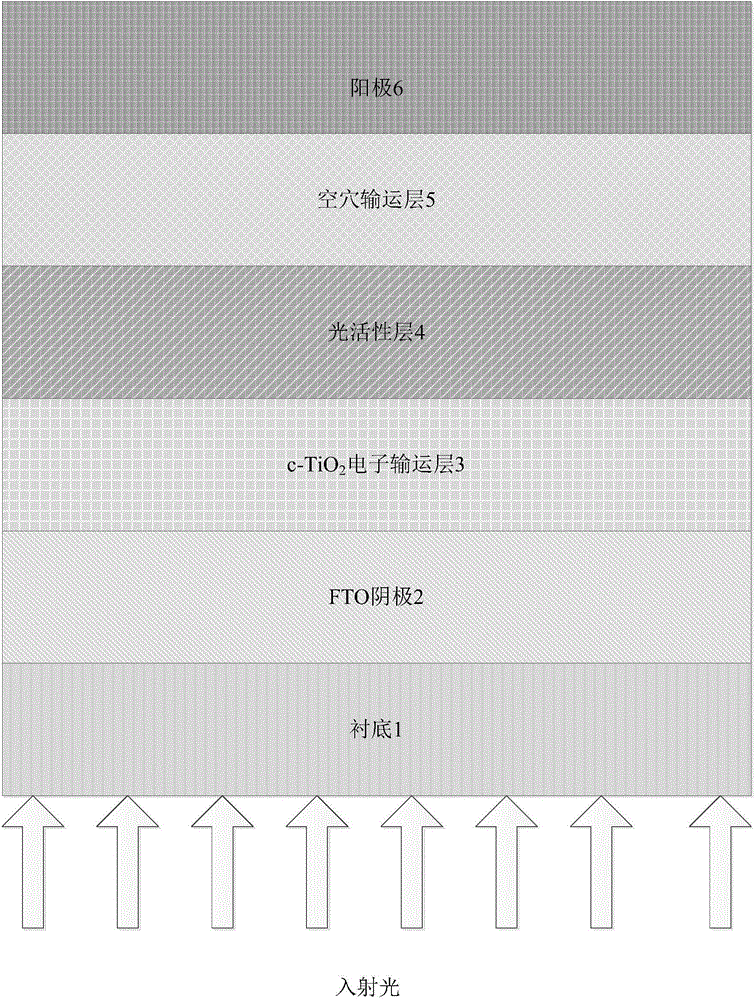

Plane perovskite solar cell based on FTO/c-TiO2 cathode and manufacturing method of plane perovskite solar cell

A solar cell and perovskite technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of incompatibility, complex process, high cost, etc., and achieve large-area thin film preparation, simplified process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

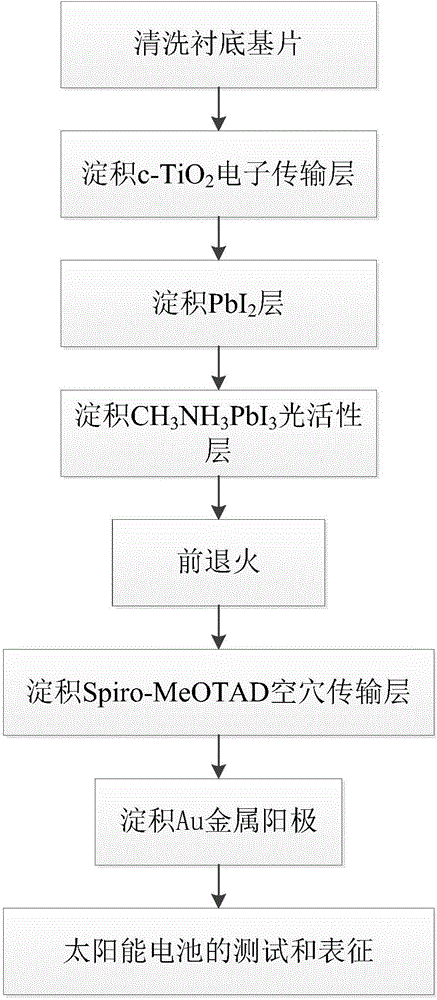

[0031] Example 1, making dense titanium dioxide c-TiO 2 A solar cell with a thickness of 70nm.

[0032] Step 1, cleaning the substrate substrate.

[0033] The 1.9mm glass substrate with fluorine-doped tin oxide FTO was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 10 min in turn, and dried with a nitrogen gun after cleaning.

[0034] Step 2, Deposit c-TiO 2 electron transport layer.

[0035] 2a) Preparation of precursor solution:

[0036] First take 21.464mL of 75% mass fraction of diisopropyl diacetylacetonate titanate TiAc solution, and add 18.536mL of 1-butanol to the solution to dilute, and sonicate the diluted solution for 10min to obtain a concentration of 0.15 M / L c-TiO 2 Precursor solution;

[0037]Then take 2.928mL of 75% mass fraction of diisopropyl diacetylacetonate titanate TiAc solution, and add 17.072mL of 1-butanol to the solution for dilution, and ultrasonically treat the diluted solution for 10min to obtain ...

Embodiment 2

[0055] Example 2, making dense titanium dioxide c-TiO 2 A solar cell with a thickness of 85nm.

[0056] Step 1, cleaning the substrate substrate.

[0057] The 1.9 mm glass substrate containing fluorine-doped tin oxide FTO was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 minutes, and dried with a nitrogen gun after cleaning.

[0058] Step 2, depositing c-TiO 2 electron transport layer.

[0059] 2.1) Preparation of precursor solution:

[0060] The concrete realization of this step is identical with step 2a) of embodiment 1;

[0061] 2.2) Spin coating c-TiO 2 Precursor solution:

[0062] Spin-coat 0.15M / L c-TiO for the first time on the substrate after step 1 2 For the precursor solution, the spin coating speed is 6000r / min, the time is 60s, and annealed in an oven at a temperature of 125°C for 5min;

[0063] Then spin-coated 0.15M / L c-TiO 2 The second spin-coating of 0.3M / L c-TiO on the substrate of the precursor soluti...

Embodiment 3

[0078] Example 3, making dense titanium dioxide c-TiO 2 A solar cell with a thickness of 100nm.

[0079] Step A, cleaning the substrate substrate.

[0080] The 1.9 mm glass substrate containing fluorine-doped tin oxide FTO was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 20 minutes, and dried with a nitrogen gun after cleaning.

[0081] Step B, depositing c-TiO 2 electron transport layer.

[0082] B1) Preparation of precursor solution:

[0083] The concrete realization of this step is identical with the step 2a) of embodiment one;

[0084] B2) Spin-coating c-TiO 2 Precursor solution:

[0085] B21) Spin-coat 0.15M / L c-TiO for the first time with 6000r / min and 60s spin-coating time on the substrate after step A 2 Precursor solution, and annealed in an oven at a temperature of 125 ° C for 5 min;

[0086] B22) After spin-coating 0.15M / L c-TiO 2 On the substrate of the precursor solution, spin-coat 0.3M / L c-TiO for the second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com