Waterborne polyurethane modified epoxy resin as well as preparation method and application thereof

A water-based polyurethane and epoxy resin technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of low hydroxyl content, less cross-linking points, paint film flexibility, elongation at break and impact resistance Poor performance and other problems, to achieve the effect of high epoxy equivalent and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

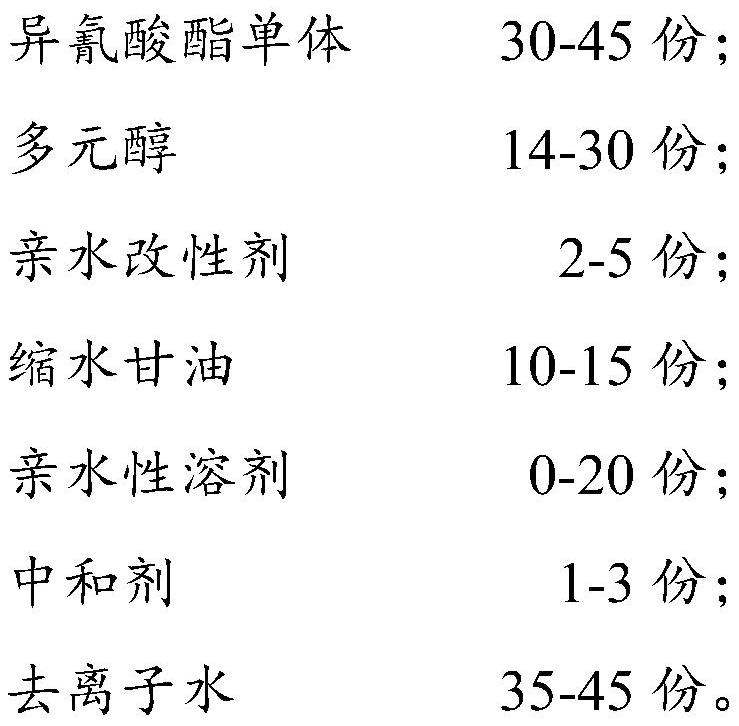

[0040] A water-based polyurethane modified epoxy resin is prepared by reacting the following raw materials:

[0041]

[0042]

[0043] A preparation method of water-based polyurethane modified epoxy resin, comprising the following steps:

[0044] (1) Add the isocyanate monomer TDI into the hydrophilic solvent acetone, heat up to 55°C for the first time, stir, and then add (the same amount each time) polyols (TMP, 1,4-butanediol and polyether polyol), the temperature was raised to 75°C for the second time, and the reaction was carried out to obtain an isocyanate prepolymer and then cooled to 55°C;

[0045] (2) adding hydrophilic modifier dimethylol propionic acid to the isocyanate prepolymer obtained in step (1), heating up to 75° C. for the third time, keeping the temperature for 4 hours, carrying out hydrophilic modification, and cooling to 65° C. ℃ add the neutralizing agent triethylamine to obtain the neutralized product;

[0046] (3) add glycidol in the neutralized...

Embodiment 2

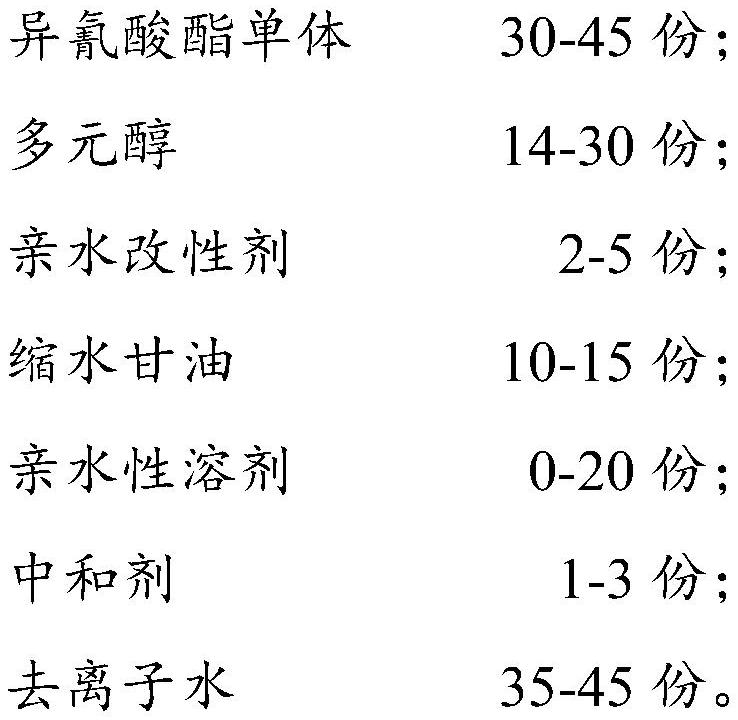

[0048] A water-based polyurethane modified epoxy resin is prepared by reacting the following raw materials:

[0049]

[0050]

[0051] A preparation method of water-based polyurethane modified epoxy resin, comprising the following steps:

[0052](1) Add the isocyanate monomer TDI into the hydrophilic solvent acetone, heat up to 65°C for the first time, stir, and then add (the same amount each time) polyols (TMP, neopentyl glycol, polyether) in three times polyol and polyester polyol), the temperature is raised to 85°C for the second time, and the reaction is carried out to obtain an isocyanate prepolymer and then the temperature is lowered to 65°C;

[0053] (2) adding hydrophilic modifier dimethylol butyric acid to the isocyanate prepolymer obtained in step (1), heating up to 85° C. for the third time, keeping the temperature for 2 hours, carrying out hydrophilic modification, and cooling to 65° C. ℃ add neutralizing agent triethylamine to obtain neutralized product;

...

Embodiment 3

[0056] A water-based polyurethane modified epoxy resin is prepared by reacting the following raw materials:

[0057]

[0058] A preparation method of water-based polyurethane modified epoxy resin, comprising the following steps:

[0059] (1) Heat the isocyanate monomer HDI to 60°C for the first time, stir, and then add (the same amount each time) polyols (TMP, 1,4-butanediol, polyether polyol and polyester in three additions) polyol), the temperature was raised to 80°C for the second time, and the reaction was carried out to obtain an isocyanate prepolymer and then cooled to 60°C;

[0060] (2) adding hydrophilic modifier dimethylol butyric acid to the isocyanate prepolymer obtained in step (1), heating up to 80° C. for the third time, keeping the temperature for 3 hours, carrying out hydrophilic modification, and cooling to 70° C. ℃ add neutralizing agent triethylamine to obtain neutralized product;

[0061] (3) adding glycidol in the neutralized product obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com