Process and equipment for preparing nm zinc oxide

A technology of nano-zinc oxide and production method, applied in chemical instruments and methods, zinc oxide/zinc hydroxide, zinc compounds, etc., can solve the problem that the particle size range and particle shape are difficult to effectively control, and it is difficult to realize thermodynamic quasi-static process. , can not guarantee the full completion of thermal decomposition and other problems, to achieve obvious economic and social benefits, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preparation of zinc sulfate can take low-grade zinc oxide or zinc ore as raw material, react with dilute sulfuric acid solution to make crude zinc sulfate solution, heat the solution to 80-90°C, add potassium permanganate to oxidize and remove iron, Manganese, then heated to 80°C, adding zinc powder, replacing copper and cadmium in the solution, and after the replacement, used potassium permanganate to oxidize and remove impurities for the second time at 80-90°C to obtain a refined zinc sulfate solution, which was prepared into 0.1 mol / L.

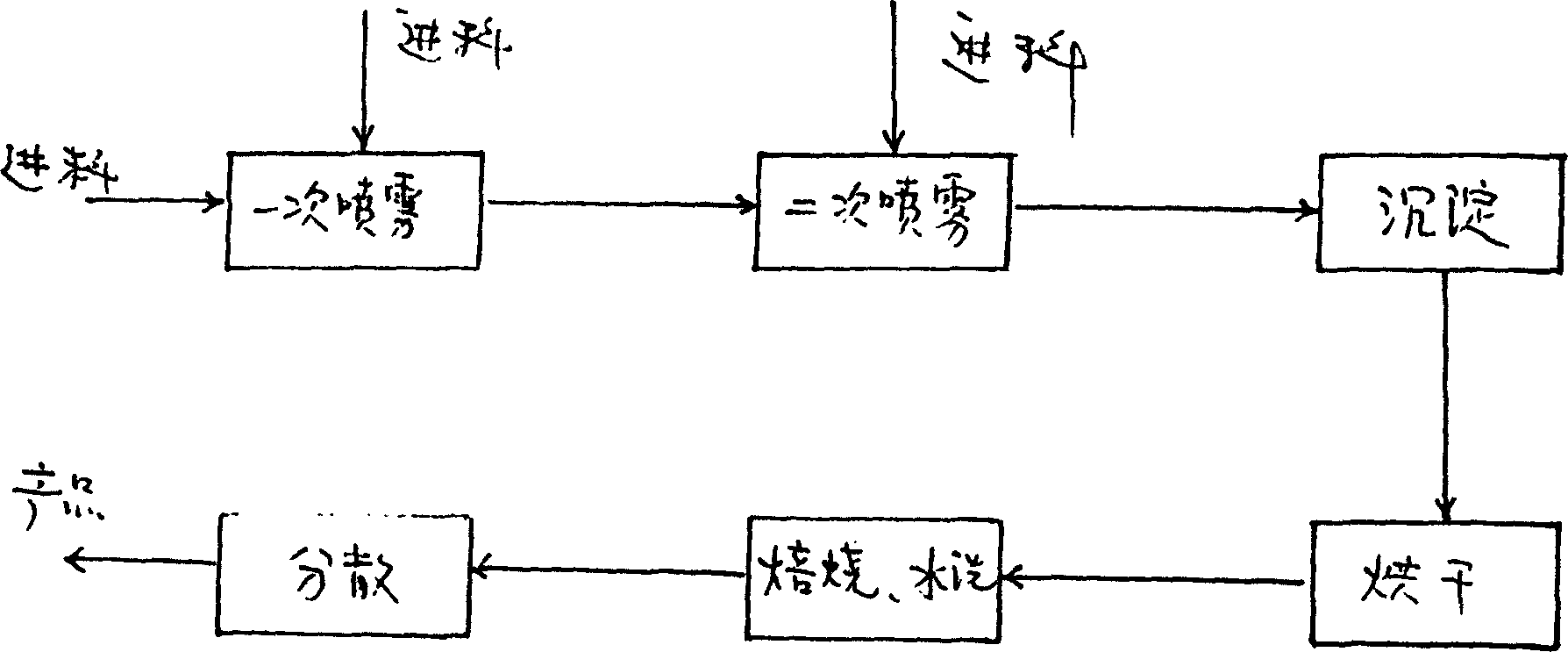

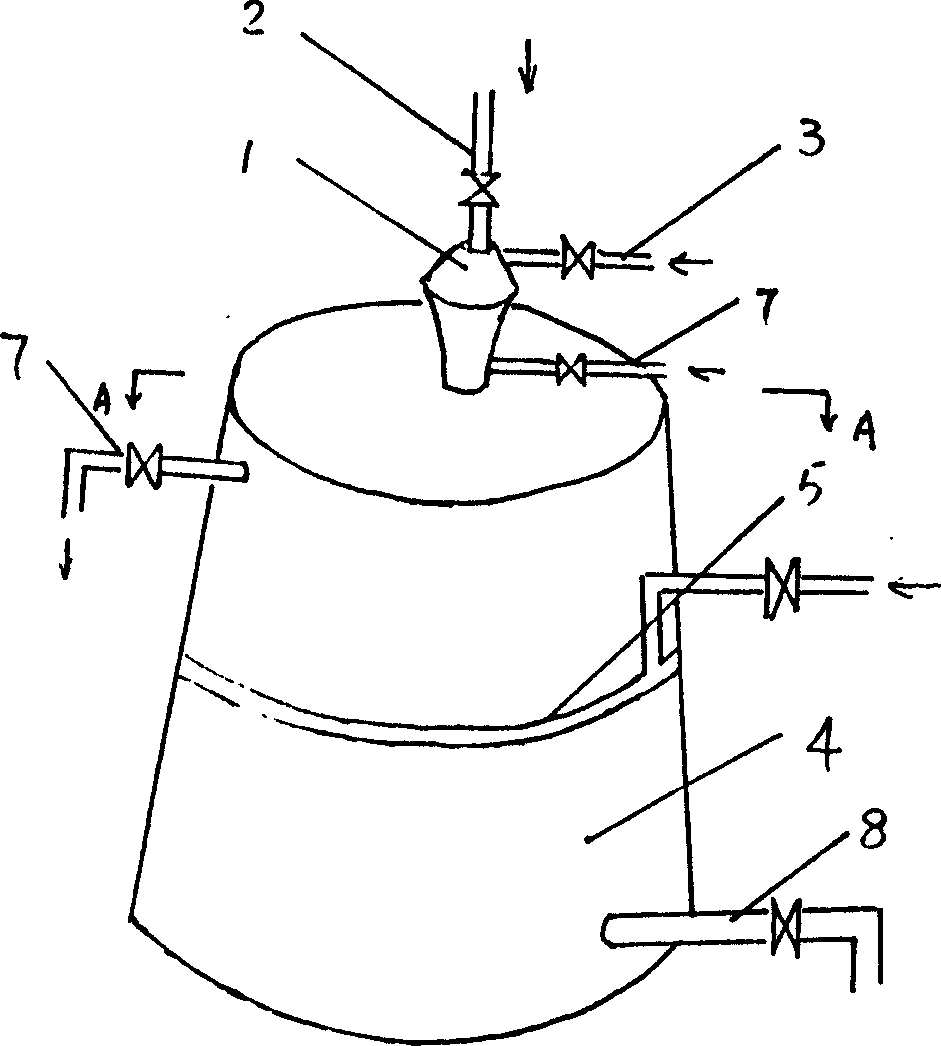

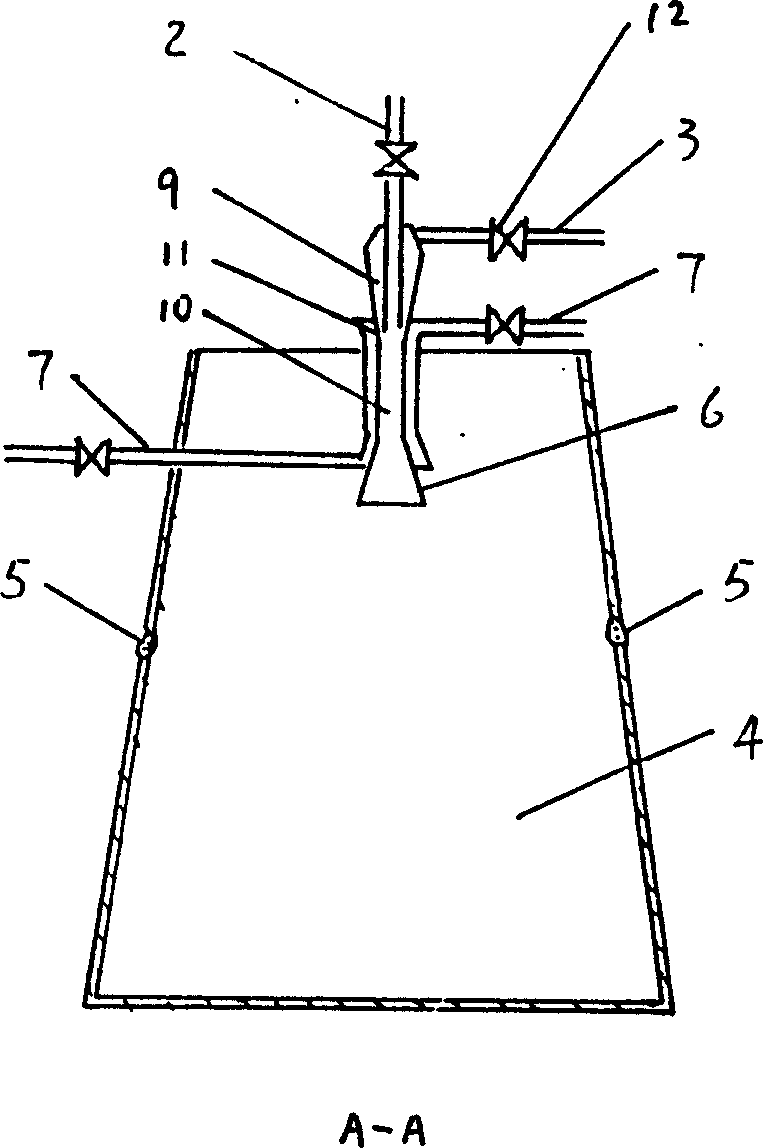

[0013] see figure 1 , the process flow is a two-stage spray synthesis method. The prepared zinc sulfate solution is heated at 80-90°C, connected to the feed pipe 2 of the nozzle 1, and sprayed into the nozzle 1 at a high speed under the condition of 0.4Mpa and placed at the entrance of the mixing chamber. Negative pressure is generated, so that the sodium hydroxide solution connected to the feeding pipe 3 is sucked into the mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com