Flexible mildew-proof waterproof putty powder and preparation process thereof

A water-resistant putty and putty powder technology, which is applied in the direction of filling slurry, etc., can solve the problems of increasing the sticking time of putty with the wall, the decrease of waterproof and mildew resistance, and the inability to meet the simple construction, so as to achieve good mechanical properties of the cured product, Good anti-mildew and anti-bacterial performance, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

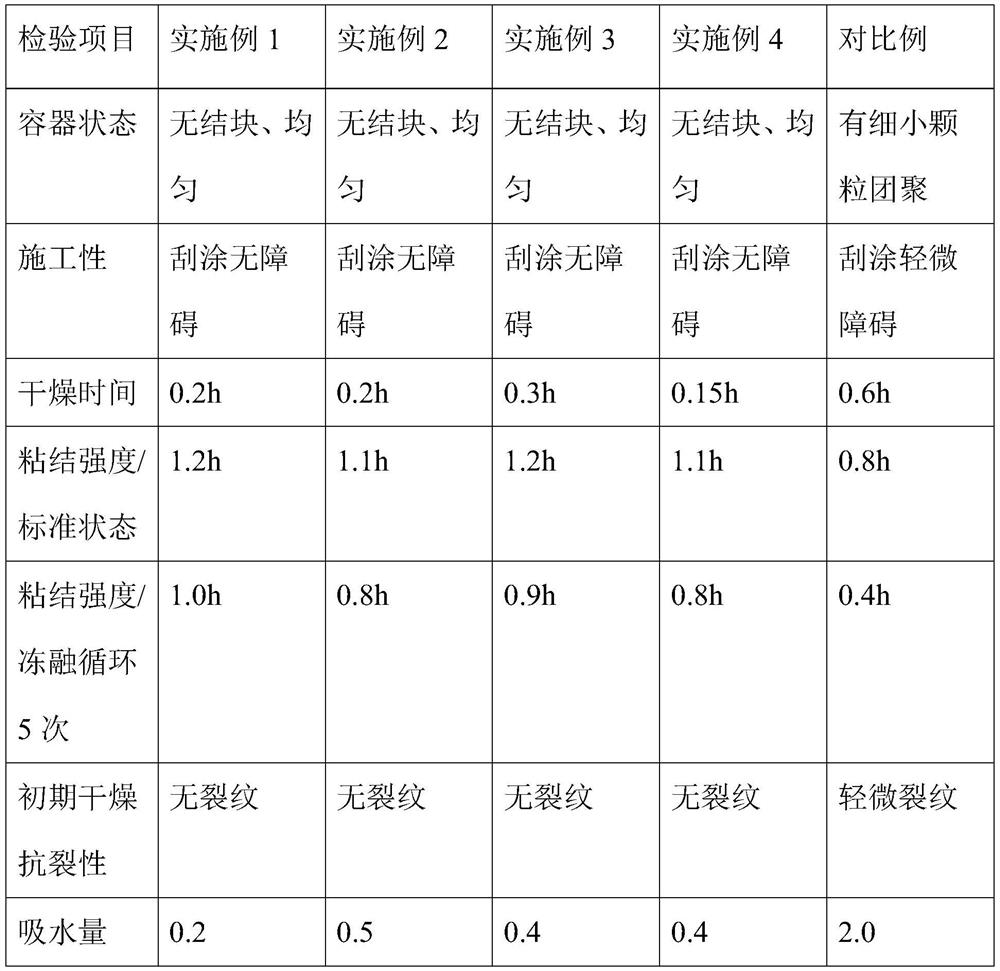

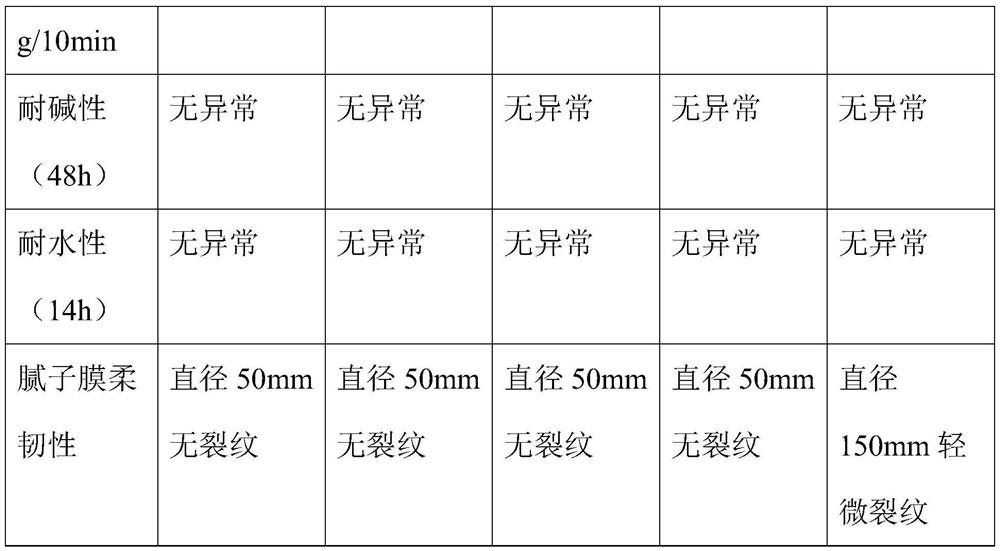

Examples

Embodiment 1

[0031] A flexible anti-mildew and water-resistant putty powder, based on a total of 100 parts, including 22.42 parts of heavy calcium powder, 33.64 parts of ash calcium powder, 13.45 parts of gypsum, 4.48 parts of epoxy resin, 13.85 parts of ordinary talcum powder, and low oil absorption talc 4.15 parts of flour, 2.43 parts of clay, 0.12 parts of sodium percarbonate, 0.05 parts of hydrogen peroxide, 1.00 parts of rubber powder, 0.28 parts of starch, 0.06 parts of bamboo fiber, 0.85 parts of lignocellulose, 2.82 parts of hydroxypropyl cellulose, and 0.05 parts of calcium sulfate , 0.05 parts of calcium chloride, 0.10 parts of activated alumina, 0.12 parts of diatom mud antifungal agent BJ-78, 0.06 parts of antifungal agent BJ-75, and 0.02 parts of dry film antifungal agent BJ-76;

[0032] Wherein what adopted in the epoxy resin is 2.24 parts of glycidyl ester epoxy resins and 2.24 parts of aliphatic epoxy resins.

[0033] The preparation process of this kind of flexible anti-mi...

Embodiment 2

