Prepn of nano cadmium sulfide/polystyrene core-shell microsphere

A polystyrene microsphere and polystyrene technology, which is applied in the fields of chemistry and inorganic materials, can solve problems such as complex reactions, and achieve the effects of simple operation, short production cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

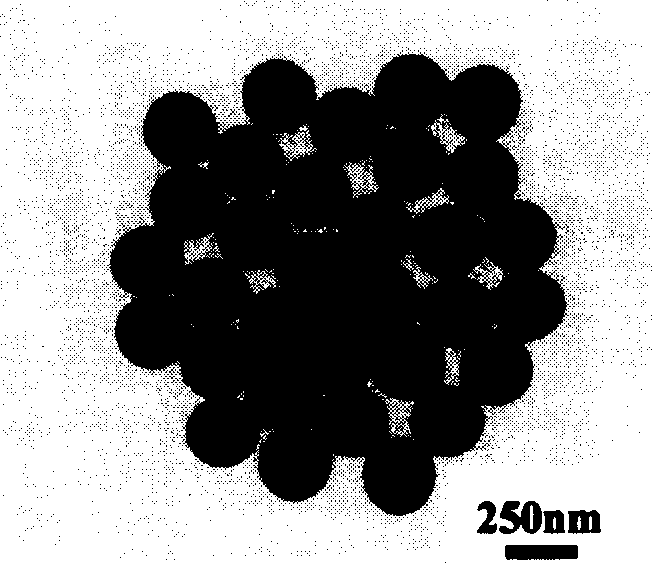

[0016] (1) Styrene, sodium lauryl sulfate, potassium persulfate and deionized water distilled under reduced pressure are mixed in a three-necked flask in a mass ratio of 100:0.3:1:574, nitrogen gas is passed for 20 minutes and the temperature is raised rapidly After stirring for 6 hours at 80° C., the emulsion was broken with sodium chloride solution, filtered and washed, and the product was dried in a vacuum oven at room temperature for 24 hours to obtain polystyrene microspheres with a diameter of 250 nanometers.

[0017] (2) Mix 50 mg of polystyrene microspheres, 436.3 mg of cadmium acetate, 123 mg of thioacetamide and 50 g of ammonia water in a 50 mL Erlenmeyer flask, sonicate for 5 minutes, then place in an oil bath and heat at 60°C. Stir for 4 hours. After the reaction is completed, it is washed with ethanol or water, centrifuged, and dried in an oven to obtain a powder which is the cadmium sulfide / polystyrene core-shell nanometer microsphere.

Embodiment 2

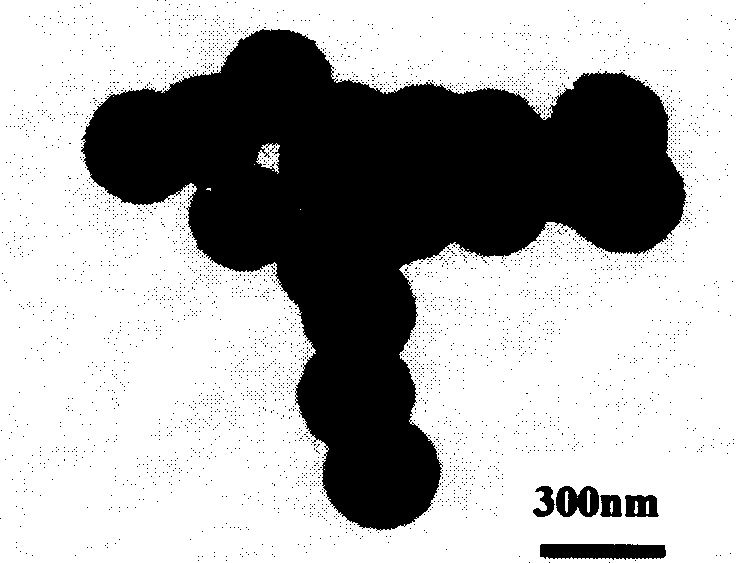

[0019] (1) Styrene, sodium lauryl sulfate, potassium persulfate and deionized water distilled under reduced pressure are mixed in a three-necked flask in a mass ratio of 100:0.1:1:574, nitrogen gas is passed for 20 minutes and the temperature is raised rapidly After stirring for 6 hours at 80°C, the emulsion was broken with sodium chloride solution, filtered and washed. The product was dried in a vacuum oven at room temperature for 24 hours, and the obtained powder was polystyrene microspheres with a diameter of about 375 nanometers.

