Hard alloy/metal ceramic powder for 3D printing and preparation method thereof

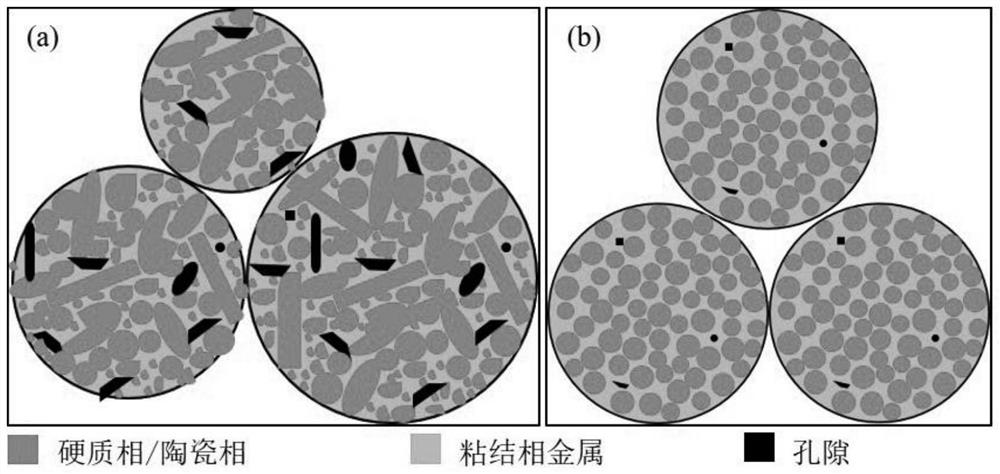

A cemented carbide and cermet technology, applied in metal processing equipment, nanotechnology for materials and surface science, transportation and packaging, etc., can solve the problem of limited dissolution and re-precipitation of hard phase/ceramic phase grains, and inability to Complete the problems of sufficient liquid phase flow, particle rearrangement, and uneven dispersion of components to achieve the effects of avoiding component segregation, good flow performance and filling performance, and performance tending to be consistent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of cemented carbide / cermet powder for 3D printing, comprising the following steps:

[0040] In step S1, the hard phase / ceramic phase raw material powder and the binder phase metal raw material powder are respectively deagglomerated, crushed and classified by using the air pulverization and classification technology, so as to obtain the hard phase / ceramic phase powder and the adhesive phase powder with uniform and narrow particle size distribution. junction metal powder;

[0041] Specifically, the hard phase / ceramic phase powder is tungsten carbide, molybdenum carbide, titanium carbide, titanium nitride, titanium carbonitride, tantalum carbide, niobium carbide, silicon carbide, titanium boride, boron carbide, rhenium boride, oxide At least one of aluminum, zirconia, and magnesium oxide; the binder phase metal raw material powder is at least one of metal Co, Ni, Fe, Mn, Cu, Zn, Al, Sn, Cr, W, Mo;

Embodiment 1

[0064] A WC-10wt.%Co cemented carbide powder for 3D printing, the preparation method comprising the following steps:

[0065] In step S1, the jet-type single-stage jet mill is used to depolymerize and classify 500Kg of WC with an average particle size of 5 μm to obtain ultra-fine WC with an average particle size of 0.4 μm. The main working parameter of the jet-type single-stage jet mill is the feeding speed. 50Kg / h, the working pressure of the jet mill is 15MPa, and the wind pressure of the cyclone collector is 10KPa;

[0066] Step S2, adding 90Kg of ultra-fine WC with an average particle size of 0.4 μm, 10Kg of Co powder with an average particle size of 1 μm and 3Kg of carboxymethyl cellulose into 150 L of water, fully stirring and dispersing to form a gel suspension;

