Nitride composite refractory material for titanium alloy smelting and preparation method thereof

A technology of refractory materials and nitrides, which is applied in the field of nitride composite refractory materials for titanium alloy smelting and its preparation, can solve the problems of no patents and literature reports, unavailable refractory materials, difficulties in the preparation of single crucibles, etc., and achieve excellent Anti-corrosion performance of titanium melt, low oxygen content, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A nitride composite refractory material for smelting titanium alloy, according to the mass percentage of components, its main components are: boron nitride powder 20%, aluminum nitride powder 80%; The additive is yttrium oxide; the particle size of the boron nitride powder is 1 to 3 μm (boron nitride is used as a composite active agent, in order to promote the sintering and compactness of the composite material, so its particle size should be ≤ the particle size of aluminum nitride), and the aluminum nitride powder has a particle size of 1 to 3 μm. The particle size is 3-5 μm; the purity of the boron nitride powder is greater than 99.5%, and the purity of the aluminum nitride powder is greater than 99.9%.

[0034] The preparation method of the nitride composite refractory material for titanium alloy smelting comprises the following steps:

[0035] ①Preparation of composite refractory powder: After weighing all the raw materials according to the mass percentage of the co...

Embodiment 2

[0044] A nitride composite refractory material for smelting titanium alloy, according to the mass percentage of components, its main components are: boron nitride powder 10%, aluminum nitride powder 90%; Other component conditions and preparation conditions are the same as in Example 1.

