Super duplex stainless steel flux-cored wire for impeller additive repair and preparation method and application of super duplex stainless steel flux-cored wire

A duplex stainless steel and flux-cored welding wire technology, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve the problem that there is no wire for additive repair of super duplex stainless steel impellers, and achieve high-efficiency, reliable and quality-guaranteed defect repair , Improving the ability to resist intergranular corrosion and increasing the Cr content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

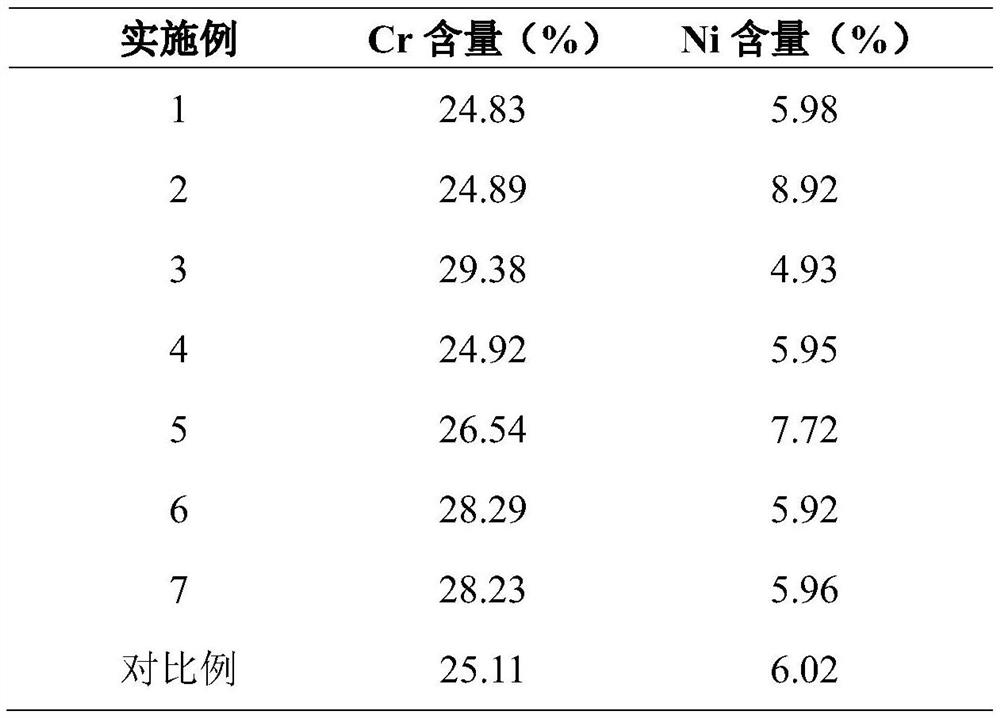

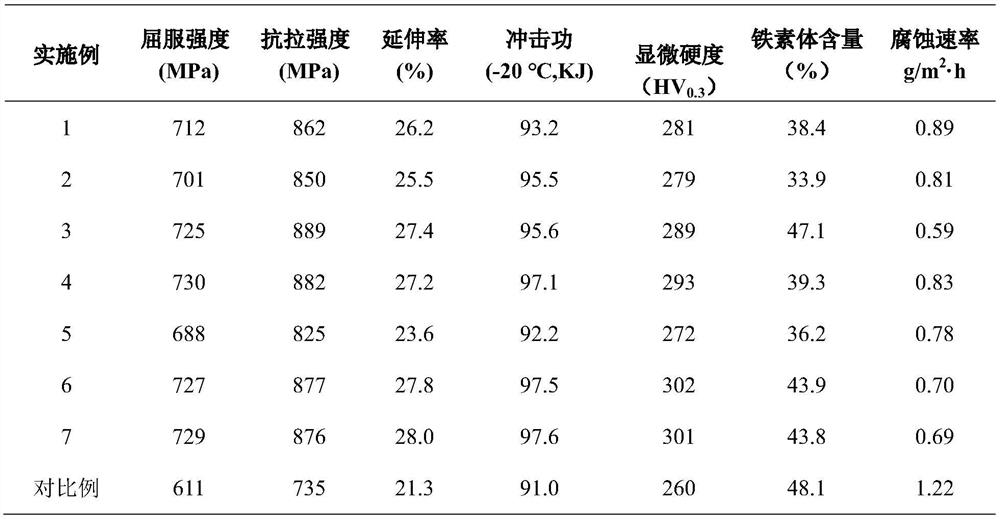

[0028] A super duplex stainless steel flux-cored welding wire for impeller additive repair, using S32205 duplex steel strip (chemical composition mass fraction: 22.0% Cr, 5.0% Ni, 3.5% Mo, 0.20% N, the balance is iron and impurities) is the outer skin, the width of the outer skin is 12mm, and the thickness is 0.6mm; the filling amount of the flux-cored powder (the percentage of the flux-cored powder in the total mass of the welding wire) is 30%; the diameter of the flux-cored welding wire is 1.6mm. The super duplex stainless steel model used in the manufacture of the super duplex stainless steel impeller is S32750. In terms of mass fraction, the core powder is composed of the following components: chromium 6.04%, nickel 1.30%, molybdenum 0.84%, tungsten 1.50%, silicon 0.12%, yttrium carbonate 1.30%, zirconium-nickel alloy powder (containing 70.00% Zr) 4.00 %, high nitrogen ferrochromium (containing 10.0% N, 65% Cr) 4.32%, anatase 0.90%, mullite 1.10%, and the balance is Fe. T...

Embodiment 2

[0034] A super duplex stainless steel flux-cored welding wire for impeller additive repair, using S32205 duplex steel strip (chemical composition mass fraction: 22.0% Cr, 5.0% Ni, 3.5% Mo, 0.20% N, the balance is iron and impurities) is the outer skin, the width of the outer skin is 12mm, and the thickness is 0.6mm; the powder filling amount (the percentage of the flux cored powder in the total mass of the welding wire) is 30%; the diameter of the flux cored welding wire is 1.6mm. The super duplex stainless steel model used in the manufacture of the super duplex stainless steel impeller is S32750. In terms of mass fraction, the core powder is composed of the following components: chromium 6.04%, nickel 4.30%, molybdenum 0.84%, tungsten 1.50%, silicon 0.12%, yttrium carbonate 1.30%, zirconium-nickel alloy powder (containing 70.00% Zr) 4.00 %, high nitrogen ferrochromium (containing 10.0% N, 65% Cr) 4.32%, anatase 0.90%, mullite 1.10%, and the balance is Fe. The Cr content in t...

Embodiment 3

[0037] A super duplex stainless steel flux-cored welding wire for impeller additive repair, using S32205 duplex steel strip (chemical composition mass fraction: 22.0% Cr, 5.0% Ni, 3.5% Mo, 0.20% N, the balance is iron and impurities) is the outer skin, the width of the outer skin is 12mm, and the thickness is 0.6mm; the powder filling amount (the percentage of the flux cored powder in the total mass of the welding wire) is 30%; the diameter of the flux cored welding wire is 1.6mm. The super duplex stainless steel model used in the manufacture of the super duplex stainless steel impeller is S32750. In terms of mass fraction, the core powder is composed of the following components: chromium 11.24%, nickel 0.30%, molybdenum 0.84%, tungsten 1.50%, silicon 0.12%, yttrium carbonate 1.30%, zirconium-nickel alloy powder (including 70.00% Zr) 4.00 %, high nitrogen ferrochromium (containing 10.0% N, 65% Cr) 4.32%, anatase 0.90%, mullite 1.10%, and the balance is Fe. The Cr content in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com