Low-temperature sintering production technology for magnetic ferrite and inductive material

A magnetic ferrite, low-temperature sintering technology, applied in the manufacture of inductors/transformers/magnets, magnetism of inorganic materials, circuits, etc., can solve problems such as difficult miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

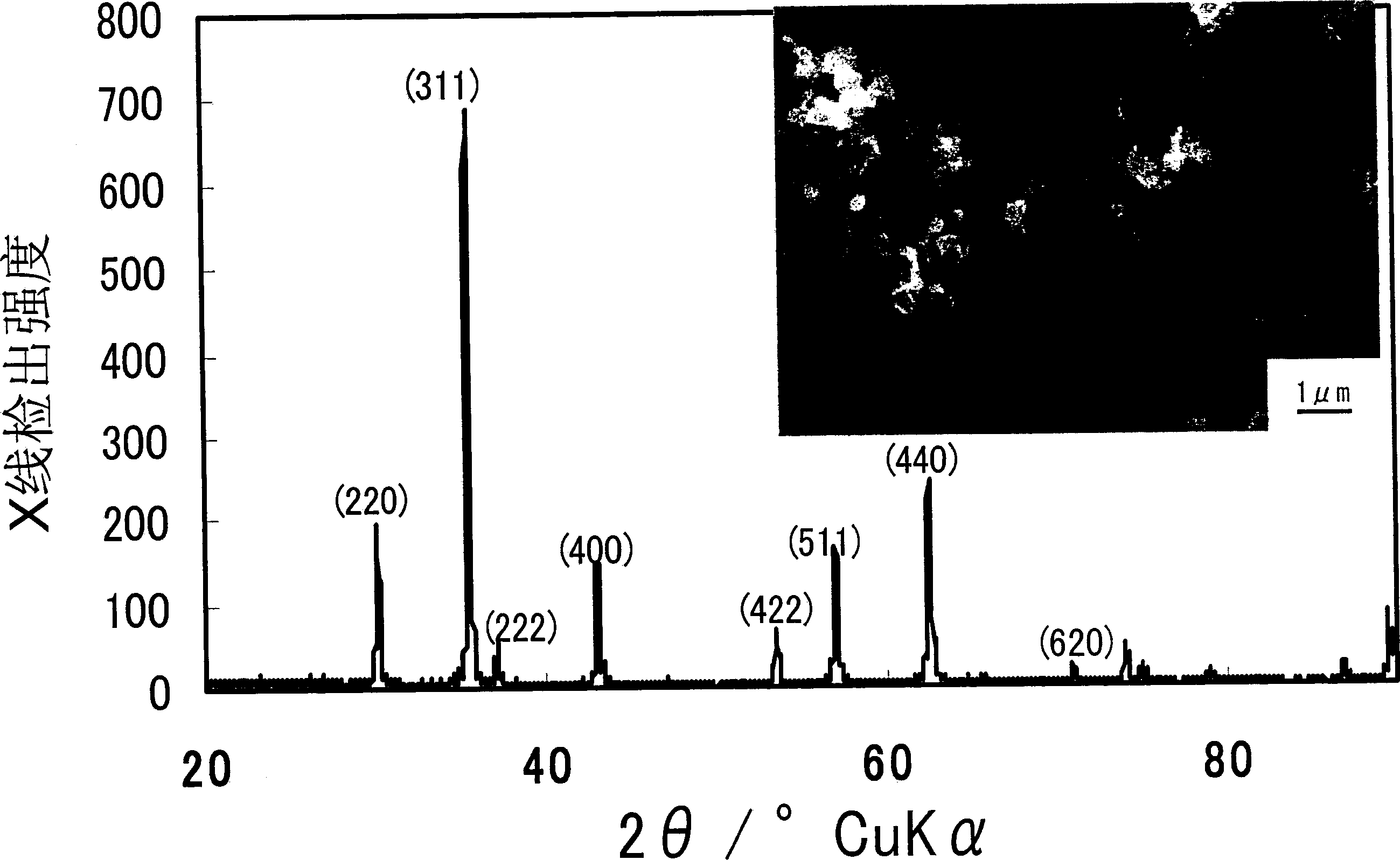

[0031] Ordinary Magnetic Ferrite Fe 3 o 4 preparation of

[0032] First, prepare a certain concentration of Fe according to a predetermined ratio 2+ and Fe 3+ Solution, take a certain amount of test solution according to the composition of ferrite, mix evenly and preheat to a certain temperature, so that the crystal powder is completely dissolved; at the same time, weigh a certain amount of ammonium oxalate according to the coprecipitation reaction ratio to make a certain concentration solution; then the two solutions were added to 100ml aqueous solution at the same time, and stirred for 1h. After fully reacting, stop stirring and cool to room temperature. The precipitate was filtered, washed and dried to produce yellow ferric oxalate powder. By controlling the pH value of the reaction system, the particle size of ferric oxalate can be controlled, and by controlling the particle size of ferric oxalate, the control of Fe 3 o 4 The particle size of the magnetic fine powde...

