High-capacity hydrogen-storage material with NaAlH4 and preparation method thereof

A hydrogen storage material and a hydride technology are applied in the field of high-capacity coordination sodium-aluminum hydride hydrogen storage materials and their preparation, which can solve the problems of reducing effective hydrogen storage components, consumption of hydrogen storage materials, capacity loss, and the like, and achieve low prices. , Simple process, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Ti-doped NaAlH by Composite Doping KH and Ti Powder Using NaH / Al Powder Mixture as Matrix 4 Hydrogen storage material.

[0031] The raw materials used are: NaH (purity 95%, ~200 mesh), KH (dispersed in mineral oil, 30% by weight), Al powder (purity 99.95+%, ~200 mesh), and Ti powder (purity 99.98%, ~325 mesh). Except for KH, other raw materials were used directly without treatment. KH was extracted from mineral oil with pentane in an argon atmosphere glove box. After several pentane washes and filtration, the pentane was vacuum removed to obtain pure KH. Put the raw material mixture with a molar ratio of 0.96NaH+Al+0.04Ti+0.04KH into a stainless steel ball mill jar, and grind it on a Fritsch 7 planetary ball mill for 10 hours. The ball milling atmosphere is high-purity hydrogen (purity 99.999%), and the initial pressure is about 8 atmospheres. The ball-to-material ratio is 40:1.

