Microclimate Control System for Concrete Warehouse

A control system and climate control technology, applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, can solve potential safety hazards, reduce direct exposure of concrete, affect the strength of pouring silos, etc., to prevent The effect of temperature inversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

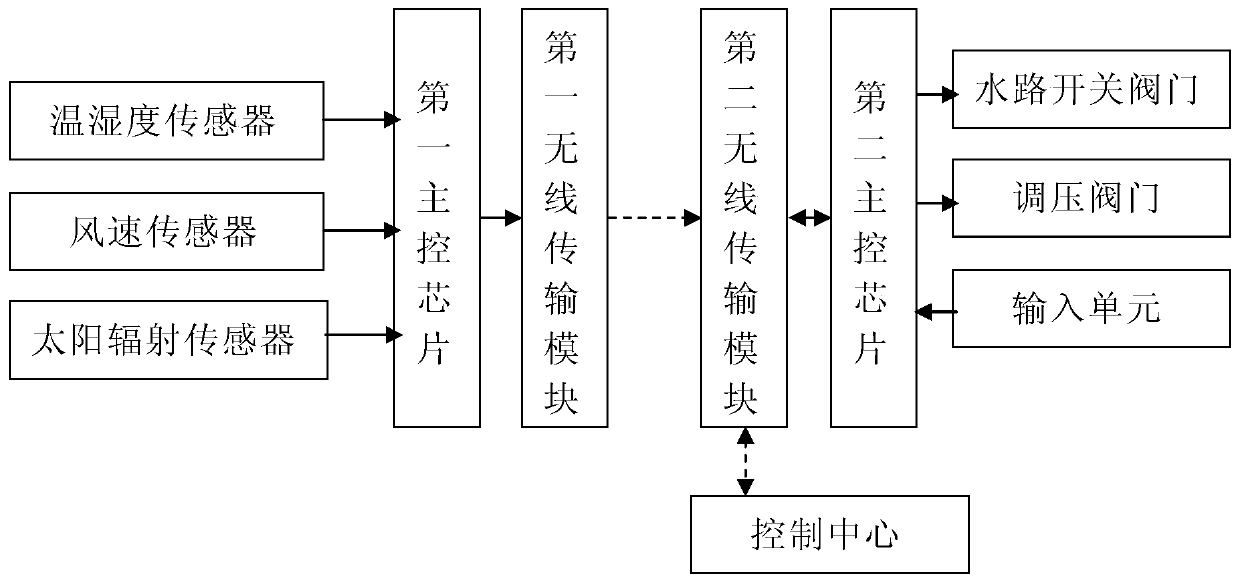

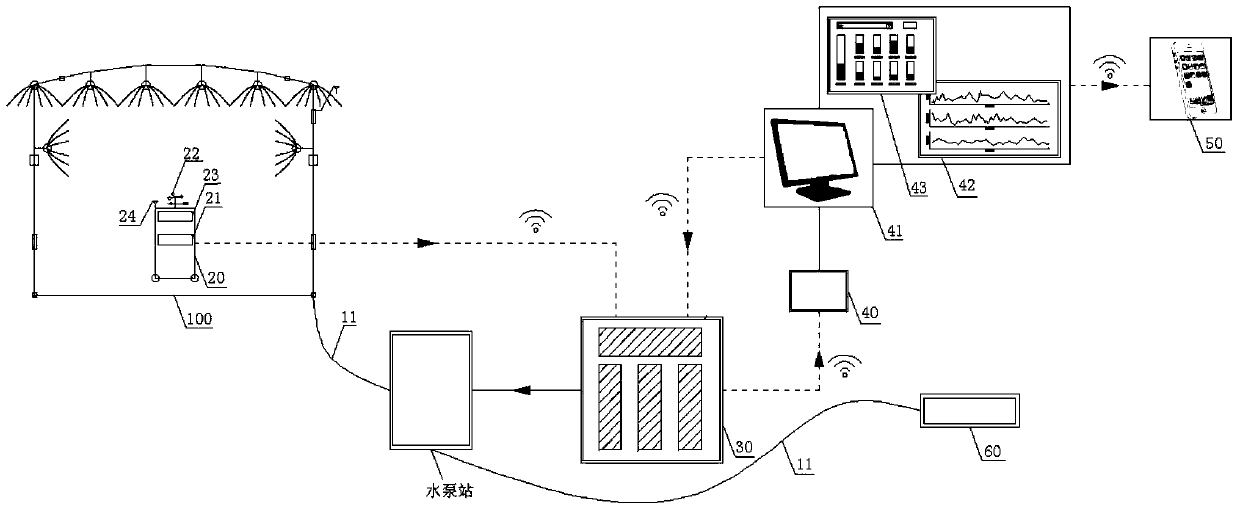

[0028] figure 1 is a system composition block diagram of the present invention, figure 2 It is a topological diagram of the system structure of the present invention. As shown in the figure, the microclimate control system for the concrete