High-activity flux-cored brazing filler metal capable of improving brazing strength of heterogeneous materials and preparation method of high-activity flux-cored brazing filler metal

A heterogeneous material, high activity technology, used in welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve the problems of low connection strength and weak activity of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present embodiment also provides a preparation method of flux-cored solder, comprising the following steps:

[0042] S11: smelting to obtain a brazing filler metal alloy according to the metal ratio of the sheath, and rolling the brazing filler metal alloy into a sheet-like brazing filler metal sheath;

[0043] S12: wrap the sheet brazing filler metal on the surface of the flux core to obtain a composite flux core;

[0044] S13: Drawing the composite flux core to obtain flux cored solder.

[0045] In this embodiment, the preparation of the flux-cored solder can also be obtained by first rolling the outer skin of the sheet-like solder into a desired shape, and then filling the flux core inside. This method is simple to operate and suitable for large-scale production.

[0046] Further, the smelting step of the solder alloy includes:

[0047] S21: put silver, copper, germanium and / or silicon and / or active elements into the crucible, conduct induction heating, and ad...

Embodiment 1

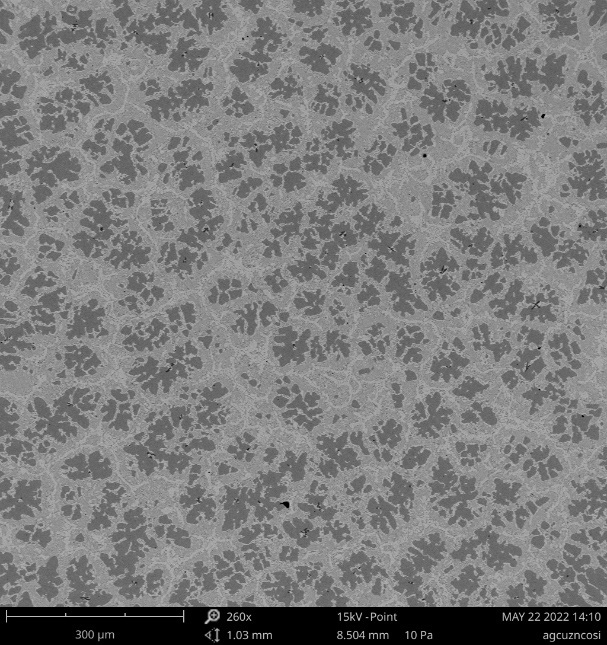

[0058] This embodiment provides a high-activity solder for improving the brazing strength of dissimilar materials, including: 50 parts by mass of silver; 25 parts by mass of copper; 22.1 parts by mass of zinc; 2.5 parts by mass of cobalt; 0.2 parts by mass of germanium; and 0.2 parts by mass of active metal titanium parts by mass.

[0059] Use the brazing filler metal provided in this example to braze 45# steel / YG6X, and measure the shear strength of the joint. The shear strength of the joint is shown in Table 1.

Embodiment 2

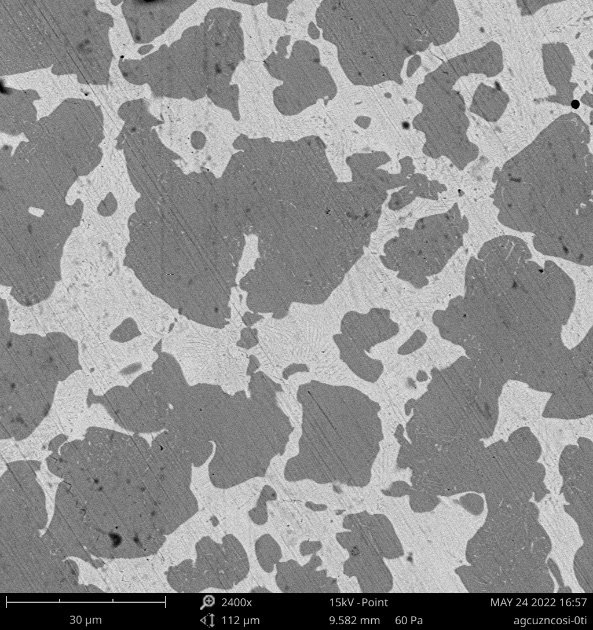

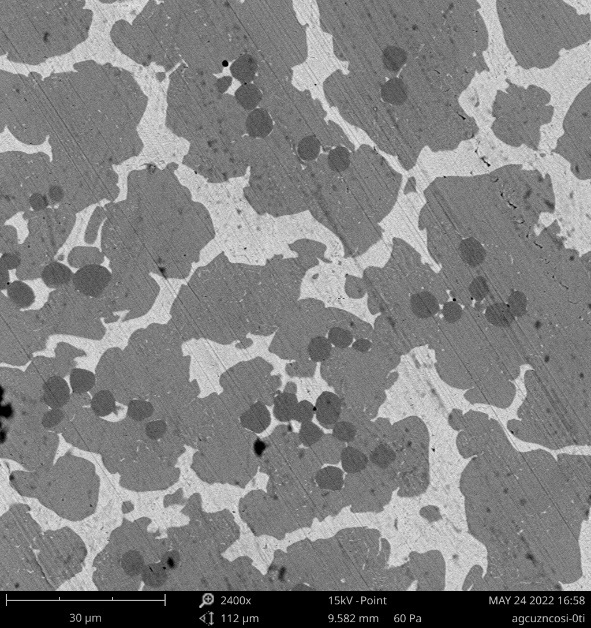

[0061] This embodiment provides a highly active solder for improving the brazing strength of dissimilar materials, including: 30 parts by mass of silver; 44 parts by mass of copper; 23.5 parts by mass of zinc; 1.5 parts by mass of cobalt; 0.7 parts by mass of silicon; and 0.3 parts by mass of active metal chromium parts by mass. The electron microscope image of the microstructure of the solder is as follows figure 2 shown.

[0062] Use the brazing filler metal provided in this example to braze 45# steel / YG6X, and measure the shear strength of the joint. The shear strength of the joint is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com