Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

An in-situ synthesis and porous material technology, which is applied in the field of metal foam materials, can solve the problems of material performance deterioration, short durability, poor corrosion resistance, etc., and achieve performance improvement, easy control of composition, and uniform pore structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

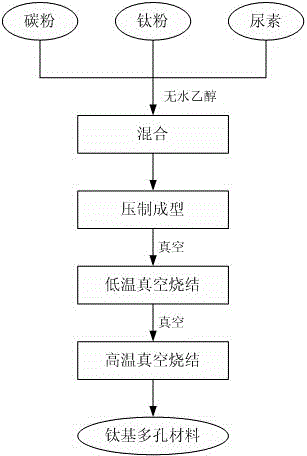

[0034]This example provides a preparation method for in-situ synthesis of titanium carbide reinforced titanium-based porous materials, the process of which refers to figure 1 As shown, the main steps include the following:

[0035] (1) Ingredients:

[0036] Weigh 2 parts by weight of carbon powder and 98 parts by weight of titanium powder to form a mixed powder with a total weight of 100 parts by weight, and add urea with the same volume as the 100 parts by weight of mixed powder, mix in the research body, and in the mixing process Add absolute ethanol according to the ratio of 5~10ml of absolute ethanol per kilogram of carbon powder, titanium powder and urea mixture; the addition of absolute ethanol is conducive to the uniform mixing of urea, titanium powder and carbon powder, thereby changing the sintering process. The pore structure of the bulk porous titanium-based composite material, but if too much absolute ethanol is added, it is also not conducive to the mixing of ure...

Embodiment 2

[0044] In this example, a preparation method for in-situ synthesis of titanium carbide-reinforced titanium-based porous materials refers to the process flow figure 2 , the main steps include the following:

[0045] (1) Weighing 1 part by weight of carbon powder and 99 parts by weight of titanium powder to form a mixed powder with a total weight of 100 parts by weight, and adding urea of the same volume as the 100 parts by weight of mixed powder, mixing in the research body, and During the mixing process, absolute ethanol is added at a ratio of 5-10ml of absolute ethanol per kilogram of the mixture of carbon powder, titanium powder and urea; among them, the carbon powder is ultrafine carbon powder with a purity of 99.99% and a particle size of 400 ~500 mesh, the particle size of urea is 1.00~1.18mm, and the particle size of titanium powder is 300~400 mesh.

[0046] (2) Use a steel mold to statically press the mixture obtained in the previous step. The one-way pressing press...

Embodiment 3

[0050] In this example, a preparation method for in-situ synthesis of titanium carbide-reinforced titanium-based porous materials refers to the process flow figure 2 , the main steps include the following:

[0051] (1) Weigh 1.5 parts by weight of carbon powder and 98.5 parts by weight of titanium powder to form a mixed powder with a total weight of 100 parts by weight, and add urea of the same volume as the 100 parts by weight of mixed powder, mix in the research body, and During the mixing process, absolute ethanol is added at a ratio of 5-10ml of absolute ethanol per kilogram of the mixture of carbon powder, titanium powder and urea; among them, the carbon powder is ultrafine carbon powder with a purity of 99.99% and a particle size of 400 ~500 mesh, the particle size of urea is 1.00~1.18mm, and the particle size of titanium powder is 300~400 mesh.

[0052] (2) Use a steel mold to statically press the mixture obtained in the previous step. The one-way pressing pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com