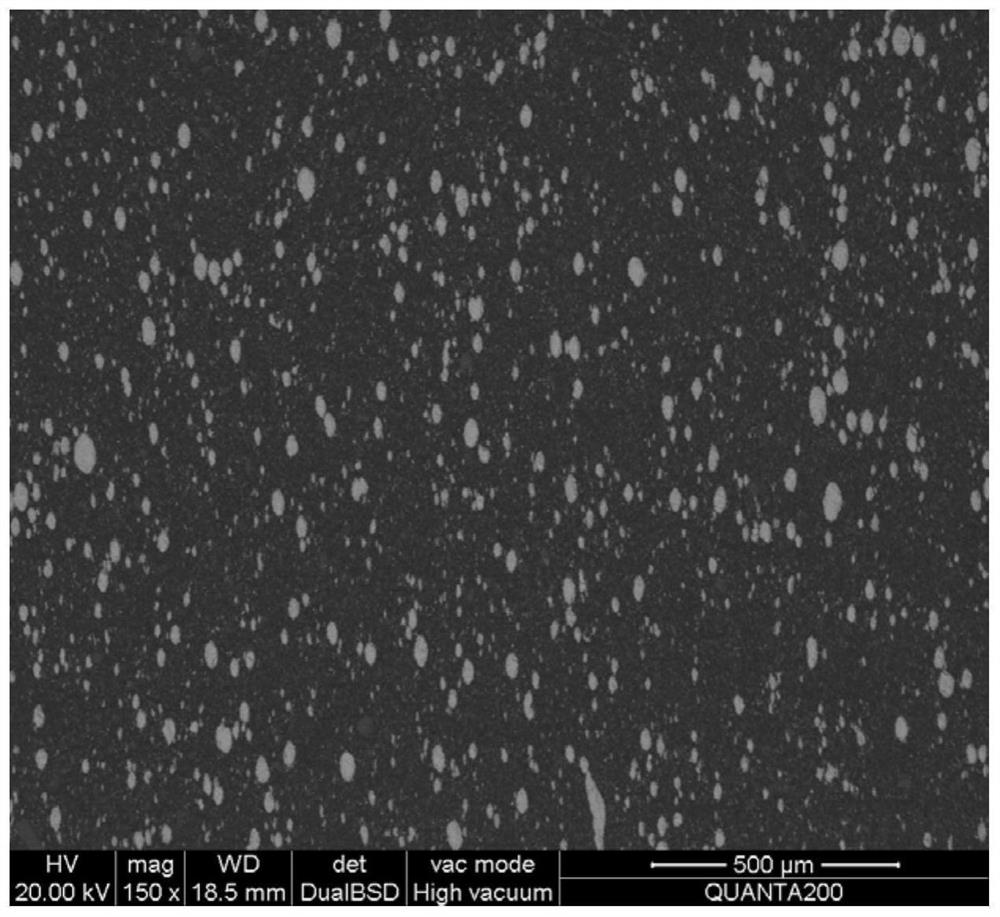

[0045] The composite refractory prepared in this example has a relatively uniform structure and high density, see Figure 4 , after testing: the finished product density of composite refractory is 2.7428g / cm 3 , its theoretical density is 3.1275g / cm 3 , the relative density reaches 87.7%.

