Zinc oxide based film transistor and chip preparing process

A thin-film transistor, zinc oxide-based technology, applied in the field of microelectronics, can solve the problems of reduced reliability, low effective mobility, and rising manufacturing costs, and achieve the effects of improving interface characteristics, avoiding cross-contamination, and improving interface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. ITO conductive glass cleaning

[0042] Ultrasonic cleaning of the ITO substrate, first with carbon tetrachloride, then with acetone, then with absolute ethanol, and finally blown dry with nitrogen;

[0043] 2. ITO conductive glass photolithography, making TFT structure device unit graphics

[0044] (1) Coating photoresist on the front of the ITO conductive glass with a thickness of about 0.8-0.9 μm;

[0045] (2) Pre-bake on a hot plate to dry the photoresist, the condition is 70-90°C, and bake for 70-100 seconds;

[0046] (3) Photolithography machine exposure, the exposure time is 20 seconds;

[0047] (4) Immerse in developing solution and develop for 15 seconds to make ITO isolated island structure unit pattern;

[0048] (5) ion etching to remove the bottom film for 30 seconds;

[0049] 3. Corrosion of ITO

[0050] Preparation of corrosion solution HCl: H 2 O: HNO 3 =3:2:1, heating in 50°C water bath, corrosion time 40s~60s;

[0051] 4. Epitaxial growth of h...

Embodiment 2

[0076] 1. ITO conductive glass cleaning

[0077] Ultrasonic cleaning of the ITO substrate, first with carbon tetrachloride, then with acetone, then with absolute ethanol, and finally blown dry with nitrogen;

[0078] 2. ITO conductive glass cleaning, photolithography, making TFT structure device unit graphics

[0079] (1) Coating positive photoresist on the front of the ITO conductive glass with a thickness of 0.8-0.9 μm;

[0080] (2) Pre-baking on a hot plate to dry the photoresist at 70-90°C for 70-100 seconds;

[0081] (3) Photolithography machine exposure, the exposure time is 20 seconds;

[0082] (4) Immerse in developing solution and develop for 15 seconds to make ITO isolated island structure unit pattern;

[0083] (5) ion etching to remove the bottom film for 30 seconds;

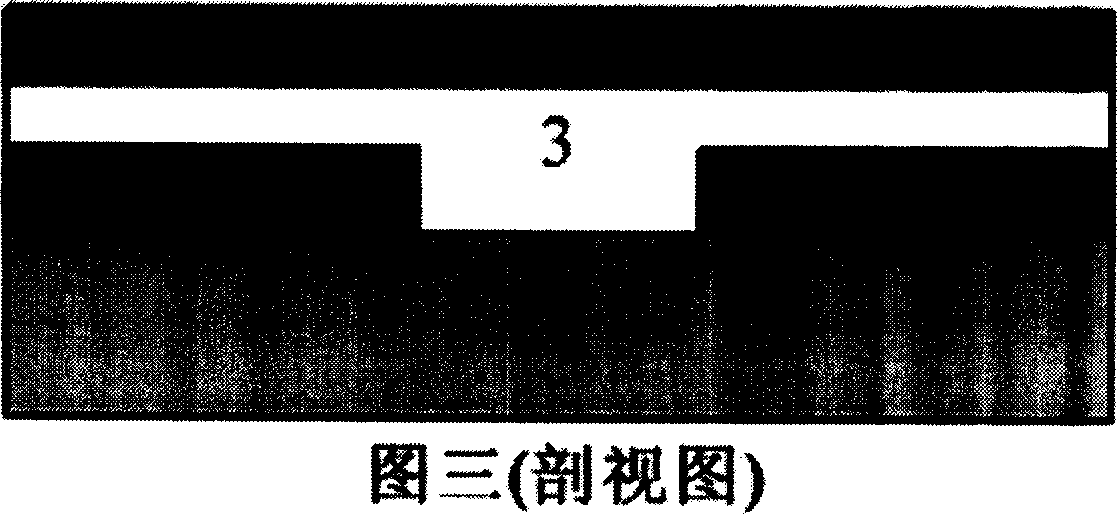

[0084] 3. Corrosion of ITO, see Figure 1

[0085] Preparation of corrosion solution HCl: H 2 O: HNO 3 =3:2:1, 50°C water bath heating, corrosion time 40 seconds to 60 seconds;

[0086] 4. Ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com