Sealing agent for photoelectric conversion element and photoelectric conversion element using the same

A photoelectric conversion and sealing agent technology, which is applied in semiconductor/solid-state device parts, capacitors, photovoltaic power generation, etc., can solve the problems of low resin bonding strength, unsatisfactory sealing agent, poor operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

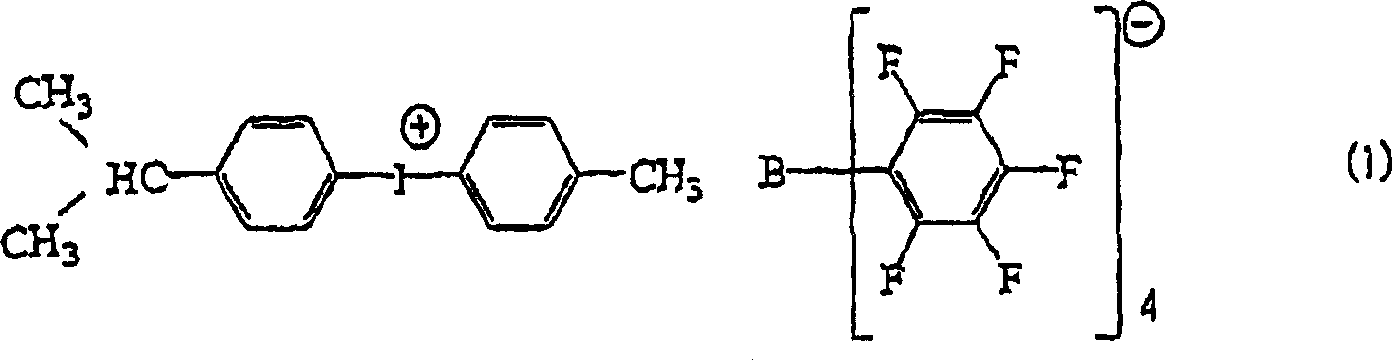

[0114] Compounds having a glycidyl structure (bisphenol A epoxy resin (RE-301S, manufactured by NipponKayaku Co., epoxy equivalent 182 g / eq, 30 parts by weight; and Epomic R301, manufactured by Mitsui Chemical Co., epoxy Equivalent 500g / eq, 10 parts by weight), a compound with an oxane structure (Celoxide2021A, manufactured by Daicel Chemical Industries, Ltd., 30 parts by weight), a compound with an oxetane structure (BPDO (biphenyldioxane Cyclobutane, manufactured by Ube Industries, Ltd.), 30 parts by weight), and a silane coupling agent (epoxysilane, Saila Ace S510, by Chisso Co., 1 part by weight), and heated at 70° C. The cooling After the mixture reaches room temperature, in the dark, add 3 parts by weight of diaryliodonium salt (represented by Chemical Formula 1, Rhodorsil photoinitiator 2074, manufactured by Rhodia Chimie Co.) as a cationic polymerization initiator, and 2 parts by weight of diaryliodonium Ethylthioxanthone (represented by the following Chemical Formula ...

Embodiment 2

[0118] According to the same method as in Example 1, the sealant (B) for photoelectric conversion devices of the present invention is obtained, the viscosity of which is about 50,000 Pa·s, the difference is that bisphenol A with an epoxy equivalent of about 250g / eq is used Epoxy resin and xylylenedioxetane (trade name XDO, manufactured by Toa Gosei Co.) were substituted for RE-301S and BPDO, respectively.

Embodiment 3

[0120] According to the same method as in Example 1, the sealant (C) for photoelectric conversion devices of the present invention is obtained, and its viscosity is about 50,000 Pa·s. The difference is that the hydrogenated product of bisphenol A epoxy resin (Adeca ResinEP 4080, manufactured by Asahi Denka Co.) was substituted for Celoxide 2021A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com