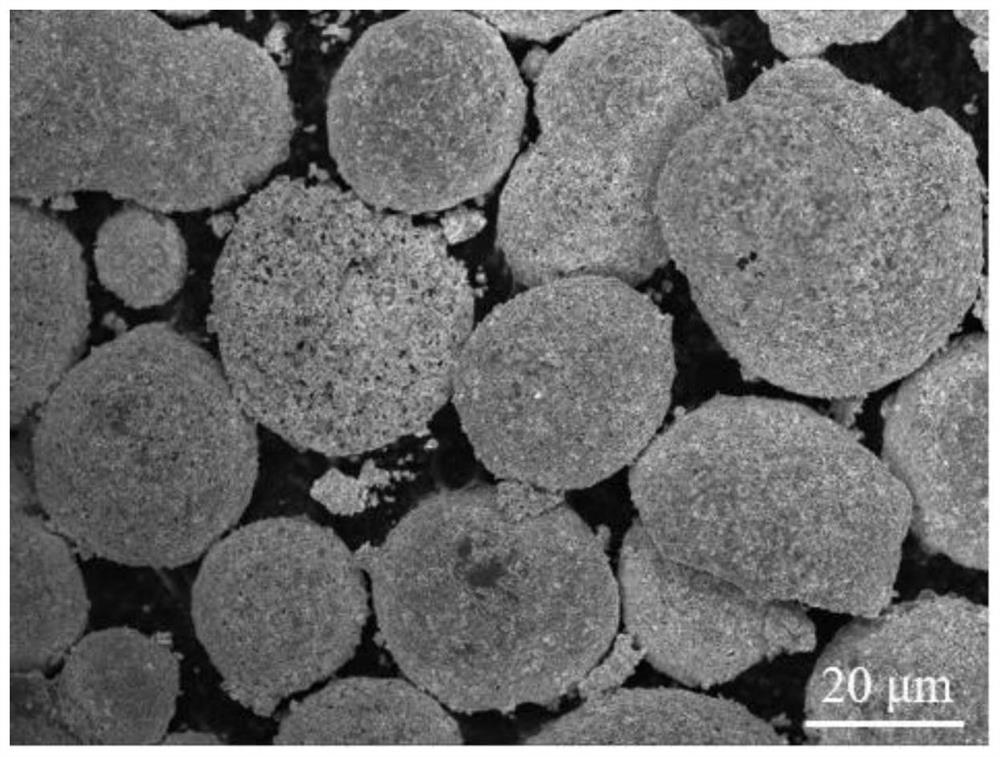

[0067] Step S3, spray-drying the gel suspension at 100° C. in a nitrogen atmosphere to obtain a porous spherical powder; the SEM image of the porous spherical powder is shown in figure 2 ;

[0068] Step S4,...

Embodiment 2

[0073] A TiB for 3D printing 2 -10wt.%Co-10wt.%Ni cermet powder, its preparation method includes the following steps:

[0074] In step S1, 200Kg of TiB with an average particle size of 2 μm is processed by a counter-jet single-stage jet mill. 2 Deagglomeration and classification were performed to obtain ultrafine TiB with an average particle size of 0.5 μm 2 , the main working parameters of the jet single-stage jet mill are the feeding speed 30Kg / h, the working pressure of the jet mill 20MPa, and the wind pressure of the cyclone collector 4KPa;

[0075] Step S2, 80Kg of ultrafine TiB with an average particle size of 0.5 μm 2, 10Kg of Co powder with an average particle size of 1μm, 10Kg of Ni powder with an average particle size of 1μm and 5Kg of polyvinylpyrrolidone were added to 200L of absolute ethanol, fully stirred and dispersed to form a gel suspension;

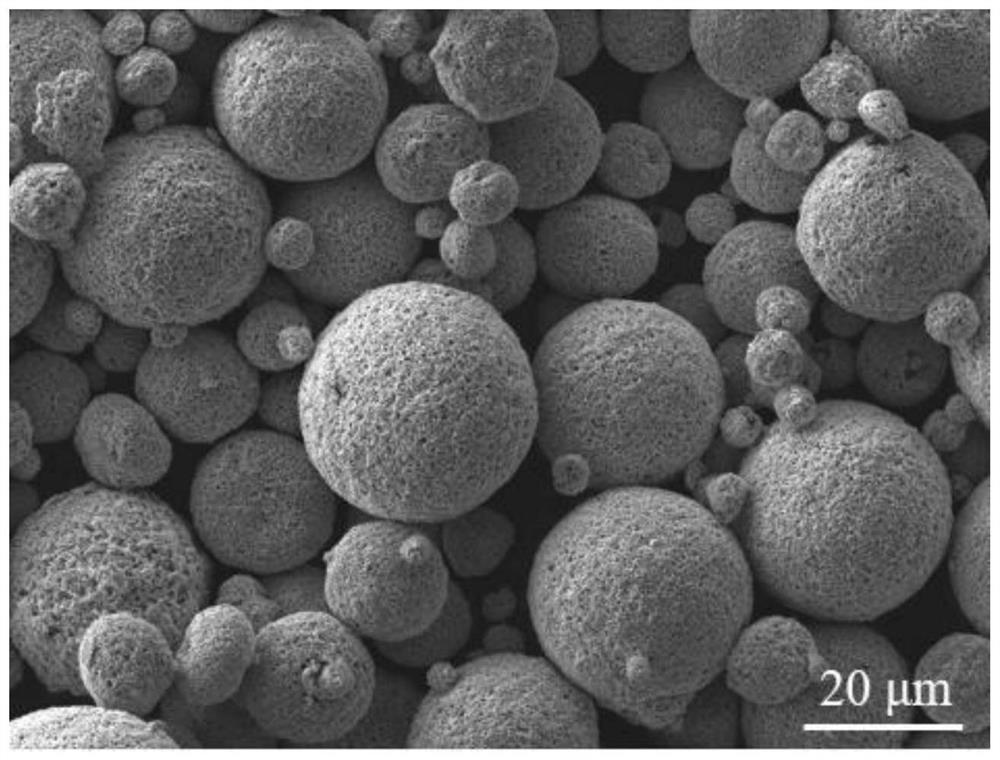

[0076] Step S3, spray-drying the gel suspension at 80°C in an argon atmosphere to obtain a porous spherical powder;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com