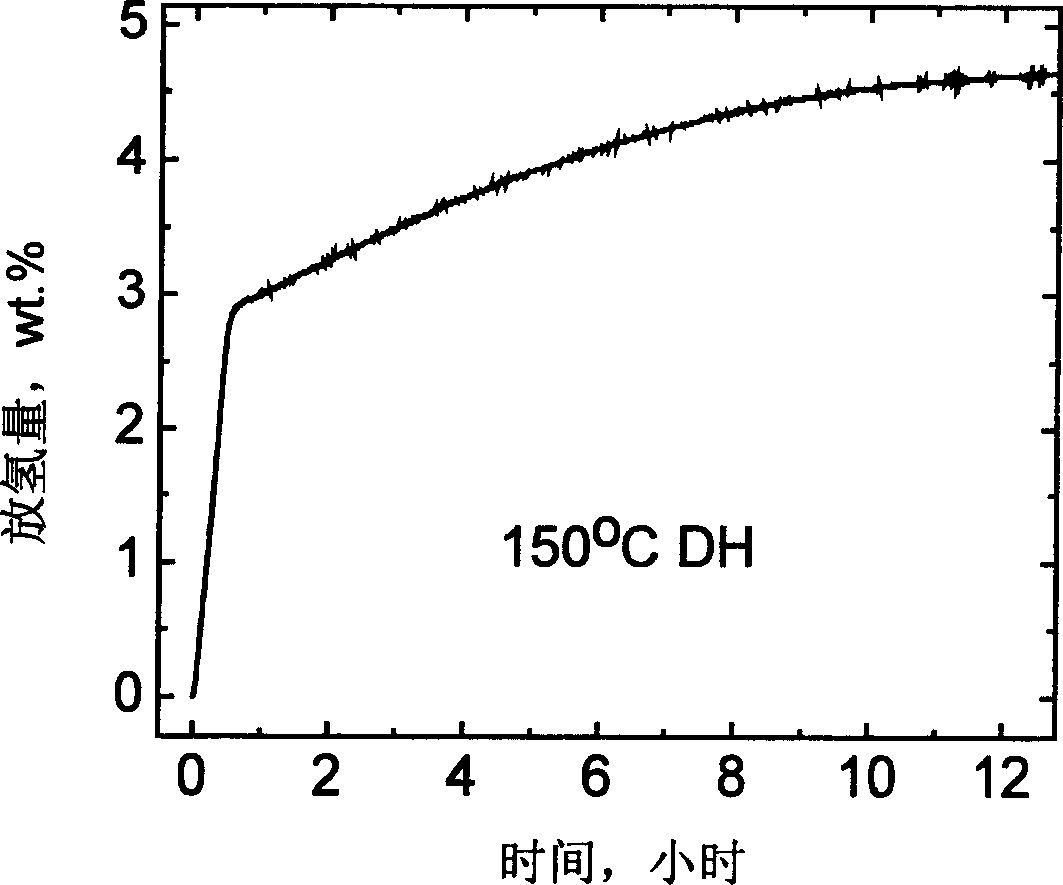

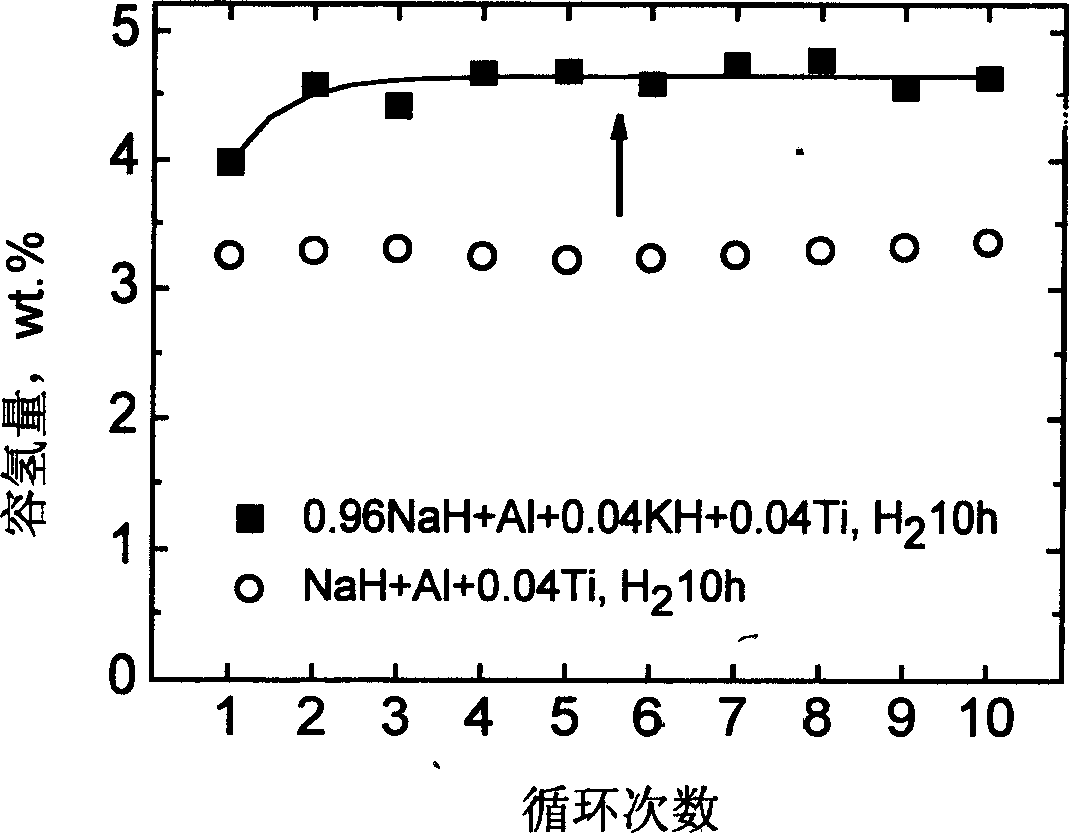

[0032] The hydrogen absorption and desorption properties of the materi...

Embodiment 2

[0036] NaAlH Prepared by Composite Doping KH and Ni Powder Based on NaH / Al Powder Mixture 4 Hydrogen storage material.

[0037] Ni powder (purity 99.99%, ~100 mesh) in the raw material is used, NaH, Al powder and KH are the same as embodiment 1. The starting materials with a molar ratio of 0.95NaH+Al+0.05Ni+0.05KH were put into a stainless steel ball mill jar and ground on a Fritsch 7 planetary ball mill for 20 hours. The ball milling atmosphere is high-purity argon (purity 99.999%), and the initial pressure is 1 atmosphere. The ball-to-material ratio is 60:1.

