Method for forming high-entropy alloy by using added material manufacturing technology

A high-entropy alloy and additive manufacturing technology, which is applied in the AlCoCuFeNi high-entropy alloy powder material system and the field of additive manufacturing of high-performance high-entropy alloys, can solve the practical application requirements of unfavorable high-entropy alloys, difficult to form complex structural parts, cooling Slow speed and other problems, to achieve the effect of improving utilization rate and production efficiency, solving the easy segregation of alloy components, and reducing device production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

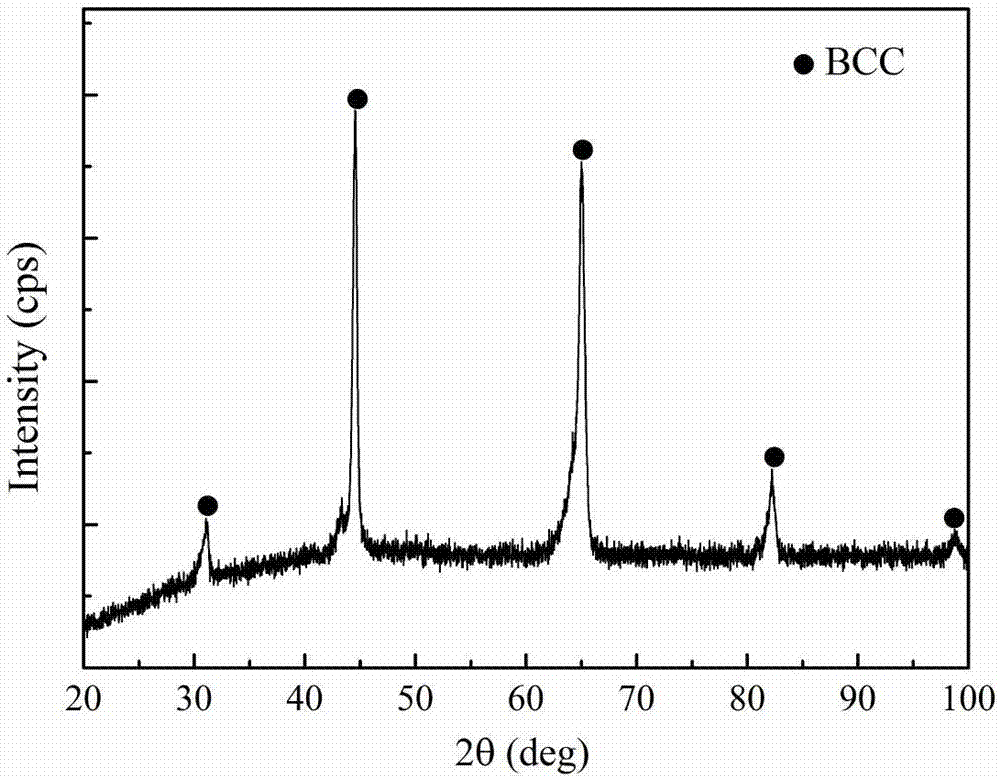

[0032] In this embodiment, the forming process of high-entropy alloy prepared by selective laser melting technology is as follows:

[0033] Model building: use SolidWorks 3D software to build a 3D digital model of the formed part, output it as an STL format file, and incorporate the model file into the selective laser melting equipment;

[0034] Raw material preparation: According to the molar ratio of each atom in the high-entropy alloy Al:Co:Cu:Fe:Ni=1:1:1:1:1:1, the bulk raw materials are accurately weighed and proportioned, and prepared by gas atomization process Pre-alloyed powder, the pre-alloyed powder is sieved, and the selected particle size is 10-55 μm;

[0035] Alloy forming: Selective laser melting equipment is used to form the alloy; the pre-alloyed powder is placed in the powder supply cylinder of the selective laser melting equipment, and the forming chamber is evacuated. When the vacuum degree reaches 1×10 -4 ~1×10 -2 After Pa, fill the molding chamber with a...

