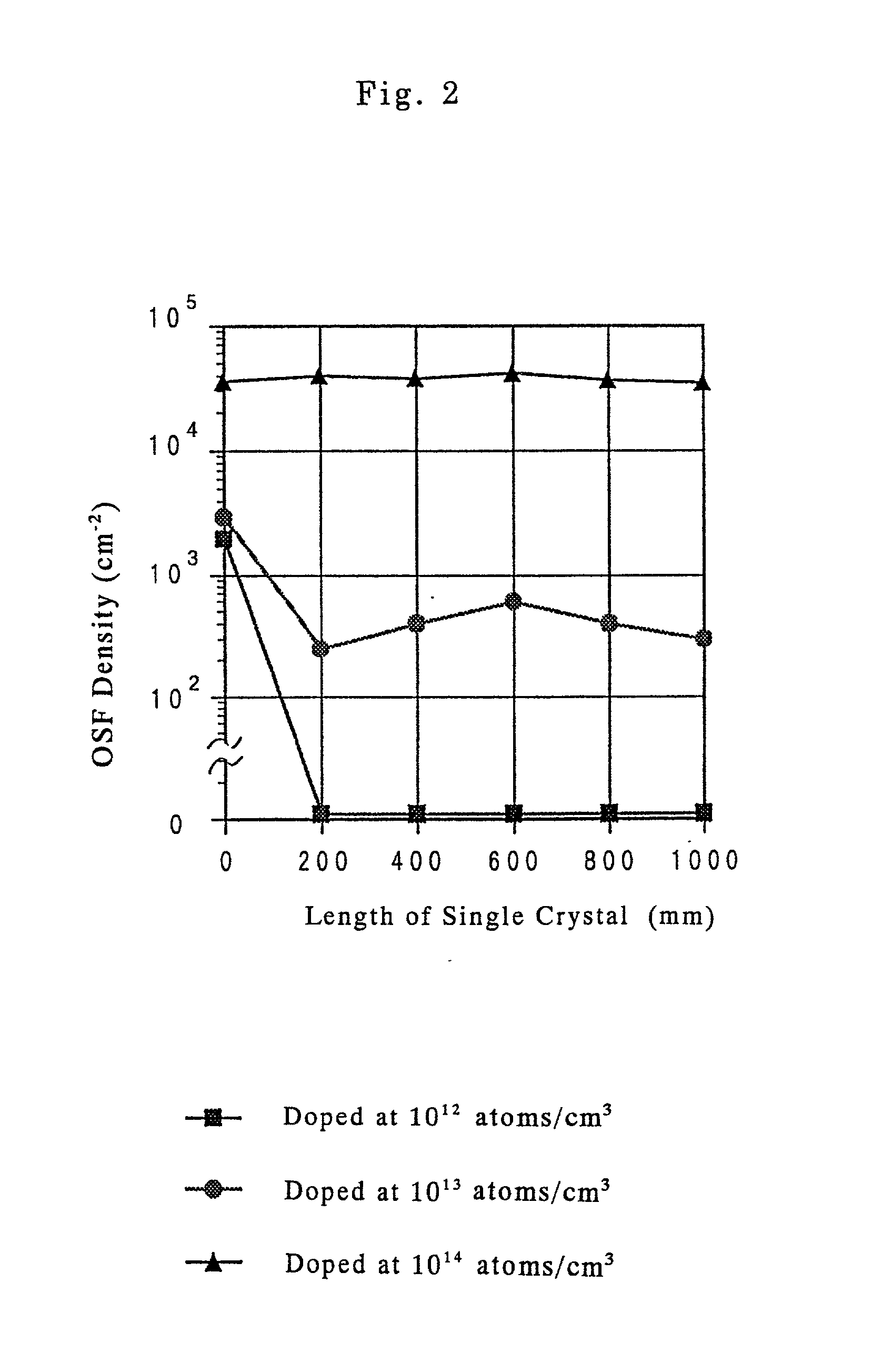

[0051] First, in order to clarify the effect of nitrogen, nitrogen gas was blown into the crucible at a rate of 10 l / min in order to increase nitrogen concentration in the crystal during the crystal growth step, when a single crystal was grown to a length of 300 mm below a shoulder. Next, in order to easily assume a nitrogen doping concentration, three grades of nitrogen-doped single crystals having respective doping concentrations of 10.sup.12 atoms / cm.sup.3, 10.sup.13 atoms / cm.sup.3, and 10.sup.14 atoms / cm.sup.3 were grown by melting a silicon wafer having a silicon nitride layer possessing a predetermined nitrogen content together with highly p...

example 2

[0055] On the single crystal silicon wafer doped with nitrogen at a concentration of 10.sup.14 atoms / cm.sup.3 in Example 1, an approximately 5-.mu.m-thick epitaxial layer was formed at a deposition temperature of 1150.degree. C. The thus-obtained wafer was then subjected to selective etching in a wright etchant for 5 minutes. The defect densities on the surface and the cross sections of the epitaxial layer were determined under an optical microscope.

[0056] FIG. 3 shows the defect densities on the surface and cross sections at various radial distances from the center of the specimens. After formation of the epitaxial layer, defects are present at a density of approximately 1.times.10.sup.4 / cm.sup.2 along the cross sections of nitrogen-doped single crystal silicon wafer under the epitaxial layer. This indicates that oxide precipitates may not be diminished during formation of the epitaxial layer at high temperature. However, defects were observed on neither the surface nor the cross s...

example 3

[0057] Nitrogen doping was carried out at respective concentrations of 0, 10.sup.12 atoms / cm.sup.3, 10.sup.13 atoms / cm.sup.3, and 10.sup.14 atoms / cm.sup.3, on two types of wafer substrates; more specifically, on a wafer substrate having a high electric resistance of 10 .OMEGA..multidot.cm and on a wafer substrate having a low electric resistance of 0.008 .OMEGA..multidot.cm. From the thus-obtained eight types of single crystals, wafer substrates were sliced and subjected to deposition at 1150.degree. C. to form an epitaxial layer having a thickness of approximately 5 .mu.m.

[0058] These wafers were contaminated with a 3 ppm aqueous solution of Cu(NO.sub.3).sub.2 by use of a spin coater, then subjected to a heat treatment in a dry oxygen atmosphere as a model treatment simulating the device production process, to thereby investigate the change in the gettering effect during heat treatment.

[0059] FIG. 4 shows a temperature-time profile of the model heat treatment. At the three time poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com