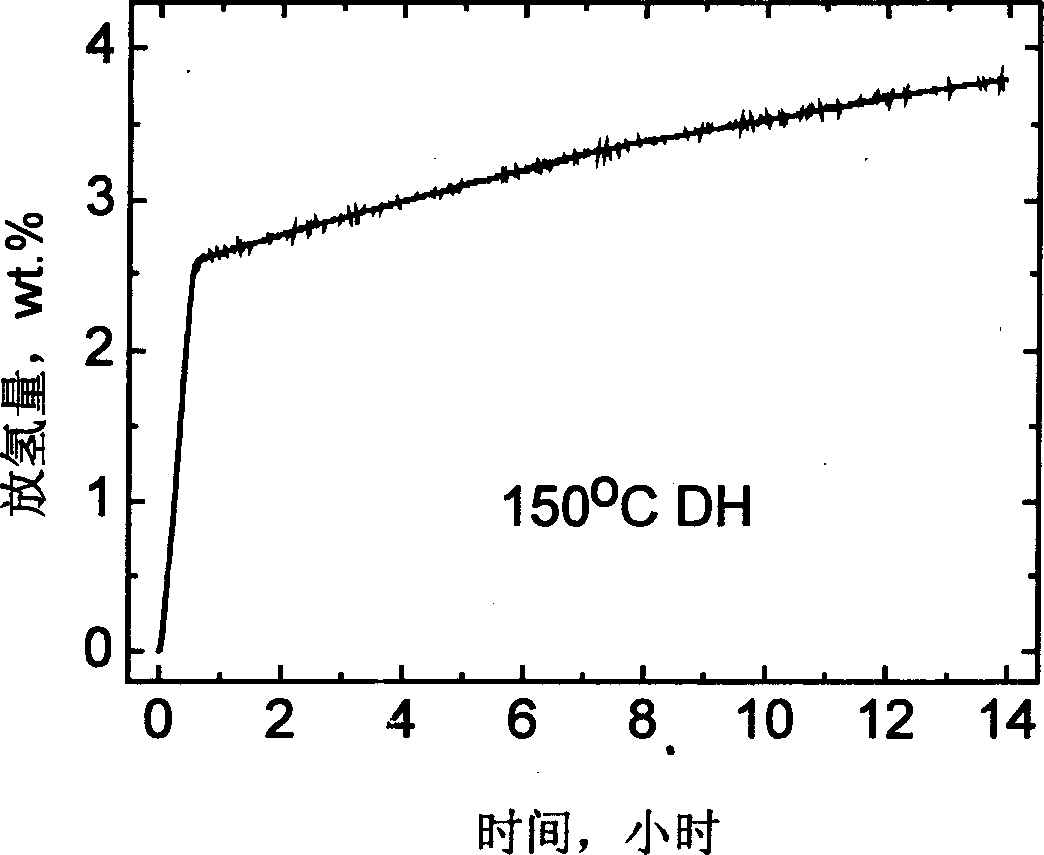

[0038] Such as image 3 Shown: In the second cycle, the material released hydrogen at 150°C for 14 hours, and the amount of hydrogen released could reach 3.8wt.%; it took about 15 hours to absorb hydrogen at 120°C. The material has stable hydrogen capacity and dynamic performance in the hydrogen absorption and desorption cycle.

Embodiment 3

[0040] Composite doping of CaH with NaH / Al powder mixture as matrix 2 Preparation of Ti-doped NaAlH with Ti powder 4 Hydrogen storage material.

[0041] Using MgH in the raw material 2 (purity 95%,~40 orders), NaH, Al powder and Ti powder are the same as embodiment 1. The molar ratio will be 0.96NaH+Al+0.04Ti+0.02MgH 2 Proportioned starting materials were placed in a stainless steel ball mill jar and ground on a Fritsch 7 planetary ball mill for 10 hours. The ball milling atmosphere is high-purity hydrogen (purity 99.999%), and the initial pressure is 10 atmospheres. The ball-to-material ratio is 50:1.

[0042] Such as Figure 4 Shown: In the third cycle, the material released hydrogen at 150°C for 15 hours, and the amount of hydrogen released could reach 4.0wt.%; at 120°C, it took about 20 hours to absorb hydrogen saturatedly. The material has stable hydrogen capacity and dynamic performance in the hydrogen absorption and desorption cycle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com