Barium titanate based electric resistor non-linear to voltage and its preparing process

A non-linear resistor, barium titanate technology, applied in the direction of varistor, varistor core, etc., can solve the problems of low capacitance of ring varistor, poor mechanical bending strength, complex sintering process, etc. The effect of reduced manufacturing cost, simplified production process, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

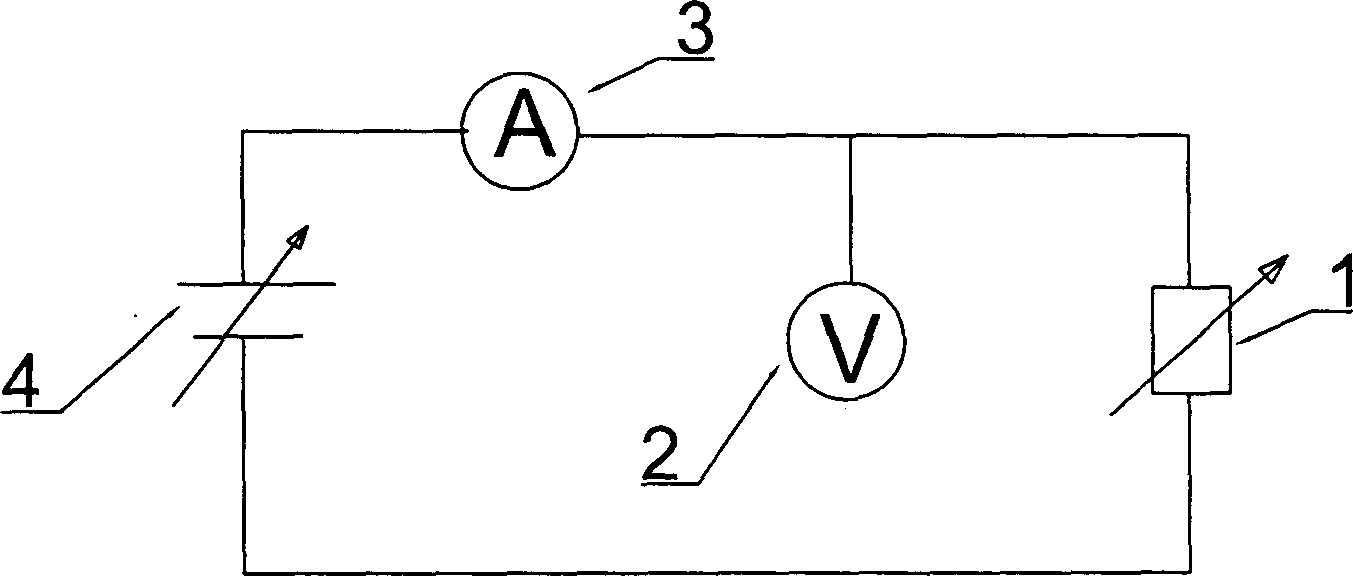

[0024] BaTiO produced by the commercially available oxalic acid method 3 as the principal component, the principal component expression (Ba 1-x Sr x ) m TiO 3 In x=0, and m=0.98, by adding TiO in proportion 2 Realize, with the main component being 100mol%, the addition amount of the first subcomponent, the second subcomponent and the third subcomponent are listed in Table 1, a total of 7 different formulas, each formula weighs the main component and three kinds of subcomponents in proportion Composition, according to the ratio of powder: agate ball: pure water=1: 1.5: 1.5, adopt ball mill to mix and grind for 12 hours, filter out slurry with 200 mesh sieve, add polyvinyl alcohol solution and mix evenly after slurry is baked and dried, pass Granulate with a 60-mesh sieve, the concentration of the polyvinyl alcohol solution is 10%, and the addition of the polyvinyl alcohol solution is 12% of the weight of the dried powder. The above-mentioned granulated powder is molded und...

Embodiment 2

[0035] The main component adopts solid-phase synthesis method to analyze pure BaCO 3 , SrCO 3 ,TiO 2 as the raw material, according to the expression (Ba 0.95 Sr 0.05 ) 0.98 TiO 3 Stoichiometric ratio and considering the purity of raw materials, weigh 1000 grams of the above three raw materials, add 1800 grams of pure water, 2000 grams of agate balls, put them in a 5-liter ball mill jar and mill them for 12 hours to form a slurry, which is baked and dried After passing through a 60-mesh sieve to obtain the mixed and ground raw meal, the raw meal was put into an alumina crucible and placed in a box-type electric furnace for solid-phase synthesis at 1250°C / 2 hours. After the synthesis, it was dry-milled and crushed, and passed through an 80-mesh sieve as the main component. The materials and addition amounts of the three subcomponents are the same as the sample number 101 in Example 1, and the subsequent production steps and test methods refer to Example 1; Table 3 lists th...

