High-entropy zirconia thermal barrier coating material with stable high-temperature phase and preparation method of high-entropy zirconia thermal barrier coating material

A technology of thermal barrier coating and zirconia, which is applied in the field of coating materials, can solve problems such as high fracture toughness, coating cracking and failure, and achieve the effect of high fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

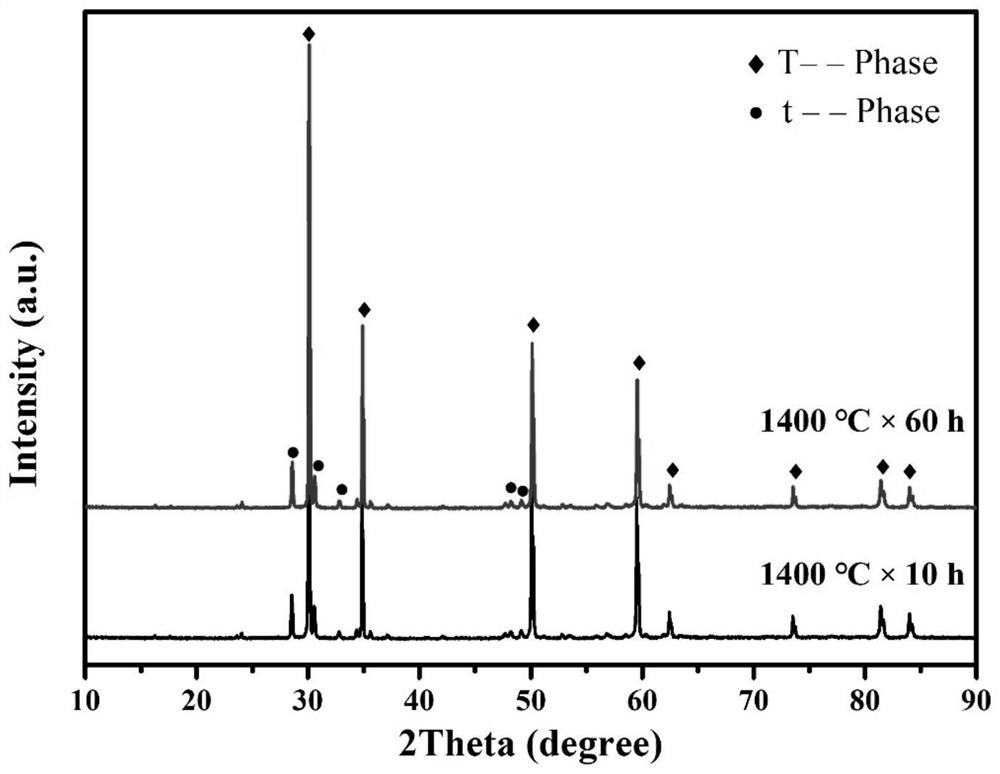

Embodiment 1

[0027] Weigh 6.396gHfCl 4 Dissolve with absolute ethanol, 6.445g ZrOCl 2 ·8H 2 O, 7.164g TaCl 5 Dissolve and mix with deionized water respectively to form solution A, 2.258gY 2 O 3 , 3.941gYb 2 O 3 Heating and dissolving with nitric acid and mixing them into solution B respectively, mixing solutions A and B into solution C, adding the mixed solution C dropwise to the ammonia solution (pH≥10) and stirring continuously to ensure that the system pH≥10 in the process of co-precipitation, Until the solution C is all dripped, let stand for 18 hours until the white precipitate is completely deposited at the bottom of the container; the precipitate is first centrifuged with deionized water for 6 times, and then centrifuged with absolute ethanol for 1 time, until the pH of the supernatant is close to 7 and drops. The centrifugation rate was 6000 r / min until no white precipitate was produced by adding the silver nitrate solution; the washed precipitate was dried in a drying oven, ...

