Electron beam ion source with integral low-temperature vaporizer

a technology of ion source and low-temperature vaporizer, which is applied in the direction of instruments, electric discharge lamps, material analysis, etc., can solve the problems of reducing the conductance of the beam, limiting the ion implantation technology to effectively implant the dopant species at low (e.g., sub-kev) energies, and vignetting beam loss, so as to minimize the conductance and maximize the conductance , the effect of substantially reducing the hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

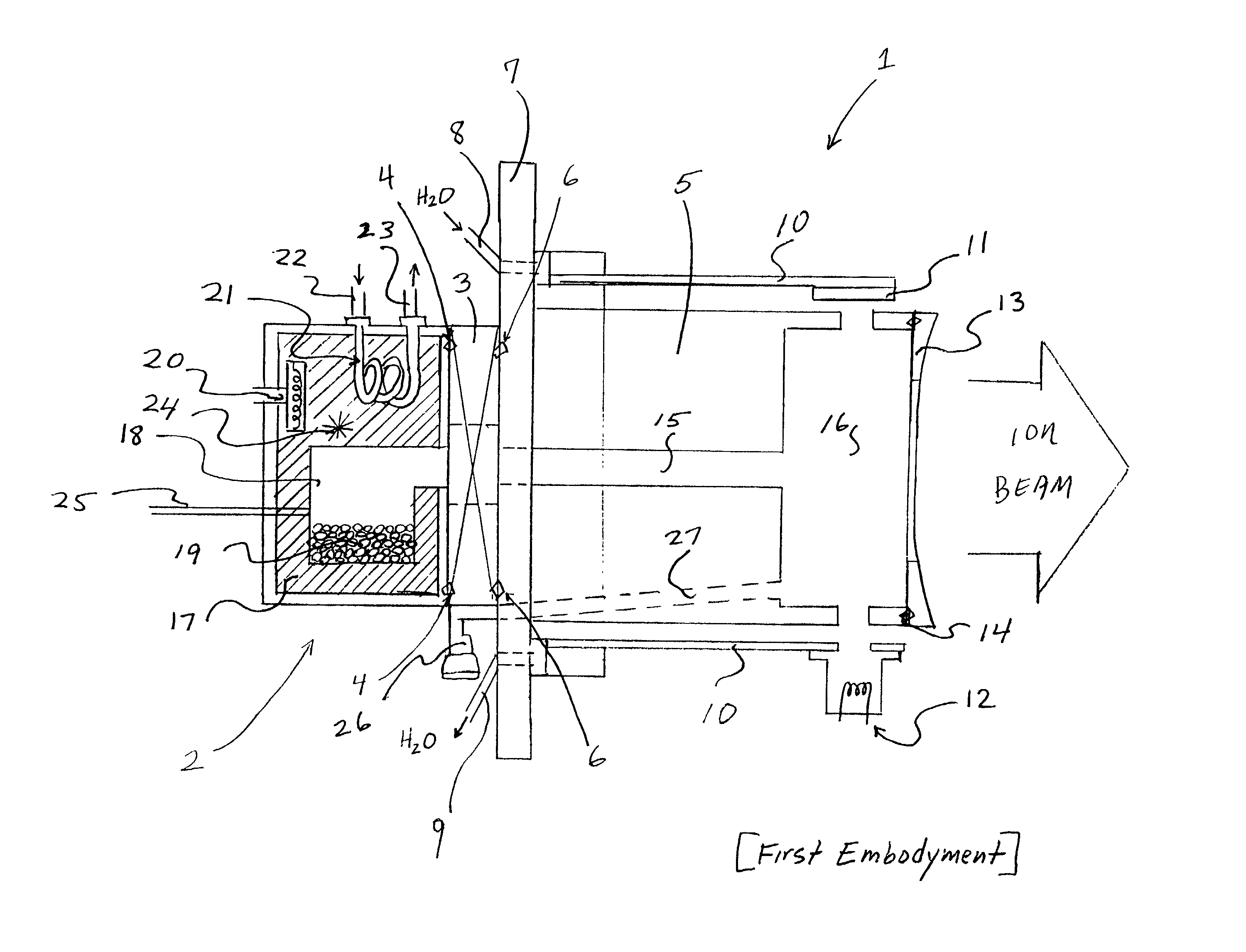

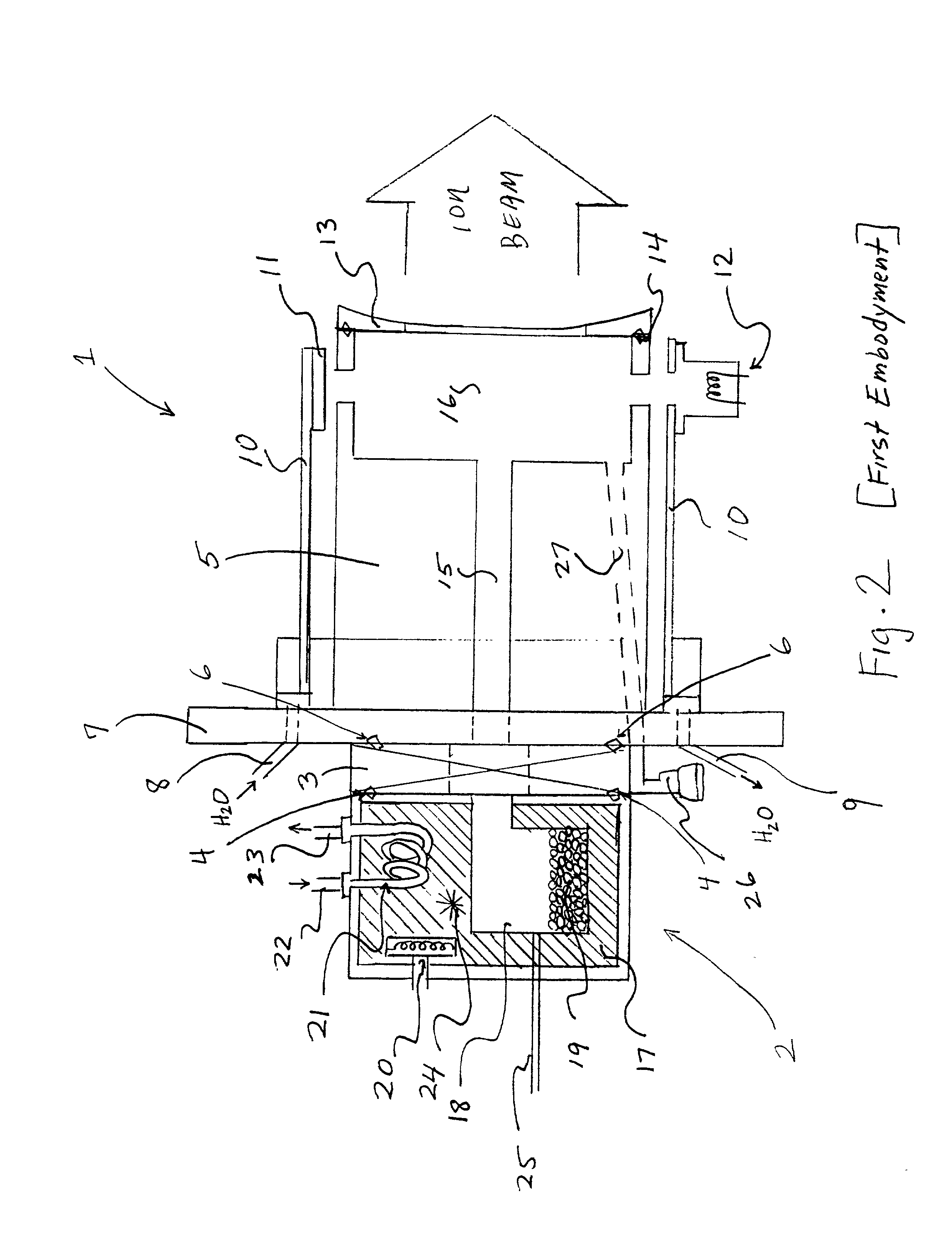

[0045] We refer now to the attached FIG. 2 through FIG. 7. FIG. 2 shows in schematic the first embodyment of the ion source 1. The vaporizer 2 is attached to the vaporizer valve 3 through a annular metal gasket 4. The vaporizer valve 3 is likewise attached to the ionization chamber 5 by a second annular metal gasket 6. This ensures good thermal conduction between the vaporizer, vaporizer valve, and ionization chamber 5 through intimate contact via thermally conductive elements. A mounting flange 7 attached to the ionization chamber 7 allows mounting of the ion source 1 to the vacuum housing of an ion implanter, and contains electrical feedthroughs (not shown) to power the ion source, and water-cooling feedthroughs 8, 9 to cool the ion source. In the preferred embodyment of the invention, water feedthroughs 8, 9 circulate water through the source shield 10 to cool the source shield 10 and cool the attached components, the beam dump 11 and electron gun 12. The exit aperture 13 is moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com