[0043] A flexible anti-mildew and water-resistant putty powder, based on a total of 100 parts, including 25.81 parts of heavy calcium powder, 25.81 parts of ash calcium powder, 25.80 parts of gypsum, 2.58 parts of epoxy resin, 12.00 parts of ordinary talcum powder, and talc with low oil absorption 3.00 parts of powder, 1.01 parts of clay, 1.01 parts of clay, 0.20 parts of sodium percarbonate, 0.08 parts of hydrogen peroxide, 0.50 parts of rubber powder, 0.15 parts of starch, 0.04 parts of bamboo fiber, 0.22 parts of lignocellulose, 1.19 parts of hydroxypropyl cellulose, 0.08 parts of calcium sulfate, 0.12 parts of calcium chloride, 0.20 parts of activated alumina, 0.05 parts of powdered sodium hexametaphosphate, 0.10 parts of diatom mud antifungal agent BJ-78, and 0.05 parts of dry film antifungal agent BJ-76 ;

[0044] Wherein what adopted in the epoxy resin is 2.40 parts of glyceride epoxy resin and 0.28 part of glycidyl amine epoxy resin.

[0045] The preparation process o...

Embodiment 3

[0047] A flexible anti-mildew and water-resistant putty powder, based on a total of 100 parts, including 18.41 parts of heavy calcium powder, 46.02 parts of ash calcium powder, 11.05 parts of gypsum, 5.52 parts of epoxy resin, 8.74 parts of ordinary talcum powder, and talc with low oil absorption 3.06 parts of powder, 0.61 parts of clay, 1.42 parts of clay, 0.41 parts of sodium percarbonate, 0.06 parts of hydrogen peroxide, 0.90 parts of rubber powder, 0.27 parts of starch, 0.13 parts of bamboo fiber, 0.82 parts of lignocellulose, 2.18 parts of hydroxypropyl cellulose, 0.02 parts of calcium sulfate, 0.03 parts of calcium chloride, 0.05 parts of activated alumina, 0.07 parts of powdered sodium hexametaphosphate, 0.15 parts of diatom mud antifungal agent BJ-78, and 0.08 parts of dry film antifungal agent BJ-76 ;

[0048] Wherein what adopted in the epoxy resin is 5.52 parts of glyceride epoxy resins.

[0049] The preparation process of this kind of flexible mildew-proof and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com