Heterojunction solar cell and preparation method thereof

A solar cell and heterojunction technology, applied in the field of solar cells, can solve the problems affecting the photoelectric conversion efficiency of heterojunction solar cells, the transparent conductive oxide film is easily damaged, and the battery contact resistance/series resistance is large, so as to achieve improvement Photoelectric conversion efficiency, avoiding poor adhesion, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

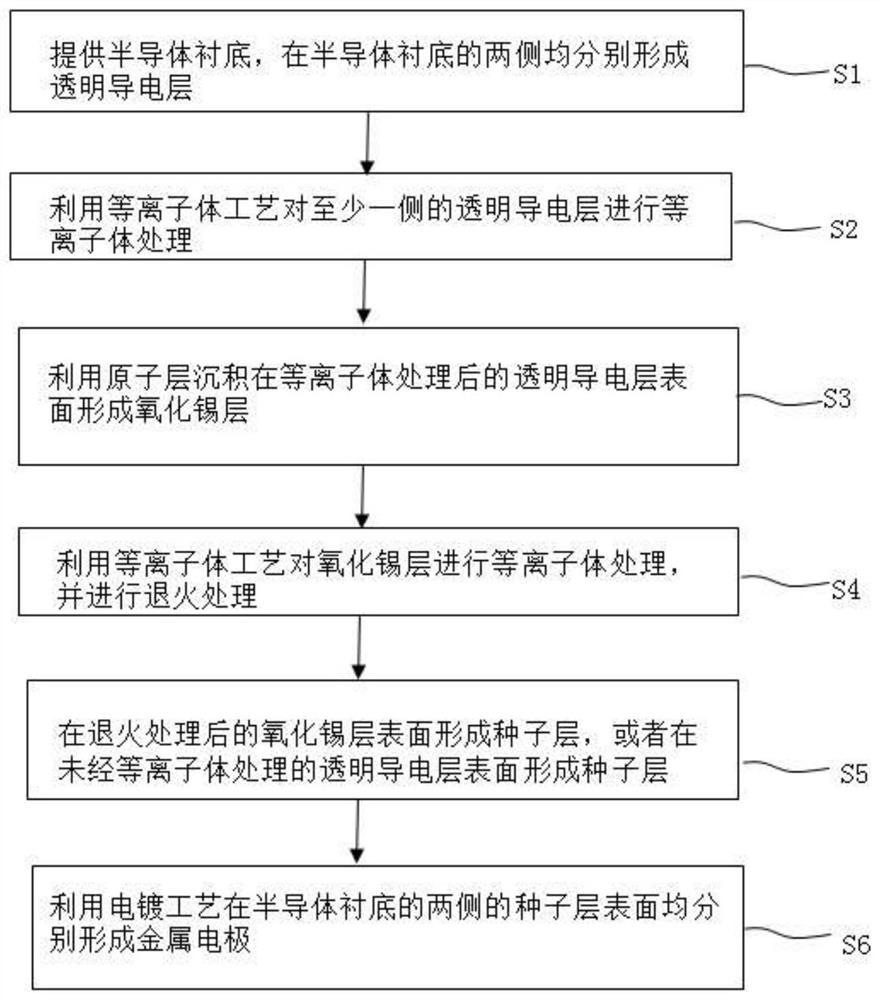

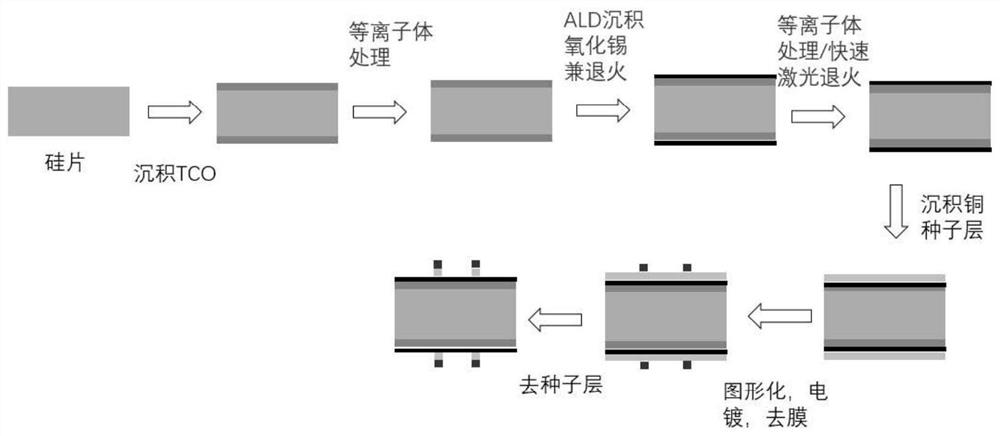

[0040] see figure 1 or figure 2 As shown, in some embodiments, a method for preparing a heterojunction solar cell is provided, the method comprising:

[0041] S1. Provide a semiconductor substrate, and form transparent conductive layers on both sides of the semiconductor substrate;

[0042] S2. Using a plasma process to perform plasma treatment on at least one side of the transparent conductive layer;

[0043] S3, forming a tin oxide layer on the surface of the plasma-treated transparent conductive layer by atomic layer deposition;

[0044] S4, using a plasma process to perform plasma treatment on the tin oxide layer, and perform annealing treatment;

[0045] S5, forming a seed layer on the surface of the annealed tin oxide layer, or forming a seed layer on the surface of the non-plasma-treated transparent conductive layer;

[0046] S6 , forming metal electrodes on the surfaces of the seed layers on both sides of the semiconductor substrate by using an electroplating proc...

Embodiment 1

[0090] S11. Depositing the first intrinsic amorphous silicon layer 2 and the first doped layer 3 (such as phosphorous-doped amorphous or microcrystalline silicon layer), and deposit a second intrinsic amorphous silicon layer 4 and a second doped layer 5 (such as a boron-doped amorphous or microcrystalline silicon layer) in sequence on the back of the semiconductor substrate 1 .

[0091] Wherein, the deposition conditions of the first intrinsic amorphous silicon layer or the second intrinsic amorphous silicon layer are: the power supply is 500W, the gas flow ratio of hydrogen to silane (hydrogen dilution ratio) is 9.5:1, and the pressure is 50Pa. The substrate temperature was 220°C. The deposition conditions of the phosphorus-doped amorphous or microcrystalline silicon layer are: the power supply is 400W, the gas flow ratio of hydrogen to silane (hydrogen dilution ratio) is 5.5:1, and the gas flow ratio of phosphine to silane (phosphorus to silicon ratio) The ratio is 1:109, t...

Embodiment 2

[0101] The preparation method of embodiment 2 is basically the same as that of embodiment 1, and the similarities are not repeated, and the difference is:

[0102] In Example 2, in step S12, a magnetron sputtering coating device is used to deposit a TCO film, and argon and oxygen are introduced at room temperature, the gas flow ratio of argon and oxygen is set at 55:1, and the chamber pressure is maintained at 0.35Pa, turn on the sputtering power supply, the power density of the power supply is 4KW / m, and deposit the first transparent conductive layer on the surface of the first doped layer by magnetron sputtering. On the other side of the battery, argon and oxygen are introduced, the gas flow ratio of argon and oxygen is set at 30:1, the chamber pressure is kept at 0.35Pa, and the sputtering power supply is turned on. The power density of the power supply is 4KW / m. A second transparent conductive layer is deposited on the surface of the second doped layer. Wherein, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com