Embodiment 2

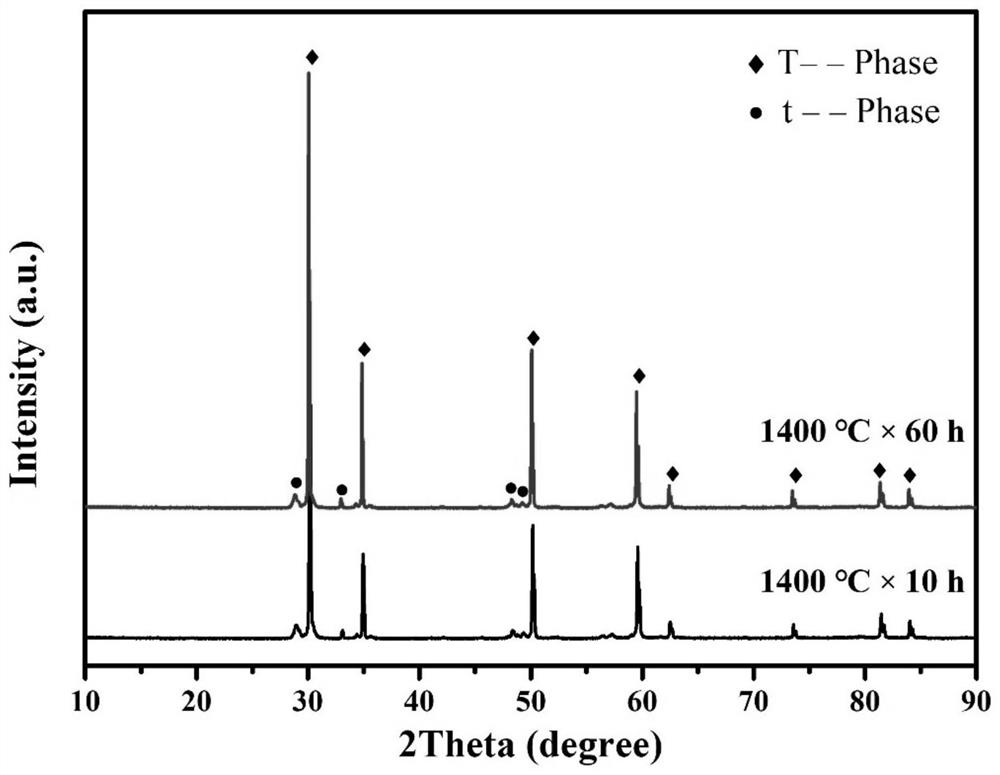

[0031] Weigh 6.396gHfCl 4 Dissolve with absolute ethanol, 6.445g ZrOCl 2 ·8H 2 O, 5.403gNbCl 5 Dissolve and mix with deionized water respectively to form solution A, 2.258gY 2 O 3 , 3.941gYb 2 O 3 Heating and dissolving with nitric acid and mixing them into solution B respectively, mixing solutions A and B into solution C, adding the mixed solution C dropwise to the ammonia solution (pH≥10) and stirring continuously to ensure that the system pH≥10 in the process of co-precipitation, Until the solution C is all dripped, let stand for 18h until the white precipitate is completely deposited on the bottom of the container; the precipitate is first centrifuged with deionized water for 6 times, and then centrifuged with absolute ethanol for 1 time, until the supernatant pH=7 and dripping The centrifugation rate was 6000 r / min until no white precipitate was produced by adding the silver nitrate solution; the washed precipitate was dried in a drying oven, ground in a mortar and ...

Embodiment 3

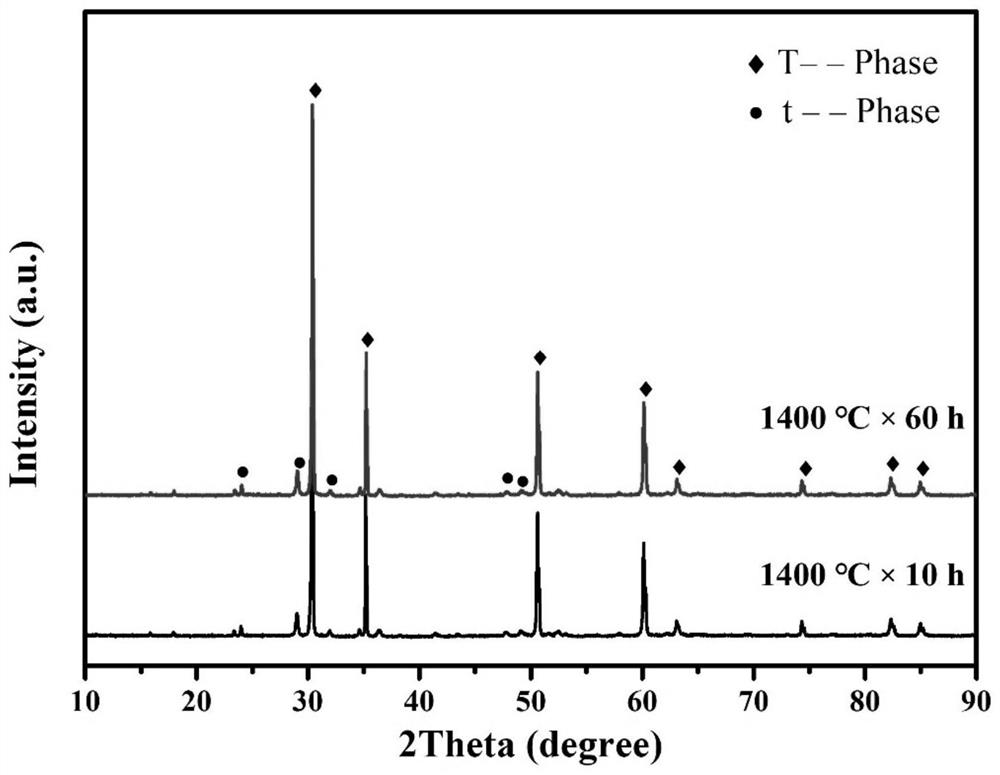

[0035] Weigh 6.396gHfCl 4 Dissolve with absolute ethanol, 6.445g ZrOCl 2 ·8H 2 O, 7.164g TaCl 5 Dissolve and mix with deionized water respectively to form solution A, 2.258gY 2 O 3 , 1.379gSc 2 O 3 Heating and dissolving with nitric acid and mixing them into solution B respectively, mixing solutions A and B into solution C, adding the mixed solution C dropwise to the ammonia solution (pH≥10) and stirring continuously to ensure that the system pH≥10 during the co-precipitation process , until the solution C is all dripped, and let stand for 18h until the white precipitate is completely deposited at the bottom of the container; the precipitate is first centrifuged with deionized water for 6 times, and then centrifuged with absolute ethanol for 1 time, until the supernatant pH=7 and The centrifugation rate was 6000 r / min until the silver nitrate solution was added dropwise and no white precipitate was produced; the washed precipitate was dried in a drying oven, ground with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness value | aaaaa | aaaaa |

| Fracture toughness value | aaaaa | aaaaa |

| Fracture toughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com