[0020] (2) Mix 60 mg of polystyrene microspheres, 373.8 mg of cadmium chloride, 124.6 mg of thiourea and 50 g of water in a 50 mL Erlenmeyer flask, ultrasonicate for 5 minutes, then place in an oil bath to heat and stir at 80°C for 2 Hour. After the reaction is completed, it is washed with ethanol or water, centrifuged, and dried in an oven to obtain a powder which is the cadmium sulfide / polystyrene core-shell nanometer microsphere.

Embodiment 3

[0022] (1) Styrene, sodium lauryl sulfate, potassium persulfate and deionized water distilled under reduced pressure are mixed in a three-necked flask in a mass ratio of 100:0.5:1:574, nitrogen gas is passed for 20 minutes and the temperature is raised rapidly After stirring for 6 hours at 80°C, the emulsion was broken with sodium chloride solution, filtered and washed. The product was dried in a vacuum oven at room temperature for 24 hours, and the obtained powder was polystyrene microspheres with a diameter of about 130 nanometers.

[0023] (2) Mix 40 mg of polystyrene microspheres, 341.2 mg of cadmium sulfate, 111.3 mg of ammonium sulfide and 50 g of ethanol in a 50 mL Erlenmeyer flask, sonicate for 5 minutes, then heat and stir in an oil bath at 60°C for 4 hours. After the reaction is completed, it is washed with ethanol or water, centrifuged, and dried in an oven to obtain a powder which is the cadmium sulfide / polystyrene core-shell nanometer microsphere.

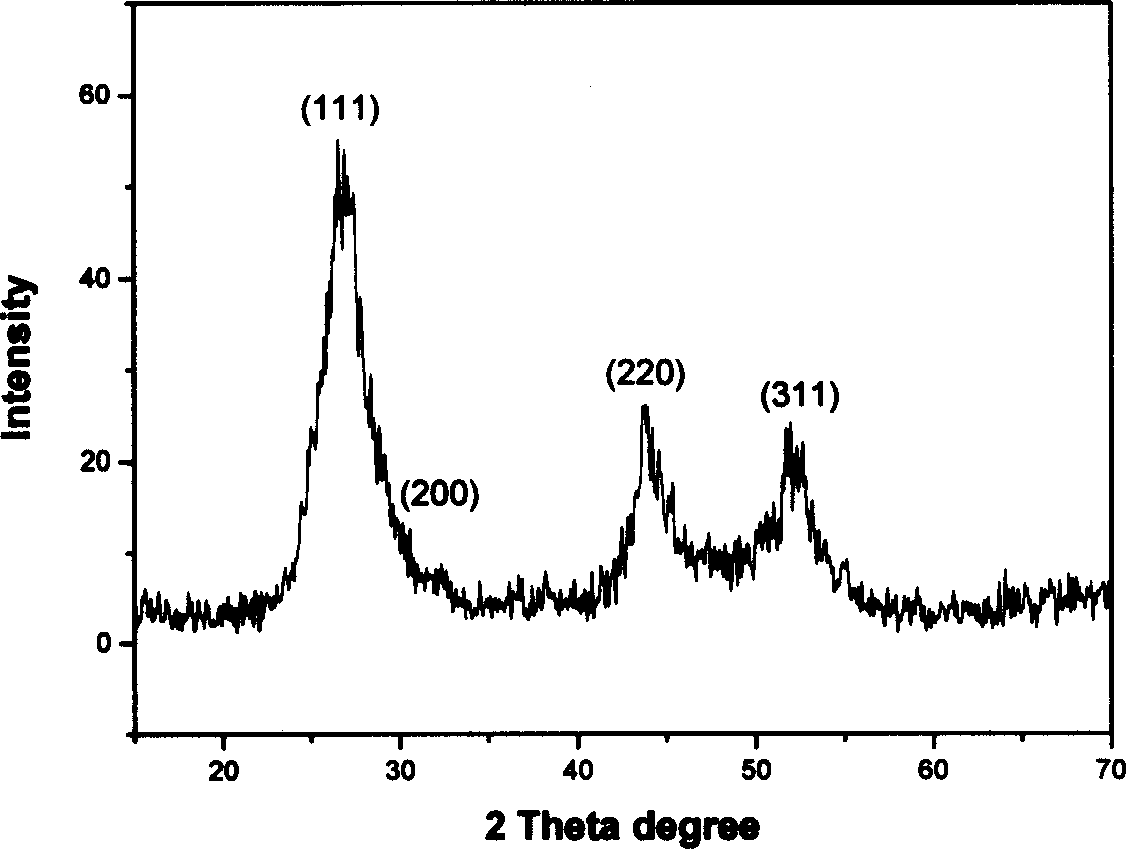

[0024] The X-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com