Anticorrosive magnesium-aluminium composite material and its preparing method

A composite material and corrosion-resistant technology, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of expensive treatment process, unfound process, backward process, etc., and achieve low price, excellent resistance The effect of corrosion and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0014] Dimensions will be 10 x 10 x 2mm 3 aluminum sheet, 10×10×2mm 3 Grind the fresh surface of the magnesium sheet with sandpaper, spread 0.5g of zinc powder evenly in the middle, embed it with graphite powder, compact it at room temperature, and apply an external force exceeding the yield strength of aluminum and magnesium at the holding temperature at 300°C

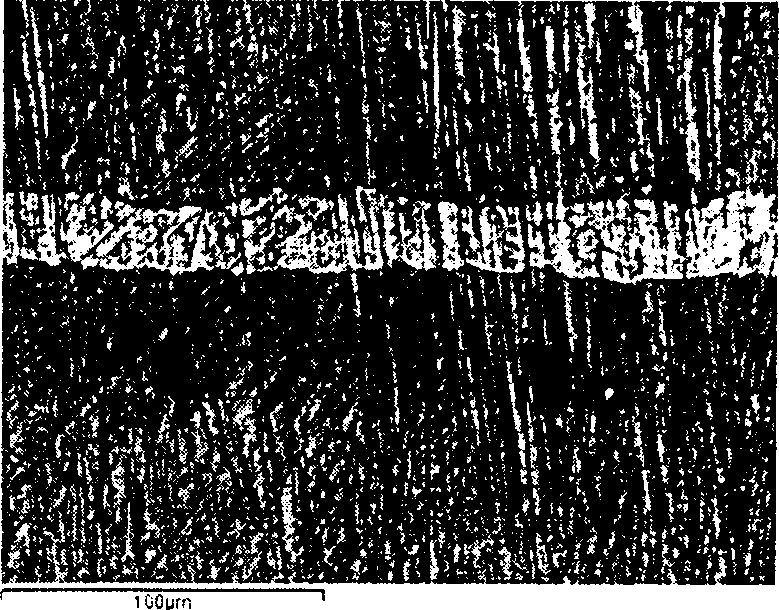

[0015] (200MPa), keep it for 35 minutes, and after cooling, a corrosion-resistant magnesium-aluminum composite material bonded by zinc as the intermediate connection layer is obtained. Scanning electron microscopy (SEM) observed that figure 1 Transition layer shown.

Embodiment approach 2

[0017] Dimensions will be 10 x 10 x 0.1mm 3 aluminum sheet, 10×10×10mm 3 Grind the fresh surface of the magnesium block with sandpaper, spread 0.5 grams of tin powder evenly in the middle, embed it with graphite powder, compact it at room temperature, and apply an external force exceeding the yield strength of aluminum and magnesium at the holding temperature at 250 °C

[0018] (200MPa), keep it for 30 minutes, and after cooling, a corrosion-resistant magnesium-aluminum composite material bonded by tin as the intermediate connection layer is obtained.

Embodiment approach 3

[0020] Dimensions will be 10 x 10 x 2mm 3 aluminum sheet, 10×10×2mm 3 The AZ91 magnesium alloy sheet is ground with sandpaper to make a fresh surface, 0.5 grams of tin-aluminum composite powder with a mass percentage of Sn+3%Al is evenly spread in the middle, embedded with graphite powder, compacted at room temperature, and applied at 250 ° C over aluminum 1. Under the external force (200MPa) of the yield strength of magnesium at the holding temperature, keep it for 35 minutes. After cooling, the corrosion-resistant magnesium-aluminum composite material combined with tin and aluminum as the intermediate connection layer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com