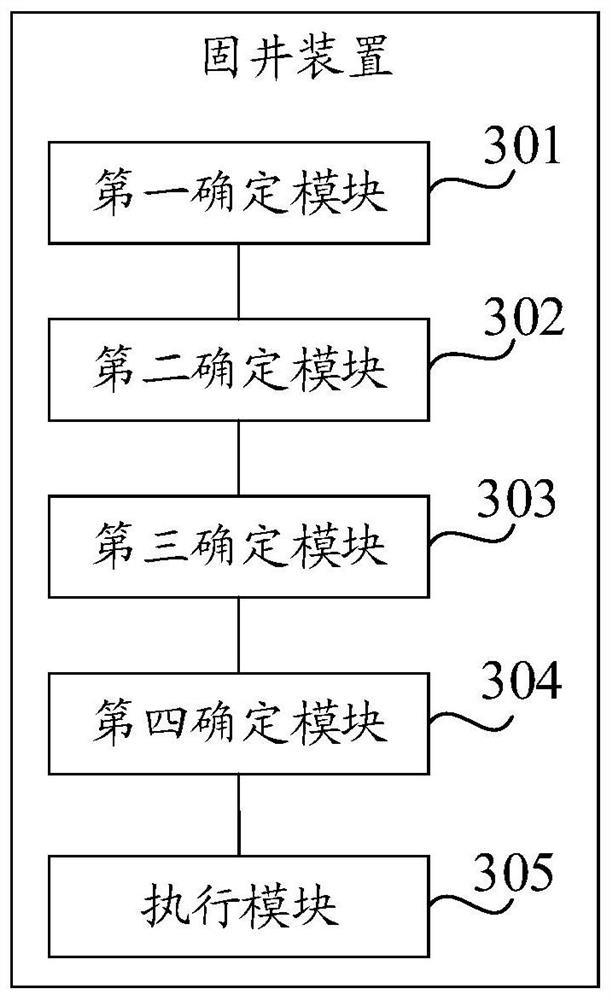

Well cementing method, device and storage medium

A cementing and density technology, which is applied in earthwork drilling, wellbore/well components, construction, etc., can solve problems such as gas invasion and cement slurry leakage, and achieve the effect of avoiding leakage and gas invasion and improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