Embodiment 3

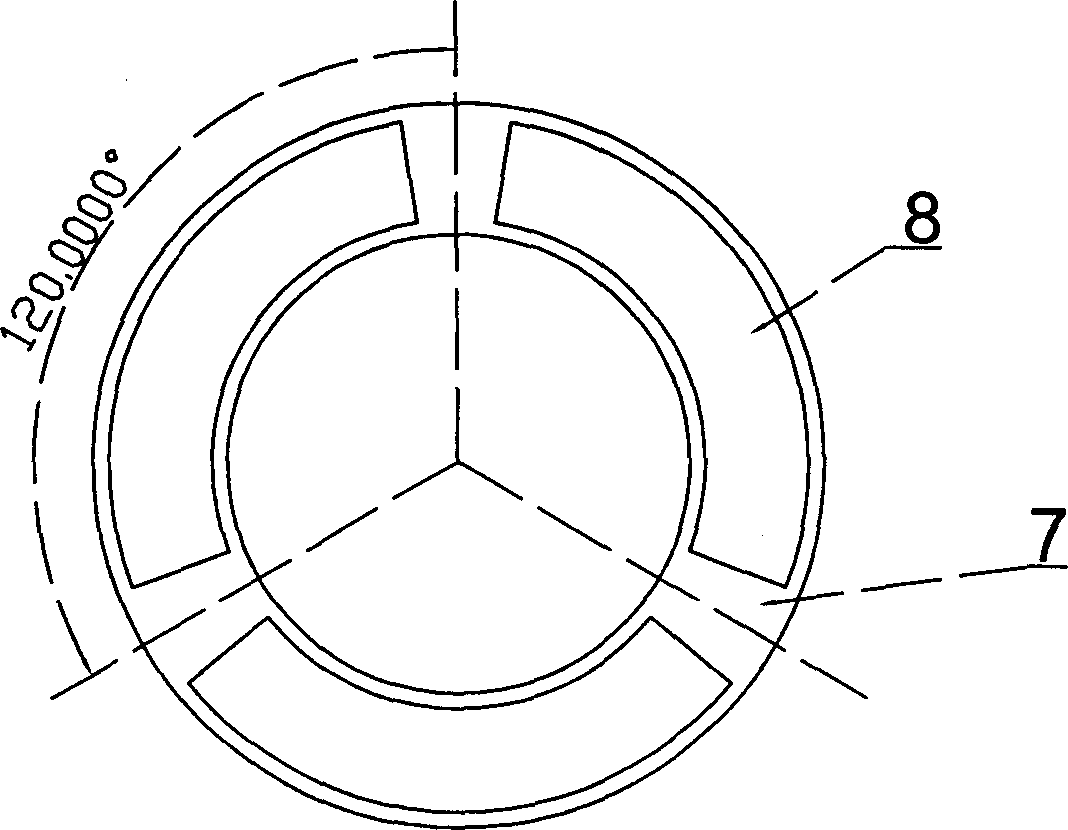

[0038] According to sample number in embodiment 1, be the component of 101 and the method described in embodiment 1 to make the circular preform sheet of external diameter 12.3mm, internal diameter 7.8mm, thickness 1mm; Comparative sample 108 adopts SrTiO 3 Main component, with the main component as 100mol%, add 2.0mol% TiO 2 , 1.0mol% Nb 2 o 5 , 0.5mol% MnO 2 , 0.5mol% SiO 2 According to the method described in Example 1, an annular preform sheet with an outer diameter of 12.3mm, an inner diameter of 7.8mm and a thickness of 1mm was produced. After the above two kinds of blanks are deglued, take half of them and use the method of Example 1 to carry out sintering and heat treatment, but the sintering temperature of comparative sample 108 is 1380 °C, and the heat treatment temperature is 1000 °C, while the sintering temperature of sample 101 is 1300 °C, and the heat treatment temperature is 1050°C; the other half of the two green sheets after debinding was sintered in a nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com