Platinum film with oversized crystal grains and preparation method thereof

A thin-film preparation and thin-film technology, applied in the field of ultra-large grain platinum thin film and its preparation, can solve the problems of low grain boundary density, reduce material cost, increase the thickness of platinum thin film, etc., achieve less structural defects, simple heat treatment method, thin film The effect of layer densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A method for preparing a platinum thin film, comprising the following steps:

[0049] S1, depositing one or more layers of oxygen-containing platinum films on an alumina substrate;

[0050] S2, heat-treating the oxygen-containing platinum thin film.

[0051] Another platinum thin film preparation method, comprising the following steps:

[0052] S1, deposit a layer of oxygen-containing platinum film on the alumina substrate;

[0053] S2, heat treating the above-mentioned oxygen-containing platinum film;

[0054] S3, depositing one or more layers of oxygen-containing platinum films on the oxygen-containing platinum films after the above heat treatment;

[0055] S4, heat-treating the above-mentioned oxygen-containing platinum film;

[0056] The steps S3 and S4 can be repeated.

[0057] A preferred example, the heat treatment temperature is 0.52T m ~ 0.72T m , T m is the melting point of metal platinum, and the heat treatment atmosphere is any of air, argon, and nitr...

Embodiment 1

[0060] The present embodiment provides a method for preparing a platinum thin film with super large grains, comprising the following steps:

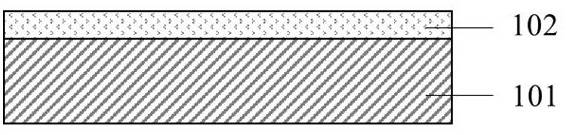

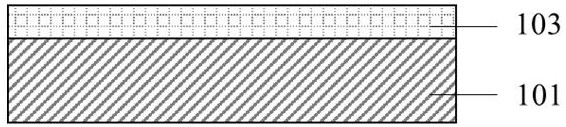

[0061] S1, providing a ceramic substrate 101, and depositing a layer of oxygen-containing platinum film 102 on the ceramic substrate;

[0062] S2, heat-treating the oxygen-containing platinum film 102 to obtain a platinum film 103 with super-large crystal grains.

[0063] In step S1, the oxygen-containing platinum thin film 102 is prepared by a magnetron sputtering method, and the sputtering carrier gas is a mixed gas of argon and oxygen, wherein the volume fraction of oxygen is 0%-10%.

[0064] In step S2, the heat treatment atmosphere is air, and the heat treatment temperature is 800°C to 1100°C.

Embodiment 2

[0066] The present embodiment provides a method for preparing a platinum thin film with super large grains: comprising the following steps:

[0067] S1, providing a ceramic substrate 201, and depositing a layer of oxygen-containing platinum film 202 on the ceramic substrate;

[0068] S2, performing heat treatment on the oxygen-containing platinum film 202 to obtain a film 203 after the heat treatment of 202;

[0069] S3, depositing a layer of oxygen-containing platinum film 204 on the heat-treated film 203;

[0070] S4, heat treatment on the above-mentioned thin films 203 and 204 to obtain a platinum thin film 205 with super-large crystal grains.

[0071] In step S1, the oxygen-containing platinum film 202 is prepared by a magnetron sputtering method, and the sputtering carrier gas is a mixed gas of argon and oxygen, wherein the volume fraction of oxygen is 30%-50%.

[0072] In step S2, the heat treatment temperature is 900°C to 1100°C, and the heat treatment atmosphere is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com