Preparation method of micro-channel plate and micro-channel plate prepared by preparation method

A microchannel plate and columnar technology, which is applied in separation methods, chemical instruments and methods, discharge tube/lamp manufacturing, etc., can solve the difficulty of making uniform film materials on the inner wall of microchannels, substrate deformation, and large aspect ratio holes. Micro-hole etching and other issues, to achieve the effect of excellent structure and device performance, low cost, and avoid material limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] According to a specific embodiment of the present invention, a kind of preparation method of microchannel plate is provided, such as Figure 3a-3f , including the following steps:

[0051] 1) Provide a substrate 301 .

[0052] The substrate 301 suitable for this embodiment can be a smooth and flat substrate. Exemplary substrates 301 include, but are not limited to, surface-polished silicon wafers, metal sheets, glass sheets, or flatness and roughness that meet micromachining, especially photolithography processes. Other materials required.

[0053] The size of the substrate 301 is preferably a micro-processing standard size, such as 2 inches, 3 inches, 4 inches, 6 inches, or a standard substrate and non-standard substrate larger than 6 inches that can be achieved by micro-processing.

[0054] A suitable thickness of the substrate 301 is preferably 400-2000 microns.

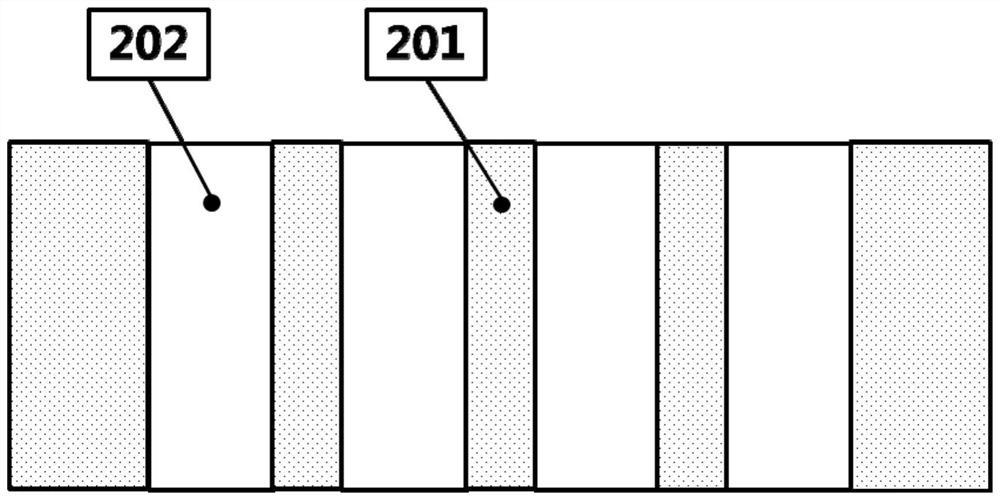

[0055] 2) forming a columnar array 302 at a preselected position on one surface of the substrate 301,...

