Strip support and alignment device, particularly for strips to be cut in a cutting machine

A technology of alignment device and cutting device, which is applied in the directions of transportation and packaging, application, winding strips, etc., can solve the problems of inefficient processing of layer groups, accurate angular alignment and centering of material strips, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

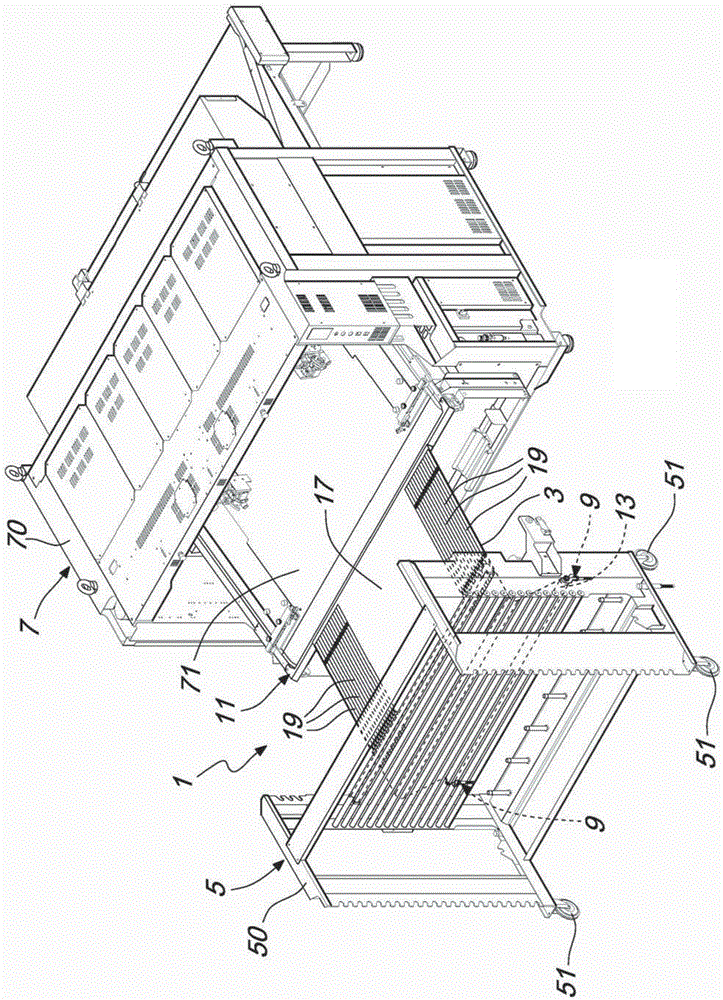

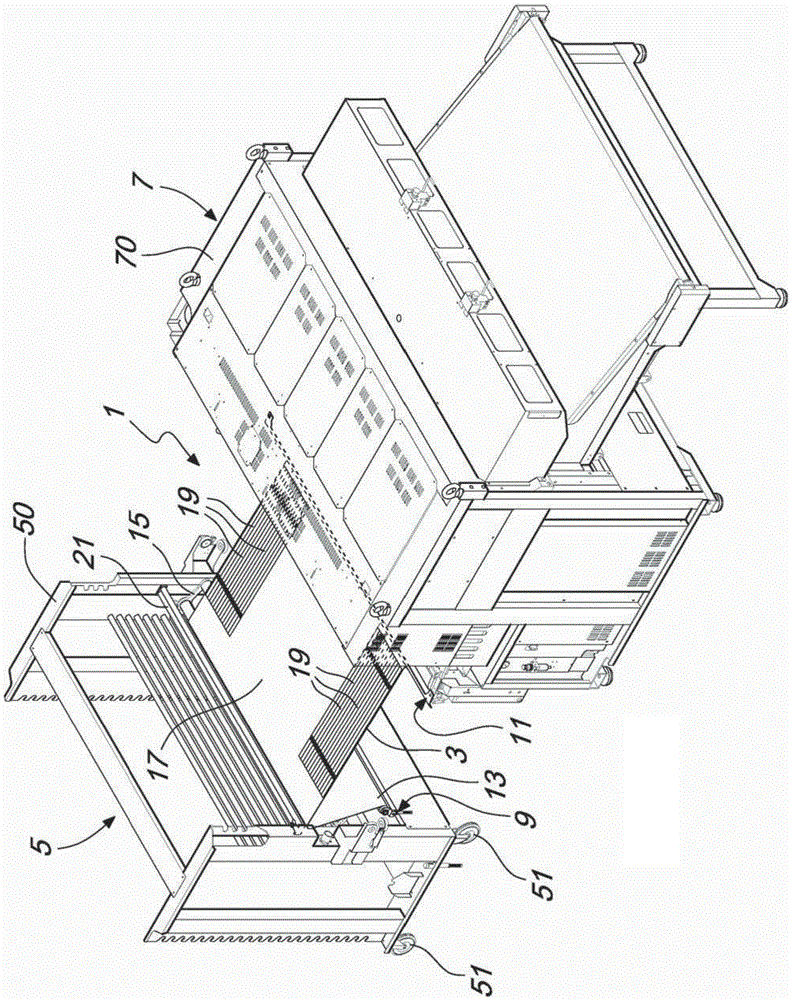

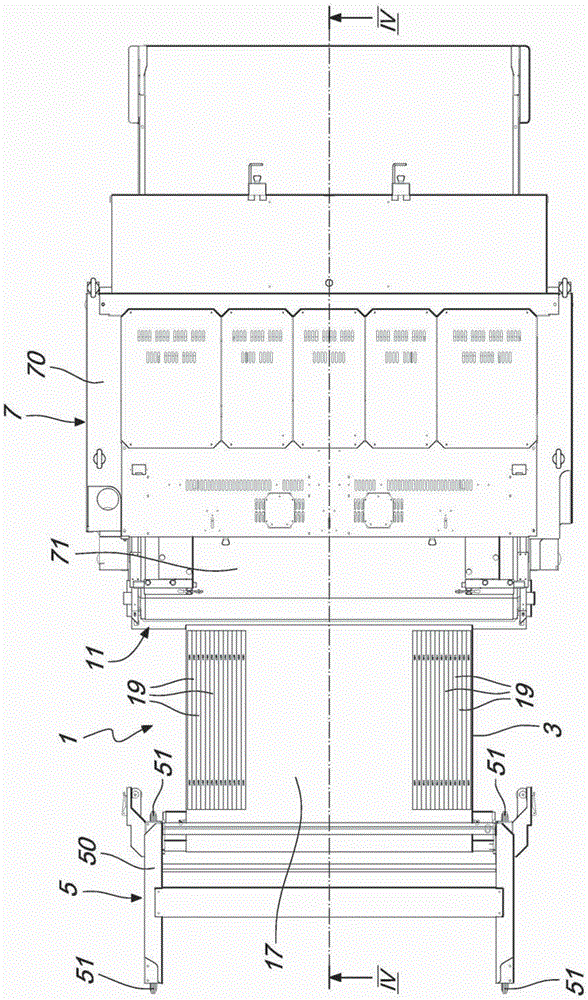

[0026] With reference to the figures, a strip support and alignment device, in particular for a strip to be cut in a cutting machine, is generally indicated with the reference number 1 .

[0027] According to the invention, the strip support and alignment device 1 comprises:

[0028] - a sheet 3 extending between a station 5 for feeding at least one strip (not shown) and a station 7 for processing the strip, defining a support and alignment surface 17 for said strip,

[0029] - first means 9 for securing the sheet 3 to the feeding station 5,

[0030] - a second device 11 for securing the sheet 3 to the processing station 7,

[0031] - means 13 for winding and unwinding the sheet 3 , adapted to wind or unwind the sheet 3 to vary its length according to the distance between the feeding station 5 and the processing station 7 .

[0032] The feeding station 5 may comprise a rack unwinding device 50, or a single or multiple such as Figures 1 to 4 The gantry unwinder 50 shown is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com