Manufacturing method of lithium ion battery containing gel electrolyte

A gel electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of high-current charge-discharge performance and low-temperature charge-discharge performance deterioration, poor conductivity, battery capacity decline, etc., to achieve excellent charge-discharge performance, high Effect of initial voltage and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

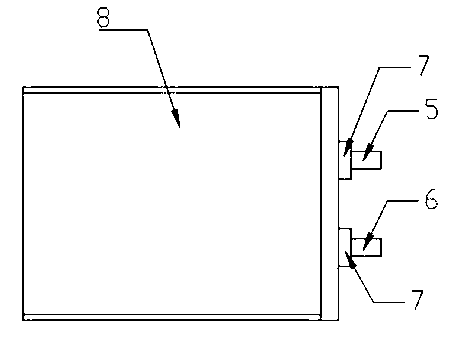

[0050] (2) Preparation of anode electrode sheet: According to the battery design, add the anode active material, conductive agent and binder into the solvent (such as water) in a certain proportion, disperse evenly, form a uniform cathode slurry, and then evenly coat Or rolled onto the anode current collector, then dried and rolled, and finally, an anode tab 6 is welded on the part of the anode current collector not covered with the anode slurry, and the contact between the anode tab 6 and the packaging material layer 8 is covered with a sealant 7 Wrapping to obtain the anode pole piece.

[0051] (3) Assembly of battery cells: the prepared cathode pole piece and anode pole piece are separated by a microporous separator plate 2 to form a laminated structure, and the battery core is formed by winding or stacking.

[0052] (4) Encapsulation of the electric core: place the prepared electric core in the packaging material layer 8, and perform sealing and encapsulation by means of t...

Embodiment 1

[0060] The first step, the preparation of microporous isolation membrane plate 2: dissolve methyl acrylate in deionized water to form a uniform solution, and then add liquid-absorbing polyvinylidene fluoride, wherein the mass ratio of methyl acrylate to polyvinylidene fluoride is 1 / 4, in the process of dispersing polyvinylidene fluoride, a small amount of co-solvent chloroform is added, and after a uniform solution is formed, nano-alumina powder with a particle size of 10nm~50nm is added, and nano-alumina powder and polyvinylidene fluoride The mass ratio is 1 / 1, the dispersion is uniform, and a uniform emulsion is formed. The mass ratio of methyl acrylate to the uniform emulsion is 1%, and then the obtained uniform emulsion is evenly sprayed on the matrix polymer film polyethylene film, and the solvent water dry to obtain the microporous isolation membrane plate 2.

[0061] The second step is the preparation of the cell.

[0062] (1) Preparation of the cathode sheet: LiCoO as...

Embodiment 2

[0073] The difference between Example 2 and Example 1 is that the raw material used to prepare the crosslinked body of the gel electrolyte is ethyl acrylate, the absorbent is polyacrylonitrile, and the mass ratio of ethyl acrylate to polyacrylonitrile It is 3 / 10, the solvent in the first step is acetone, and the mass percentage that ethyl acrylate accounts for the total mass of the homogeneous solution of the first step is 1%, the cosolvent is toluene, and the mass percentage that the initiator accounts for the liquid electrolyte is 0.5% . Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com