Organogel, preparation method thereof and transparent optical device

An organic gel, refractive index technology, applied in the field of materials, can solve the problems of low refractive index, high elastic modulus, low yield rate, etc., and achieve the effect of high refractive index, low elastic modulus, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

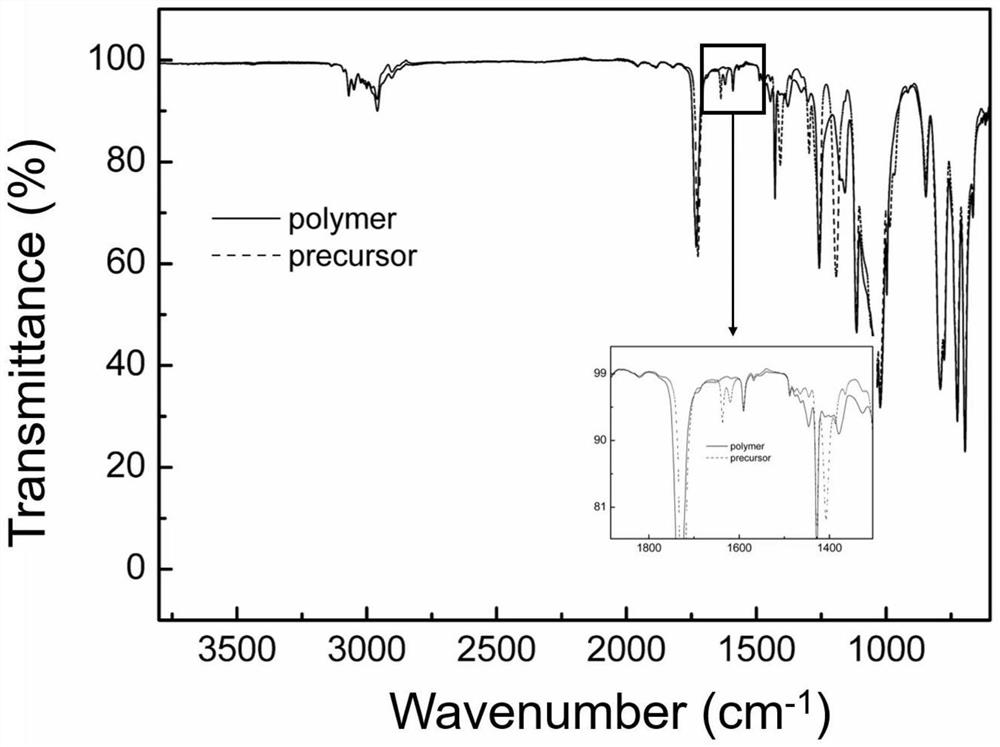

[0035] A preparation method of organogel, comprising:

[0036] mixing raw materials including acrylate polymer monomer, methylphenyl silicone oil with high refractive index, crosslinking agent and initiator, and reacting to obtain polymer precursor liquid;

[0037] The polymer precursor liquid is cured to obtain the organogel.

[0038] In an optional embodiment, the acrylate polymer monomer includes one of ethyl acrylate, butyl acrylate, methyl methacrylate, hydroxyethyl acrylate, benzyl acrylate, and hexafluorobutyl acrylate one or more.

[0039] In an optional embodiment, the refractive index of the high refractive index methylphenyl silicone oil ranges from 1.50 to 1.60.

[0040] In an optional embodiment, the crosslinking agent includes one or more of 1,6-hexanediol diacrylate, polyethylene glycol dimethacrylate, and polyethylene glycol diacrylate ;

[0041] In an optional embodiment, the amount of the crosslinking agent is 0.1%-1% of the molar amount of the acrylate p...

Embodiment 1

[0056] The present embodiment provides an organic gel, the monomer is selected from ethyl acrylate, the silicone oil is selected from polymethylphenylsiloxane (IOTA-704 from Aiyota Silicone Oil Co., Ltd.) with a room temperature refractive index of 1.5515, and the crosslinking agent is 1,6-Hexanediol diacrylate, the initiator is 1-hydroxycyclohexyl phenyl ketone, the volume ratio of monomer to silicone oil is 3:7, the dosage of crosslinking agent and initiator is ethyl acrylate respectively The molar percentage of the total amount is 0.2% and 1%.

[0057] Its preparation method is as follows:

[0058] (1) fully miscible acrylate polymer monomer, methylphenyl silicone oil with high refractive index, crosslinking agent and initiator to obtain transparent and uniform liquid;

[0059] (2) Crosslinking the homogeneous liquid obtained in step (1) to obtain the organogel; the crosslinking method adopts ultraviolet light with a wavelength of 365 nm to irradiate for 30 minutes.

[00...

Embodiment 2

[0064] This embodiment provides an organic gel, the monomer is hexafluorobutyl acrylate, and the silicone oil is polymethylphenylsiloxane (IOTA-705 from Iota Silicone Oil Co., Ltd.) with a room temperature refractive index of 1.5775, cross-linked The agent is polyethylene glycol dimethacrylate, the initiator is azobisisobutyronitrile, the volume ratio of monomer and silicone oil is 1:1, the dosage of crosslinking agent and initiator is hexafluorobutyl acrylate respectively The molar percentage of the total amount is 0.1% and 2%.

[0065] Its preparation method is as follows:

[0066] (1) fully miscible acrylate polymer monomer, methylphenyl silicone oil with high refractive index, crosslinking agent and initiator to obtain transparent and uniform liquid;

[0067] (2) Crosslinking the homogeneous liquid obtained in step (1) to obtain the organogel; the crosslinking method adopts heating at 60 degrees Celsius for 4 hours.

[0068] The light transmittance in the visible light r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com