Embodiment 2

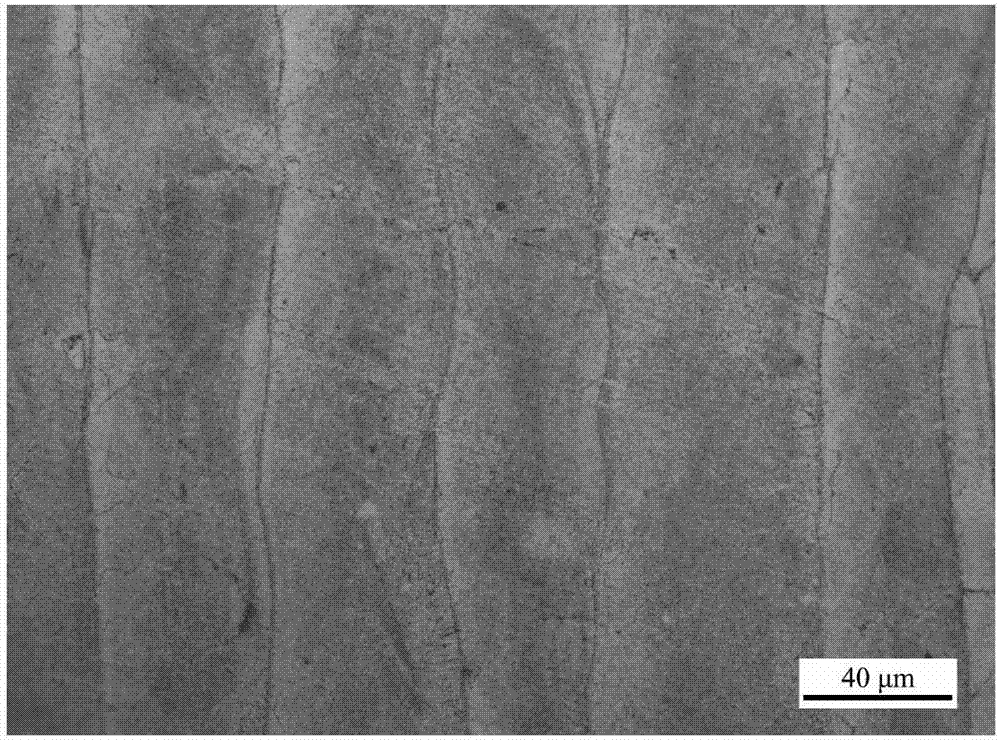

[0038] In this embodiment, the laser near-net-shape rapid prototyping technology is used to directly prepare the high-entropy alloy forming process as follows:

[0039] Model building: use SolidWorks 3D software to build a 3D digital model of the formed part, output it as an STL format file, and incorporate the model file into the laser near-net-shape rapid prototyping equipment;

[0040] Raw material preparation: According to the molar ratio of each atom in the high-entropy alloy Al:Co:Cu:Fe:Ni=1:1:1:1:1:1, the bulk raw materials are accurately weighed and proportioned, and prepared by gas atomization process Pre-alloyed powder, the pre-alloyed powder is sieved, and the selected particle size is 50-175 μm;

[0041]Alloy forming: the alloy is prepared by laser near-net-shape rapid prototyping equipment; the pre-alloyed powder is placed in the powder feeder of the laser near-net-shape manufacturing equipment, and the working distance between the laser head and the substrate is ...

Embodiment 3

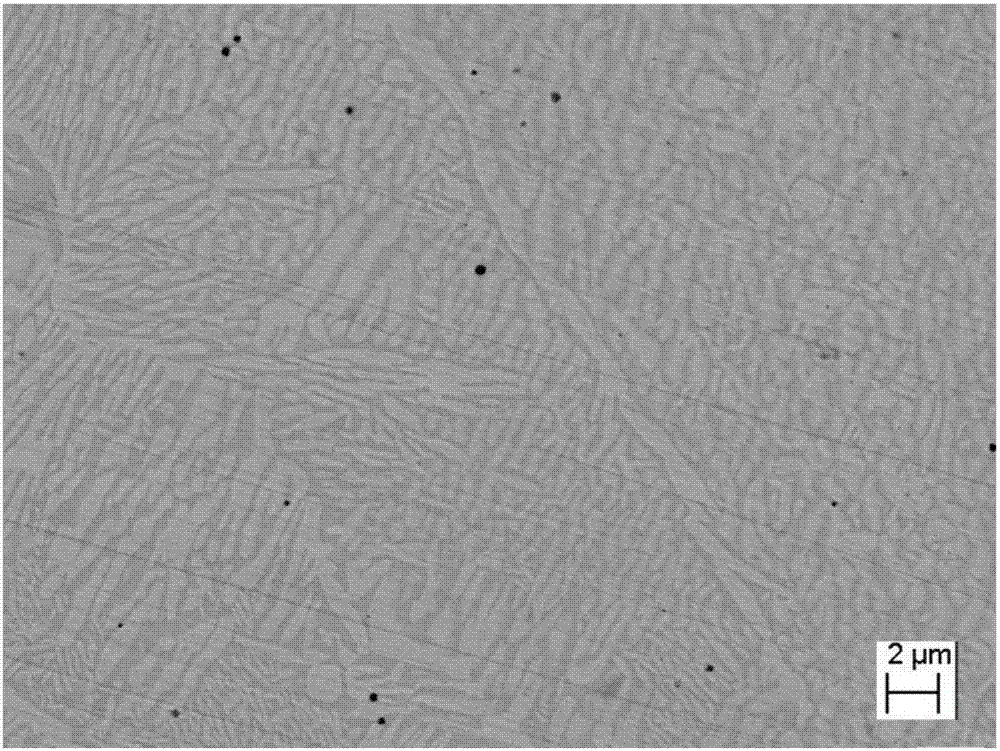

[0043] In this embodiment, the forming process of high-entropy alloy prepared by electron beam selective melting technology is as follows:

[0044] Model building: use SolidWorks 3D software to build a 3D digital model of the formed part, output it as an STL format file, and incorporate the model file into the electron beam selection melting forming equipment;

[0045] Raw material preparation: According to the molar ratio of each atom in the high-entropy alloy Al:Co:Cu:Fe:Ni=1:1:1:1:1:1, the bulk raw materials are accurately weighed and proportioned, and prepared by gas atomization process Pre-alloyed powder, the pre-alloyed powder is sieved, and the selected particle size is 35-125 μm;

[0046] Alloy forming: the alloy is formed by electron beam selective melting equipment; the pre-alloyed powder and metal substrate are placed in the forming room and leveled, and the forming room is evacuated to 1×10 -4 ~1×10 -2 After Pa, filled with helium to prevent the high entropy allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com