Colored tile paint and construction method

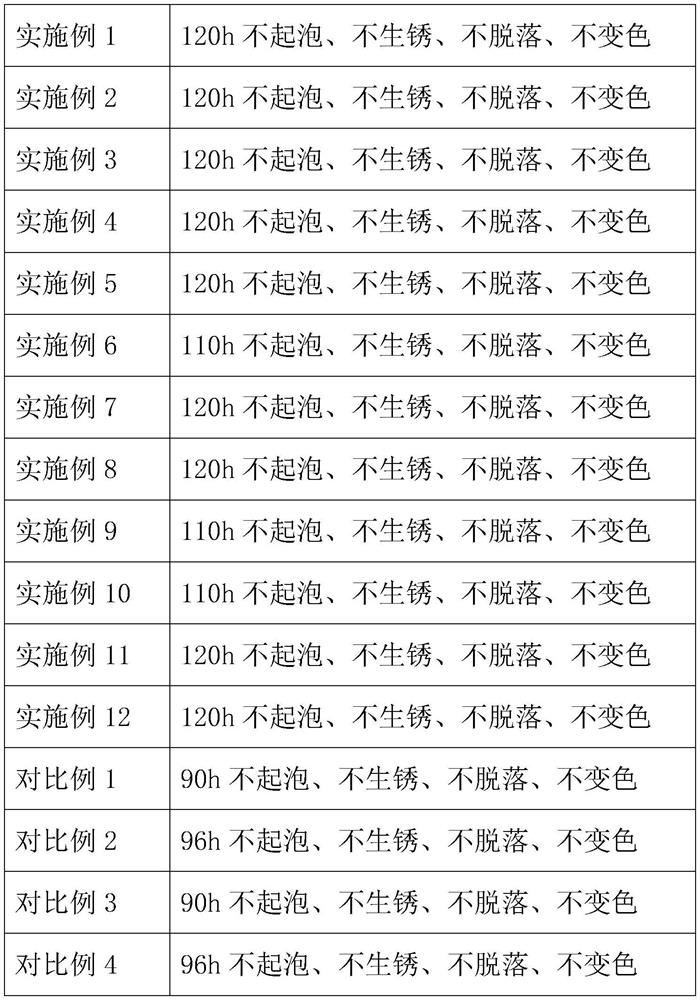

A color tile paint and raw material technology, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of product surface foaming, peeling, rust, etc., achieve good film-forming, high self-lubrication, good heat resistance and dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Caiwa paint includes the following raw materials: 15kg of titanium dioxide, 0.3kg of dioctyl sodium sulfosuccinate, 10kg of precipitated barium sulfate, 0.2kg of nonylphenol polyoxyethylene ether, 0.15kg of silane coupling agent KH560, multifunctional auxiliary Agent 0.1kg, silicone defoamer 0.1kg, fumed silica 0.8kg, butyl ether 0.3kg, leveling agent 0.2kg, ferrocene 2kg, performance modifier including alcohol ester twelve 2.5kg, acrylic emulsion 50kg, 0.5kg of polytetrafluoroethylene micropowder and 3kg of zinc phosphate, the thickener includes 1.5kg of pyrophyllite powder, 0.2kg of calcium chloride and 0.5kg of sodium silicate.

Embodiment 2

[0038] Caiwa paint includes the following raw materials: 23kg of titanium dioxide, 0.6kg of sodium dioctyl sulfosuccinate, 6kg of precipitated barium sulfate, 0.3kg of nonylphenol polyoxyethylene ether, 0.35kg of silane coupling agent KH560, multifunctional auxiliary Agent 0.2kg, silicone defoamer 0.3kg, fumed silica 0.4kg, butyl ether 0.7kg, leveling agent 0.2kg, ferrocene 4kg, performance modifier including alcohol ester twelve 2.5kg, acrylic emulsion 50kg, 0.5kg of polytetrafluoroethylene micropowder and 3kg of zinc phosphate, the thickener includes 1.5kg of pyrophyllite powder, 0.2kg of calcium chloride and 0.5kg of sodium silicate.

Embodiment 3

[0040] Caiwa paint includes the following raw materials: 17.5kg of titanium dioxide, 0.4kg of dioctyl sodium sulfosuccinate, 7.5kg of precipitated barium sulfate, 0.5kg of nonylphenol polyoxyethylene ether, 0.3kg of silane coupling agent KH560, and more Functional additive 0.2kg, organosilicon defoamer 0.2kg, fumed silica 0.5kg, butyl ether 0.4kg, leveling agent 0.3kg, ferrocene 2.8kg, performance modifier including alcohol ester twelve 2.5kg, acrylic acid Emulsion 50kg, polytetrafluoroethylene micropowder 0.5kg and zinc phosphate 3kg, thickener includes pyrophyllite powder 1.5kg, calcium chloride 0.2kg and sodium silicate 0.5kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com