Embodiment 1

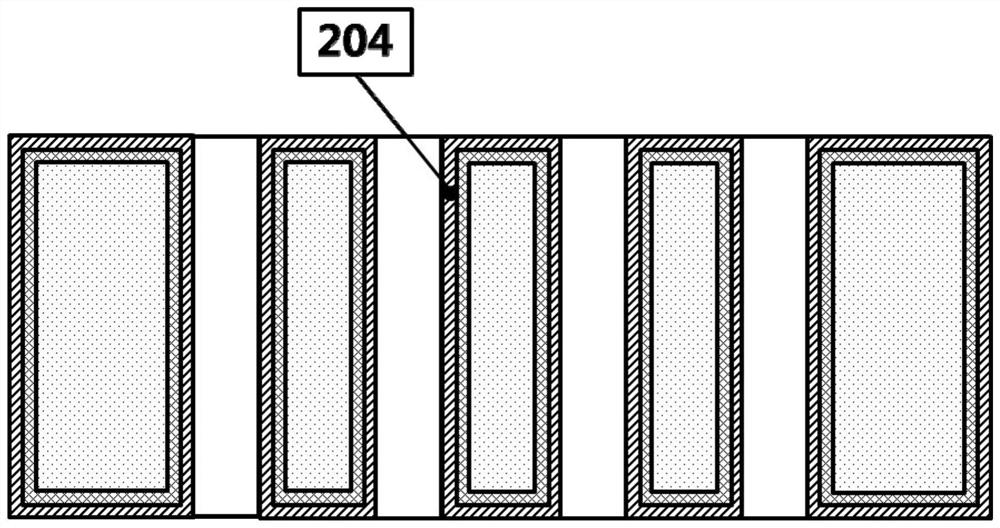

[0090] A microchannel plate, as shown in FIG. 3 , includes an electron multiplication layer 401 , a microchannel plate substrate 402 , an electron transmission channel 403 , an input electrode 404 and an output electrode 405 .

[0091] Its preparation method comprises the following steps:

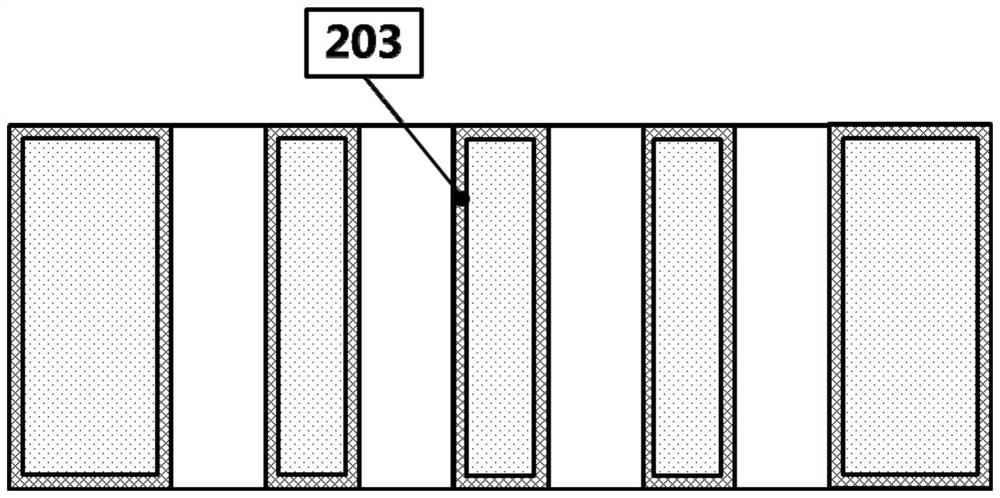

[0092]1) Choose crystal-oriented polished silicon wafer as the substrate 301, the diameter of the silicon wafer is 4 inches, the thickness is 500 microns, the surface flatness and warpage are better than 10 microns; the surface of the silicon wafer is thermally oxidized with 0.5 micron silicon dioxide and magnetron Sputter 1 micron metal aluminum, through standard photolithography, etch silicon dioxide and metal aluminum as a mask layer; use Bosch patented deep silicon etching technology of STS company, etch silicon substrate to form columnar array 302; etching power 600W / 15W, etching rate 1.5μm / min, etching time 200min, etching depth 300μm; according to the design pattern, a dense hexago...

Embodiment 2

[0099] A microchannel plate includes an electron multiplication layer 401 , a microchannel plate substrate 402 , an electron transmission channel 403 , an input electrode 404 and an output electrode 405 .

[0100] Its preparation method is with embodiment 1, and difference is:

[0101] In step 1), select crystal direction polished silicon wafer as the substrate 301, the diameter of the silicon wafer is 4 inches, the thickness is 500 microns, and the surface flatness and warpage are better than 10 microns; 300 microns are spin-coated on the surface of the substrate 301 with 800 RPM Thickness SU8-2150 photoresist, pre-baked at 95°C for 60 minutes, according to the design pattern 600mJ / cm 2 Dose exposure, post-bake at 95°C for 60 minutes, develop with SU8Developer for 45 minutes, and obtain a dense hexagonal columnar array 302 on the silicon wafer. aspect ratio 20.

[0102] In step 3), the chemical vapor deposition method is used to deposit silicon dioxide in the gap between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com