Converse welding method of high power LED chip

A LED chip, high-power technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as thermal stress, lattice defects, shortening the life of LED chips, etc., to prolong life, improve thermal expansion matching performance, The effect of improving the luminous efficiency of the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The method of the present invention will be further described below in conjunction with the drawings, but it is not limited thereto.

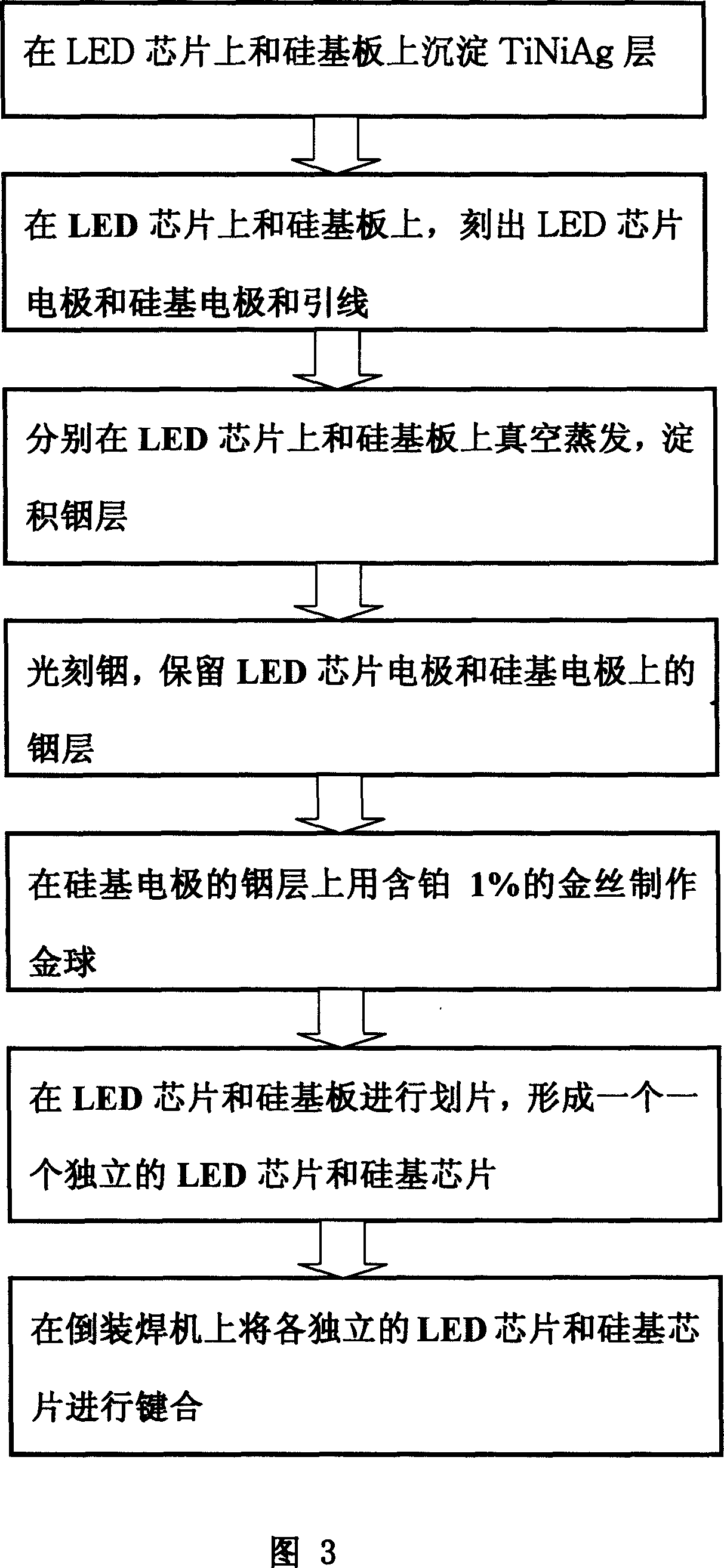

[0020] As shown in the figure, the present invention is to flip-chip the LED chip (including the sapphire substrate 6 and the GaN epitaxial layer 5 fabricated on the sapphire substrate 6) that emits light from the back side in a prefabricated fabric with multiple surge limiting and electrostatic Protect the circuit on the silicon substrate 11. The specific assembly and welding process is shown in Figure 3, including the following steps:

[0021] 1. The GaN epitaxial layer 5 fabricated on the LED chip sapphire substrate is metalized by a conventional integrated circuit vacuum coating method, and a TiNiAg (titanium nickel silver) layer 7 is formed on the surface, with titanium as the contact adhesion layer and nickel as The barrier layer, silver is used as a reflective conductive layer.

[0022] 2. Using conventional photolithography, the TiNi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com