Water-based fluorinated acrylate copolymer emulsion and preparation method thereof

A technology of acrylate and hydroxypropyl acrylate, which is applied in the field of water-based fluorine-containing acrylate copolymer emulsion and its preparation, can solve problems such as air pollution, non-environmental protection, and health effects of construction workers, and achieve good water and oil resistance, comprehensive and practical High performance, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

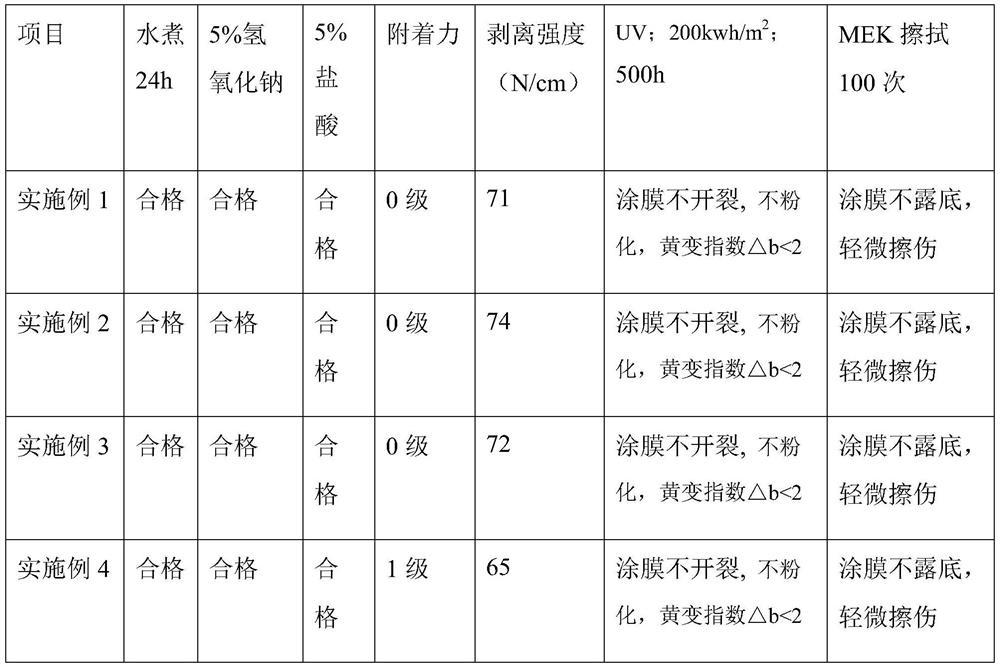

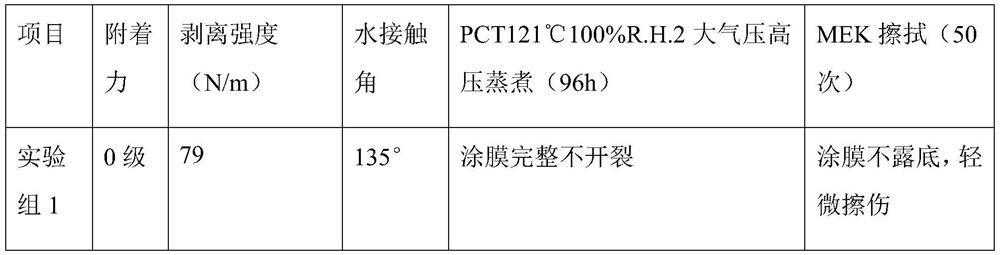

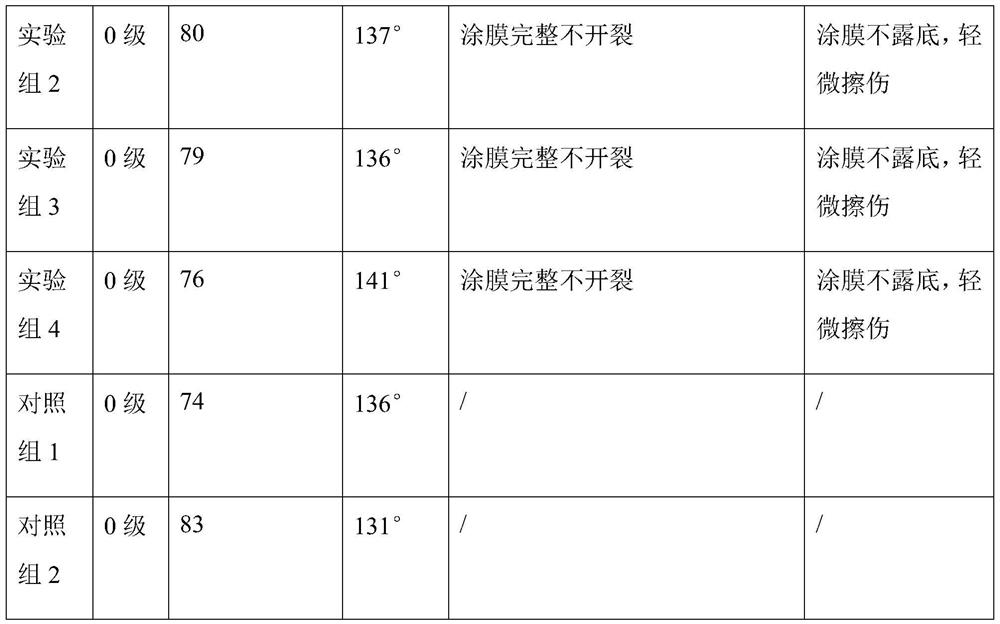

Examples

Embodiment 1

[0044] A preparation method of an aqueous fluorine-containing acrylate copolymer emulsion, comprising the following steps:

[0045] (1) Take acrylic acid, methyl methacrylate and hydroxypropyl acrylate, mix uniformly under nitrogen atmosphere, add azobisisobutyronitrile and N,N-dimethylformamide, react at 60°C for 12h, and settle in n-hexane , vacuum drying to obtain a prepolymer; the weight ratio of the acrylic acid, methyl methacrylate and hydroxypropyl acrylate is 2:1:3, and the azobisisobutyronitrile is acrylic acid, methyl methacrylate and 2 wt% of the total amount of hydroxypropyl acrylate monomers.

[0046] Mix the prepolymer and dopamine hydrochloride, dissolve the mixture of dichloromethane and dimethylformamide in a volume of 1:1, add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, stirred for 30min, added triethylamine, reacted at 25°C for 24h, washed and dried after the reaction, to obtain a dopamine-modified prepolymer; the mass ratio of the prepoly...

Embodiment 2

[0054] A preparation method of an aqueous fluorine-containing acrylate copolymer emulsion, comprising the following steps:

[0055] (1) Take acrylic acid, methyl methacrylate and hydroxypropyl acrylate, mix uniformly under nitrogen atmosphere, add azobisisobutyronitrile and N,N-dimethylformamide, react at 65°C for 11h, and settle in n-hexane , vacuum drying to obtain a prepolymer; the weight ratio of the acrylic acid, methyl methacrylate and hydroxypropyl acrylate is 2:1:3, and the azobisisobutyronitrile is acrylic acid, methyl methacrylate and 2 wt% of the total amount of hydroxypropyl acrylate monomers.

[0056] Mix the prepolymer and dopamine hydrochloride, dissolve the mixture of dichloromethane and dimethylformamide in a volume of 1:1, add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, stirred for 35min, added triethylamine, reacted at 28°C for 22h, washed and dried after the reaction to obtain a dopamine-modified prepolymer; the mass ratio of the prepolym...

Embodiment 3

[0065] A preparation method of an aqueous fluorine-containing acrylate copolymer emulsion, comprising the following steps:

[0066] (1) Take acrylic acid, methyl methacrylate and hydroxypropyl acrylate, mix uniformly under nitrogen atmosphere, add azobisisobutyronitrile and N,N-dimethylformamide, react at 70°C for 10h, and settle in n-hexane , vacuum drying to obtain a prepolymer; the weight ratio of the acrylic acid, methyl methacrylate and hydroxypropyl acrylate is 2:1:3, and the azobisisobutyronitrile is acrylic acid, methyl methacrylate and 2 wt% of the total amount of hydroxypropyl acrylate monomers.

[0067] Mix the prepolymer and dopamine hydrochloride, dissolve the mixture of dichloromethane and dimethylformamide in a volume of 1:1, add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide salt acid salt, stirred for 40min, added triethylamine, reacted at 30°C for 20h, washed and dried after the reaction, to obtain a dopamine-modified prepolymer; the mass ratio of the prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com