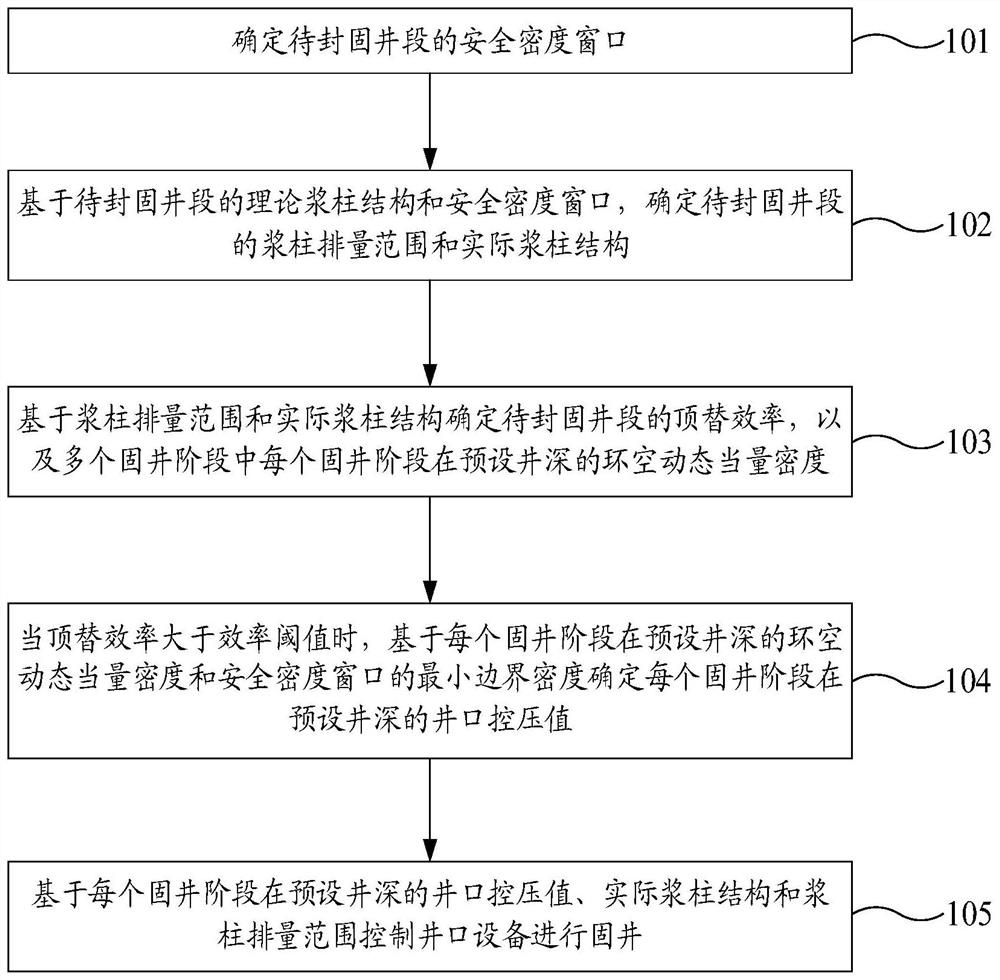

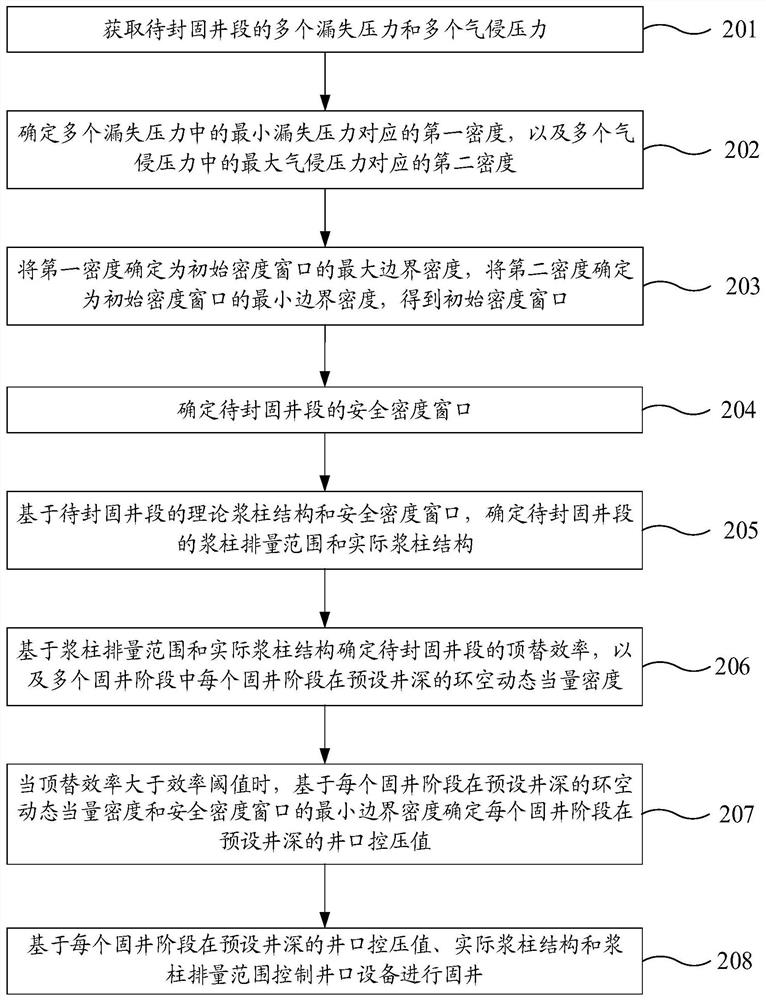

[0060] figure 1 It is a schematic flow chart of a cementing method provided by the embodiment of the present application. see figure 1 , the method includes the following steps.

[0061] Step 101: Determine a safe density window of the well section to be sealed, where the safe density window refers to a density range between the gas invasion pressure equivalent density and the leakage pressure equivalent density of the well section to be sealed;

[0062] Step 102: Based on the theoretical slurry column structure and the safe density window of the well section to be sealed, determine the slurry column displacement range and the actual slurry column structure of the to-be-sealed well section;

[0063] Step 103: Determine the displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com