warehouse surface disclosed by the present invention includes a spray mechanism 100, a data acquisition subsystem 20, a warehouse surface climate control subsystem 30, and a control center 40.

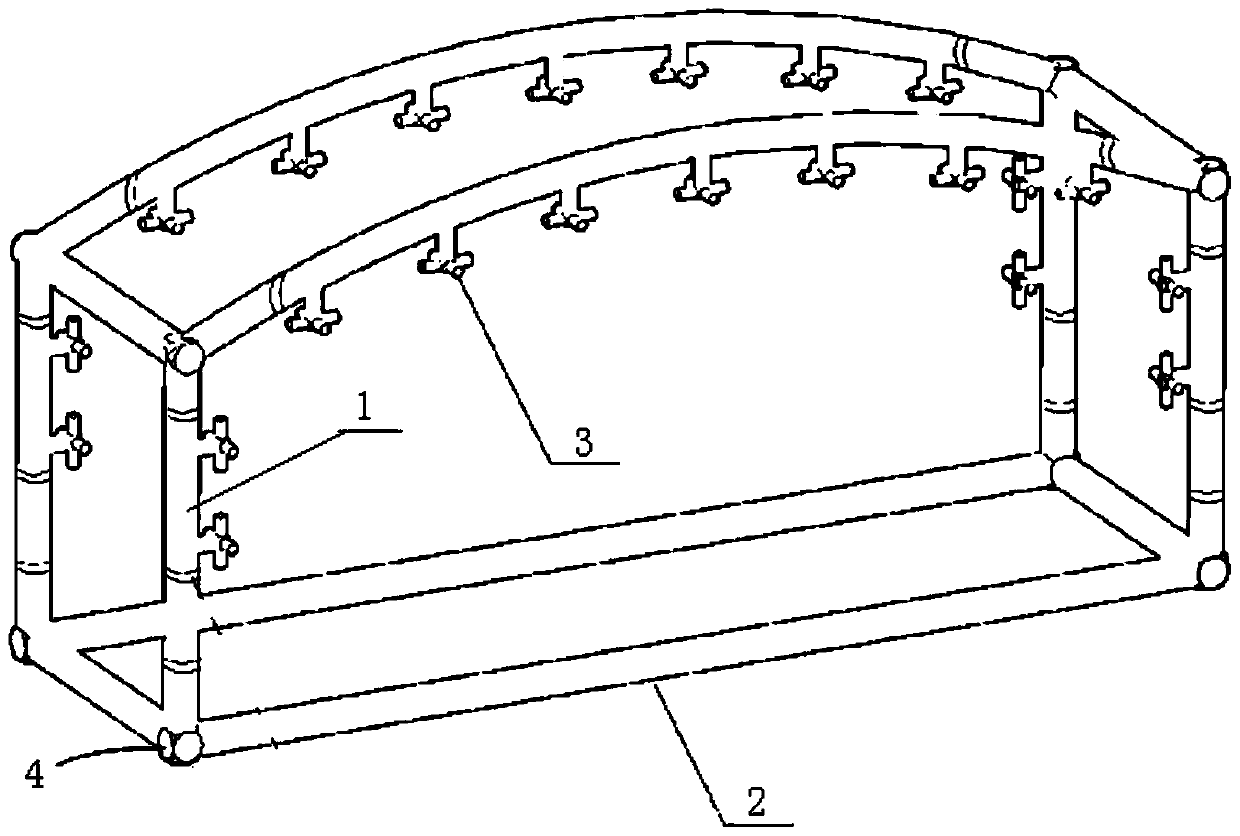

[0029] Such as image 3 As shown, the spray mechanism 100 can be a spray rack, which is erected in the area above the concrete warehouse surface. The spray rack includes a base and a frame body on the base. The frame body is constructed by several columns 1 and connecting beams 2. The frame body A number of spray heads 3 are arranged on the frame body, and a number of water delivery pipes corresponding to each spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com