A kind of epoxy resin for matting powder coating and its preparation method and application

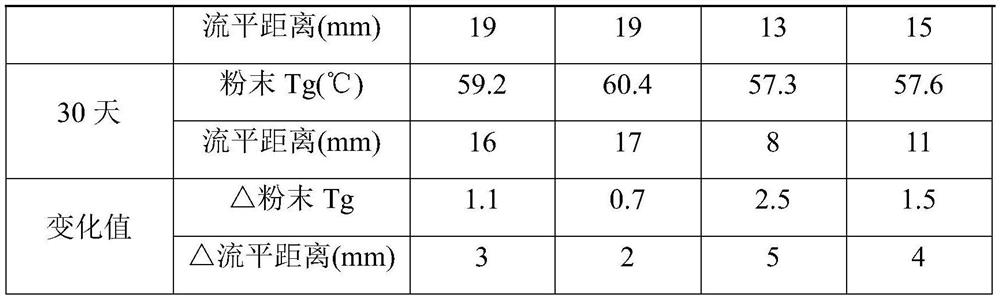

A matting powder coating and epoxy resin technology, applied in powder coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of matting powder coating matting effect and mechanical performance storage stability can not be satisfied at the same time, to improve storage Stability, gloss reduction, cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of epoxy resin for matting powder coating, comprising the following steps:

[0038] Step 1. Dissolution: Under the protection of nitrogen, mix 98g of epichlorohydrin and 200g of bisphenol A; heat up to 60°C to dissolve, and the dissolution time is 60min; add 180g of methyl isobutyl ketone, stir at a speed of 200r / min, and stir for 30min ;

[0039] Step 2, catalytic reaction: 310 g of sodium hydroxide solution with a concentration of 15% was added dropwise, the time of adding was 180 min, and the stirring speed was 200 r / min;

[0040] Step 3, separation and purification: including the following stages:

[0041] Separation section: Add 200g of methyl isobutyl ketone and 100g of water, stir at 85°C for 30min at a stirring speed of 100r / min, remove the lower aqueous solution after stirring;

[0042] Neutralization section: add 60g of water and 70g of neutralizing agent with a concentration of 15%, stir at 85°C for 30min at a stirring speed of 100r / min...

Embodiment 2

[0046] A preparation method of epoxy resin for matting powder coating, comprising the following steps:

[0047] Step 1. Dissolving: under the protection of nitrogen, mix 106g of epichlorohydrin and 200g of bisphenol A; heat up to 60°C to dissolve, and the dissolution time is 60min; add 160g of xylene, stir at a speed of 300r / min, and stir for 30min;

[0048] Step 2, catalytic reaction: adding 305g of sodium hydroxide solution with a concentration of 15% dropwise for 180min, and the stirring speed is 300r / min;

[0049] Step 3, separation and purification: including the following stages:

[0050] Liquid separation section: Add 200g of xylene and 100g of water, stir at 85°C for 30min, the stirring speed is 120r / min, after the stirring is completed, remove the lower aqueous solution;

[0051] Neutralization section: add 60g of water and 70g of neutralizing agent with a concentration of 15%, stir at 85°C for 30min at a stirring speed of 120r / min, and remove the lower aqueous solut...

Embodiment 3

[0055] A preparation method of epoxy resin for matting powder coating, comprising the following steps:

[0056] Step 1. Dissolving: under the protection of nitrogen, mix 103g of epichlorohydrin and 200g of bisphenol A; heat up to 55°C to dissolve, and the dissolution time is 60min; add 160g of toluene, stir at a speed of 250r / min, and stir for 30min;

[0057] Step 2, catalytic reaction: dripping concentration is 225g of potassium hydroxide solution of 20%, dripping time is 240min, and stirring speed is 250r / min;

[0058] Step 3, separation and purification: including the following stages:

[0059] Separation section: Add 200g of toluene and 100g of water, stir at 90°C for 30min at a stirring speed of 100r / min, remove the lower aqueous solution after stirring;

[0060] Neutralization section: add 60g of water and 70g of neutralizing agent with a concentration of 15%, stir at 80°C for 30min, and the stirring speed is 100r / min, and remove the lower aqueous solution;

[0061] Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com