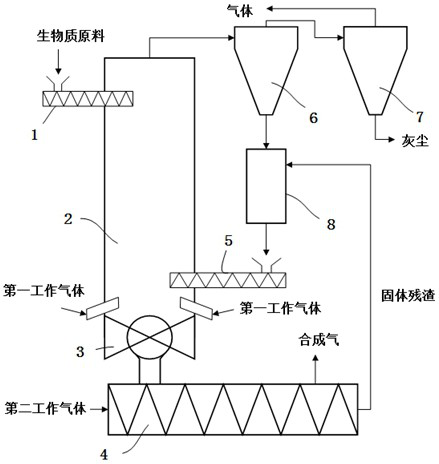

Biomass pyrolysis gasification method and system

A technology for pyrolysis gasification and biomass, which is applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve problems such as unfavorable obtaining of high-quality gas, poor stability of tar, easy coking and corrosion, and influence of gas calorific value, etc. Achieve the effect of improving microwave energy utilization efficiency, reducing external energy consumption, and reducing process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The dried biomass is crushed to less than 2mm, and then physically extruded under the condition of 20MPa to obtain biomass raw materials, and the biomass raw materials with a maximum dimension of 40mm are obtained.

Embodiment 2

[0044] The biomass raw material of Example 1 and heat carrier 1 (the mass ratio of olivine, alumina, and nickel oxide is 1:0.5:0.05) are sent to the preprocessor according to the mass ratio of 1:5, and the first working gas steam Flow 5m 3 Under the action of / h, at a temperature of 600°C and a heating time of 30 seconds, solid-solid rapid contact and heat exchange are carried out to obtain biomass raw materials and gas phase materials with external carbonization and internal surface carbonization, and the gas phase materials are obtained after separation. The gas is recycled back to the preprocessor for use. Among them, the surface carbonized biomass raw material accounts for 65%; the above-mentioned surface carbonized biomass raw material is sent to the microwave pyrolyzer, and the flow rate of the second working gas (the mass ratio of potassium carbonate to water vapor is 0.05:1) is 0.5m 3 Under the action of / h, the temperature is 500°C; the reaction time is 30 minutes; t...

Embodiment 3

[0046] The biomass raw material of embodiment 1 and heat carrier 2 (the mass ratio of olivine, aluminum oxide, nickel oxide is 1: 5: 0.5) are sent into preprocessor according to mass ratio 1: 10, in the first working gas (acetic acid The mass ratio to water vapor is 0.05:1) The flow rate is 10m 3 Under the action of 700°C and heating time of 20 seconds, rapid solid-solid contact and heat exchange are carried out under the action of / h, to obtain biomass raw materials with external carbonization and internal surface carbonization, of which the surface carbonization biomass raw materials account for 85% %; Send the above-mentioned surface carbonized biomass raw materials into the microwave pyrolyzer, and the flow rate of the second working gas (the mass ratio of potassium carbonate to water vapor is 0.1:1) is 0.5m 3 Under the action of / h, at a temperature of 800°C, the reaction time is 8 minutes; the microwave power density is 3×10 5 W / m 3 Under these conditions, a high-quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com