Embodiment 2

[0037] Prepare a certain concentration of Ba according to the predetermined ratio 2+ , Zn 2+ , Fe 2+ and Fe 3+ Solution, take a certain amount of test solution according to the composition of ferrite, mix evenly and preheat to a certain temperature; at the same time, weigh a certain amount of ammonium oxalate according to the coprecipitation reaction ratio to make a solution with a certain concentration; Both solutions were added to 100ml of aqueous solution and stirred for 1h. After fully reacting, stop stirring and cool to room temperature. The precipitate was filtered, washed and dried to make oxalate powder. By controlling the feeding rate and the pH value of the reaction system, the particle size of the oxalate can be controlled. The iron oxalate is BaZnFe 6 o 11 Precursor of magnetic sintered body.

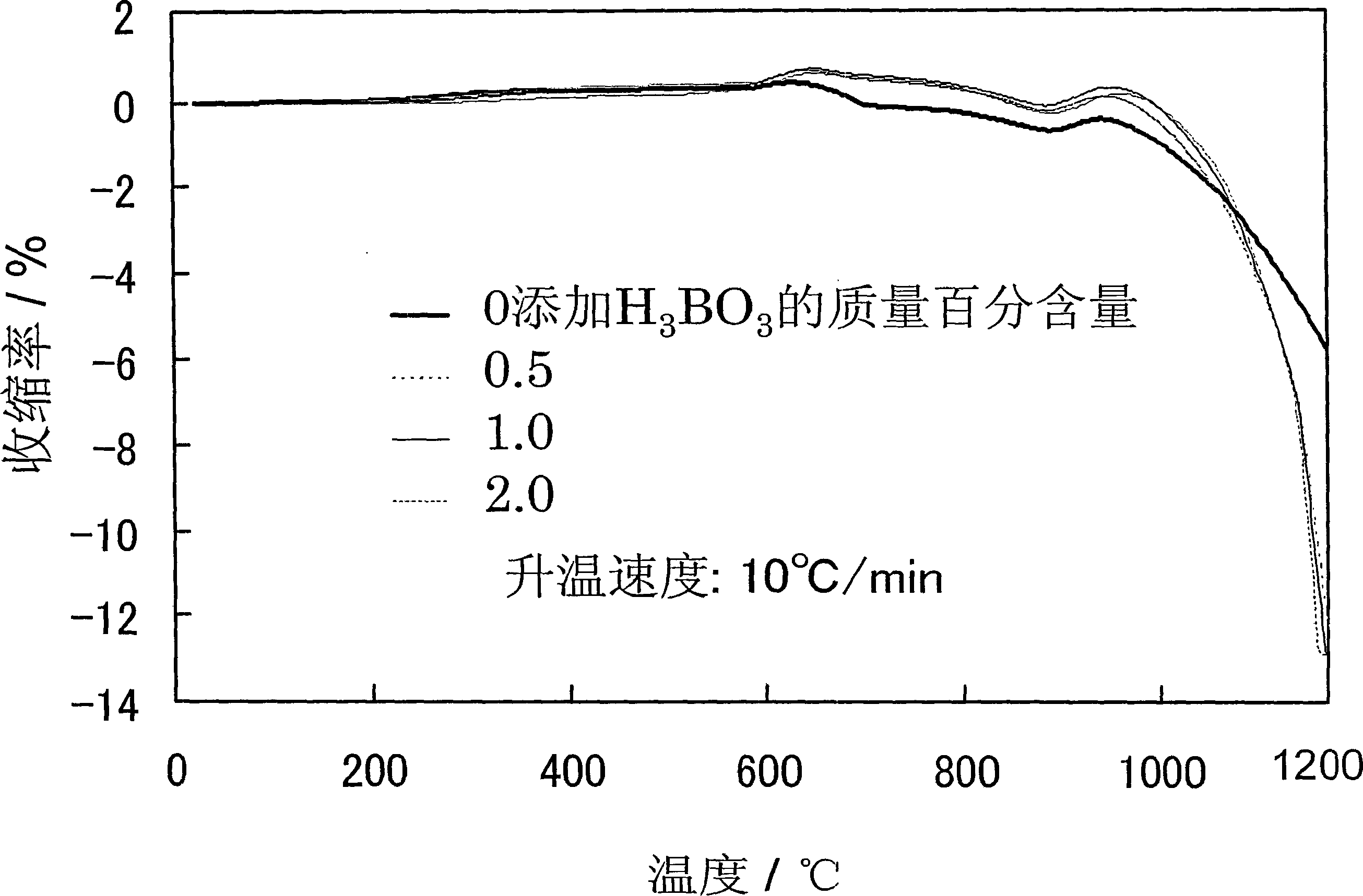

[0038] Next, put the oxalate into the quartz tube under the protective gas of carbon dioxide, take it out from the electric furnace after keeping it at 500°C for 1 h...

Embodiment 3

[0041] Prepare a certain concentration of Ba according to the predetermined ratio 2+ , Fe 2+ and Fe 3+ Solution, take a certain amount of test solution according to the composition of ferrite, mix evenly and preheat to a certain temperature; at the same time, weigh a certain amount of ammonium oxalate according to the coprecipitation reaction ratio to make a solution with a certain concentration; Both solutions were added to 100ml of aqueous solution and stirred for 1h. After fully reacting, stop stirring and cool to room temperature. The precipitate was filtered, washed and dried to produce a yellow oxalate powder. By controlling the feeding rate and the pH value of the reaction system, the particle size of the oxalate can be controlled. This oxalate is a precursor of the magnetic sintered body.

[0042] Secondly, put the oxalate into the quartz tube under the protective gas of carbon dioxide, take it out from the electric furnace after keeping it at 500°C for 1 hour, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com