Preparation method of high-cleanliness metal foil and preparation method of metal mask plate strip

A technology of metal foil and high cleanliness, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problem that the uniformity is difficult to control properly, processing or use is not as good as etching, and the composition of metal foil is limited, etc. low investment in manufacturing equipment, good cleanliness and purity, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

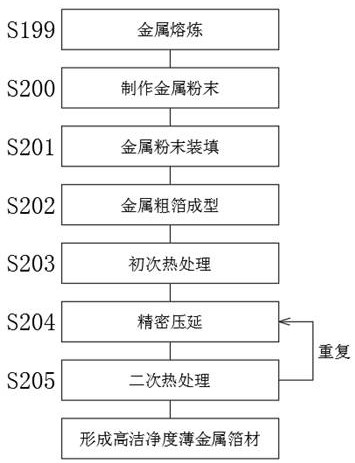

[0071] Such as figure 2 As shown, a method for preparing a high-clean metal foil material described in this embodiment specifically includes the following steps:

[0072] S201, metal powder filling; clean metal powder is filled into the metal powder dispenser of the laser welding processing equipment after being screened by particle size, wherein the material of the metal powder is Invar alloy, and the mass percentage of Invar alloy is Ni: 35 ~39wt%, the balance is Fe and other trace elements; among them, the metal powder within the required powder particle size range is selected during screening.

[0073] S202, metal rough foil forming; the metal powder dispenser uniformly injects the metal powder onto the substrate on the working platform in the laser welding processing equipment to form a metal powder layer, and then uses the laser plane scanner in the laser welding processing equipment to The metal powder layer is welded into a metal thick foil; the thickness of the meta...

Embodiment 2

[0090] Such as figure 2 As shown, the preparation method of a high-clean metal foil material described in this embodiment is roughly the same as that of Embodiment 1, the only difference is that it also includes a metal powder forming step, which is specifically as follows:

[0091] S199, metal smelting; smelting the selected high-purity metal materials by means of vacuum smelting, so that the metal materials are in a molten state; when selecting pure metals, select some with a purity higher than 99%, an oxygen content 4 Pa or 10 -4 -100mbar, melting power is 200~1200KW.

[0092] S200, making metal powder; the molten metal is atomized, cooled, and solidified to form fine clean metal powder; the molten metal is atomized in an inert, reducing, or vacuum atmosphere, and the particle size of the powder The size range is 0.1~60µm.

[0093] Preferably, in step S199, remelting is performed according to the cleanliness or purity of the required metal, and the remelting method is el...

Embodiment 3

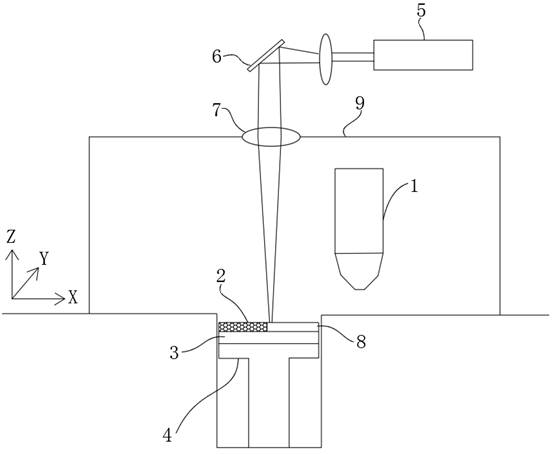

[0096] Such as Figure 5 As shown, the preparation method of a high-clean metal foil material described in this embodiment is roughly the same as that of embodiment 1 or embodiment 2, the difference is that based on the processing method of step S202; in an inert atmosphere or a reducing atmosphere Under the environment 9, the metal powder dispenser 1 moves along the X-axis or the X-Y axis to dispense a layer of metal powder on the substrate of the working platform, and the thickness of the dispensed metal powder layer is 1-300 μm. The laser plane scanner performs plane scanning and welding on the metal powder layer. When scanning, the laser energy is 50~500W, and the laser energy density is 10~350J / mm 3 , the scanning speed is 100~5000mm / sec, so that the metal powder layer 2 on the substrate is welded with the formed metal coarse foil 8 to form a continuous metal coarse foil, and the continuous metal foil is formed by welding one by one on the substrate The thick metal foils...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com