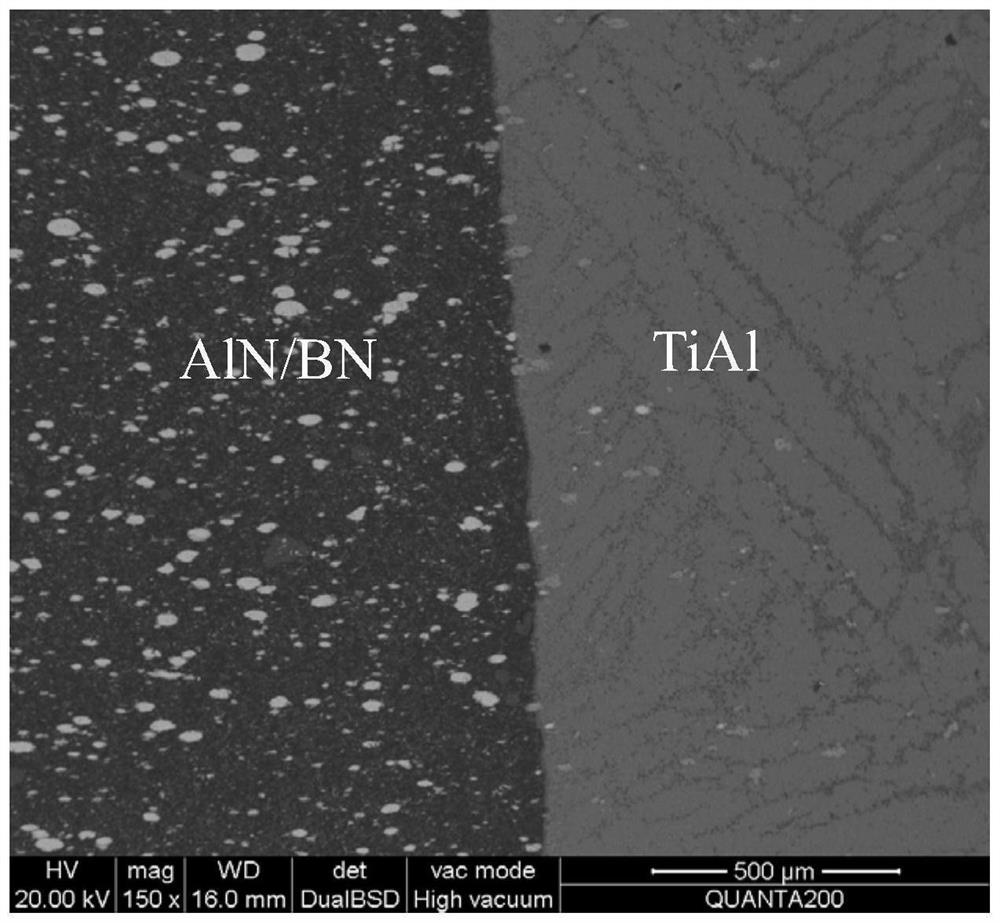

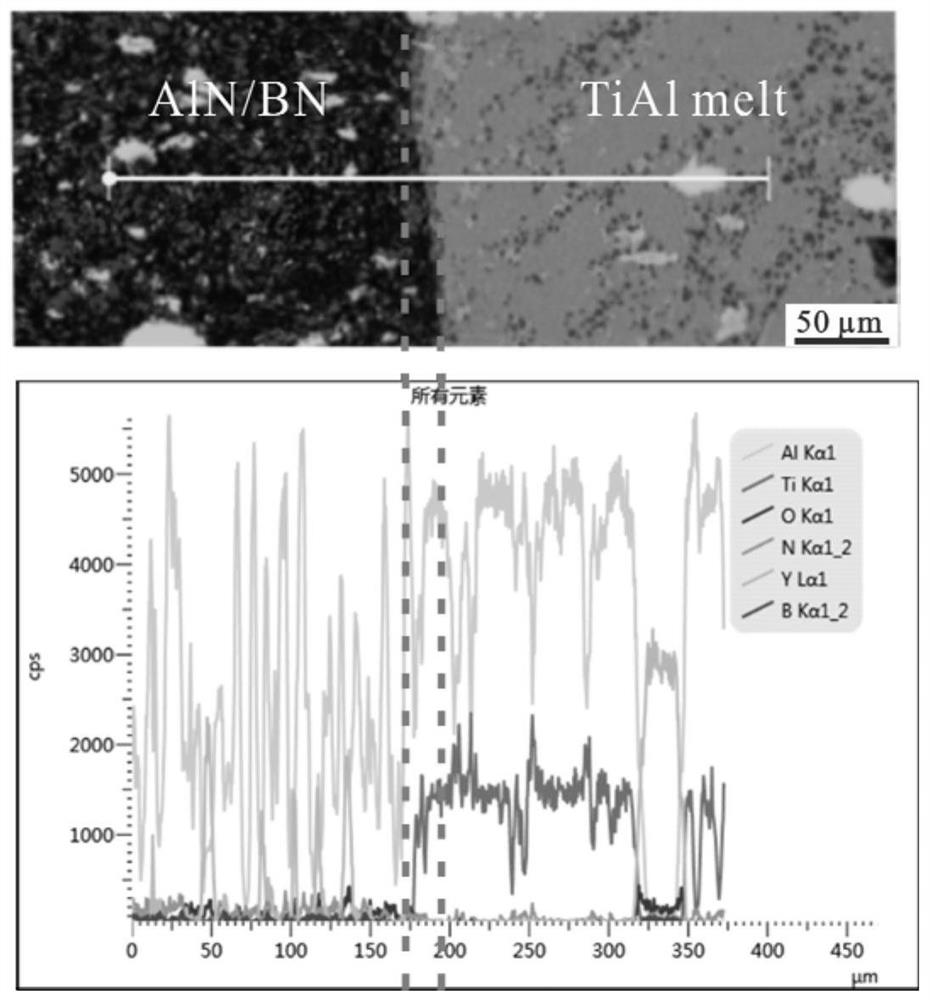

[0046] The composite refractory prepared in this example is relatively stable in quality and excellent in corrosion resistance. It is applied in a vacuum melting furnace to smelt titanium-aluminum alloy (Ti-48Al, at% ), after testing: the surface of the composite refractory after smelting is relatively flat and not significantly corroded by the titanium melt, see Figure 5 ; The interface reaction laye...

Embodiment 3

[0049] A nitride composite refractory material for smelting titanium alloy, according to the mass percentage of components, its main components are: boron nitride powder 40%, aluminum nitride powder 60%; Other component conditions and preparation conditions are the same as in Example 1.

[0050] The composite refractory prepared in this example has a relatively uniform structure and high density. After testing, the finished product density of the composite refractory is 2.3891g / cm 3 , its theoretical density is 2.7877g / cm 3 , the relative density reaches 85.7%.

[0051] The composite refractory prepared in this example is relatively stable in quality and excellent in corrosion resistance. It is applied in a vacuum melting furnace to smelt titanium-aluminum alloy (Ti-48Al, at% ), after testing: the surface of the composite refractory after smelting is relatively flat, not significantly eroded by the titanium melt, the refractory-titanium-aluminum alloy interface reaction laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com