A kind of anti-tear leather shoe upper and preparation method thereof

A technology of anti-tearing and anti-tearing agent, which is applied in the direction of leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., and can solve the problem of napa shoes Low tear strength of finished upper leather, low firmness of finished shoe upper, poor tear resistance and other problems, to achieve the effect of improving tear resistance, improved tear resistance and strong cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

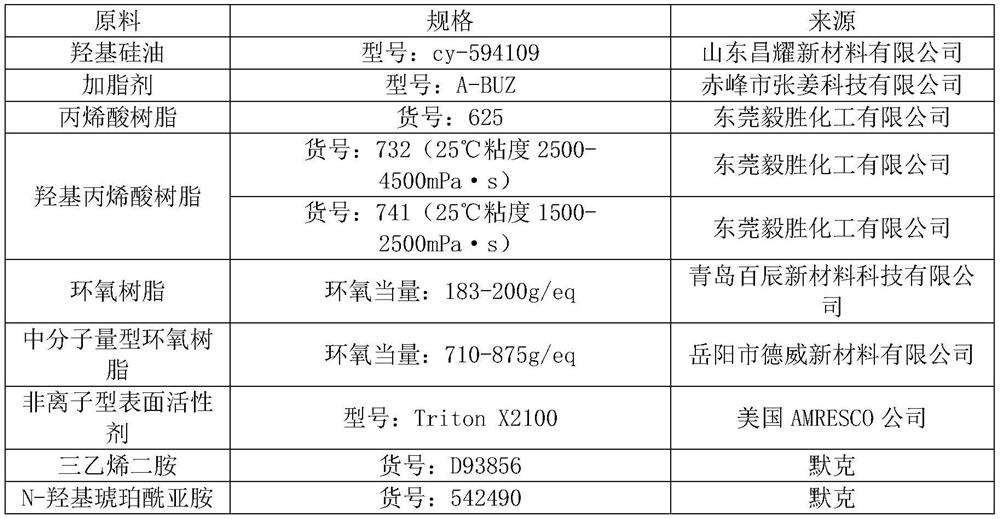

[0033] An anti-tear agent, the preparation method of which is as follows: heating 20g of acrylic resin, 5g of epoxy resin and 1g of crosslinking agent to 70°C, stirring evenly, and then adding 7g of hydroxy silicone oil, 1g of fatliquor, 3g of phosphate solution, 0.1g of surfactant and 0.05g of accelerator are mixed uniformly to prepare tear-resistant agent;

[0034] The epoxy equivalent of the epoxy resin used is 183-200g / eq; the type of fatliquor used is A-BUZ; the mass concentration of the phosphate solution used is 65wt% sodium phosphate solution; the type of surfactant used is Triton X2100 ; The accelerator used is triethylenediamine; The crosslinking agent used is N-hydroxysuccinimide.

preparation example 2-9

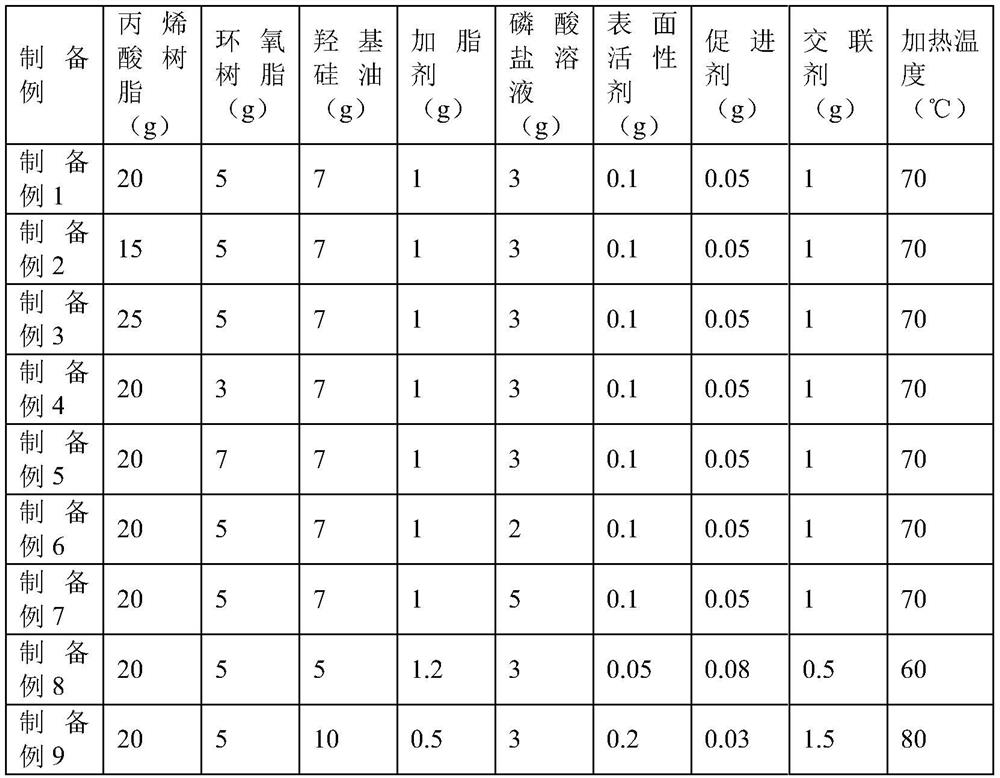

[0036] Preparation Examples 2-9 are all based on Preparation Example 1, and differ from Preparation Example 1 only in that the preparation conditions of the anti-tear agent are different, as shown in Table 2 for details.

preparation example 1-9

[0037] Table 2. Preparation conditions of preparation examples 1-9 anti-tear agents

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com