Infiltrating type emulsifiable asphalt and preparation method thereof

An emulsified asphalt, soaking type technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of brittleness, poor temperature stability, and restrictions on the use of asphalt pavement, and achieve good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

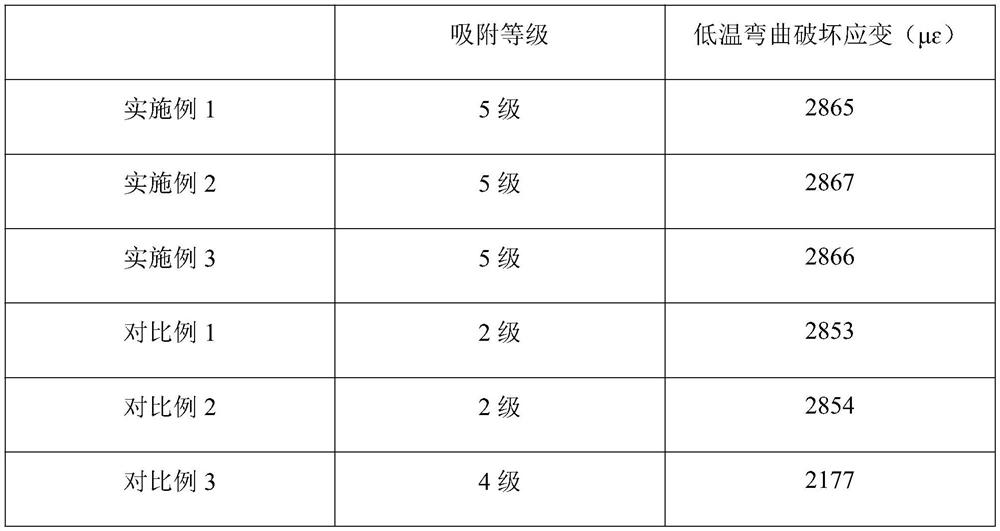

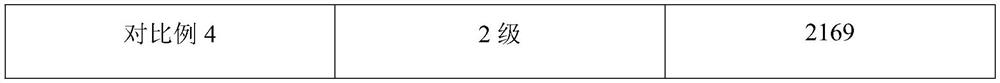

Examples

Embodiment 1

[0037] An infiltrating emulsifiable asphalt mainly includes, by weight, 100 parts of petroleum asphalt, 30 parts of magnetic nanosheets, 16 parts of modified silica sol, 0.6 parts of rubber operating oil, and 0.09 parts of sulfur.

[0038] A preparation method of soakable emulsifiable asphalt, the preparation method of said soakable emulsifiable asphalt mainly comprises the following preparation steps:

[0039] (1) Add tetraethyl orthosilicate, absolute ethanol, deionized water, and ammonia water with a mass fraction of 25% into a beaker at a mass ratio of 1:8.2:0.2:0.05, stir at 30°C and 100rpm for 3 hours, and then Aging for 6 days to obtain nano-silica sol;

[0040] (2) Add nano-silica sol into the container, add bis(triisopropylsilyl)amine with 0.25 times the mass of nano-silica sol, stir at 30°C and 200rpm for 3h, and age at room temperature for 6d to obtain Lipophilic nano silica sol;

[0041] (3) Add nano-silica sol into the container, add glycidoxypropyltrimethoxysil...

Embodiment 2

[0050] An infiltrating emulsifiable asphalt mainly includes, by weight, 160 parts of petroleum asphalt, 35 parts of magnetic nanosheets, 19 parts of modified silica sol, 1.05 parts of rubber operating oil, and 0.14 parts of sulfur.

[0051] A preparation method of soakable emulsifiable asphalt, the preparation method of said soakable emulsifiable asphalt mainly comprises the following preparation steps:

[0052] (1) Add tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water with a mass fraction of 26% in a beaker at a mass ratio of 1:8.41:0.24:0.057, stir at 30°C and 160rpm for 2.5h, and then Under aging for 7 days to obtain nano-silica sol;

[0053] (2) Add the nano-silica sol into the container, add bis(triisopropylsilyl)amine with 0.29 times the mass of the nano-silica sol, stir at 35°C and 250rpm for 2.5h, and age at room temperature for 6d, Obtain lipophilic nano silica sol;

[0054] (3) Add the nano-silica sol into the container, add glycidoxypro...

Embodiment 3

[0063] A wetting type emulsifiable asphalt mainly includes, by weight, 200 parts of petroleum asphalt, 40 parts of magnetic nanosheets, 22 parts of modified silica sol, 2 parts of rubber operating oil, and 0.2 parts of sulfur.

[0064] A preparation method of soakable emulsifiable asphalt, the preparation method of said soakable emulsifiable asphalt mainly comprises the following preparation steps:

[0065](1) Add tetraethyl orthosilicate, absolute ethanol, deionized water and ammonia water with a mass fraction of 28% into a beaker at a mass ratio of 1:8.7:0.3:0.06, stir at 30°C and 200rpm for 2 hours, and then Aging for 7 days to obtain nano-silica sol;

[0066] (2) Add nano-silica sol into the container, add bis(triisopropylsilyl)amine with 0.33 times the mass of nano-silica sol, stir at 40°C and 300rpm for 2h, and age at room temperature for 7d to obtain Lipophilic nano silica sol;

[0067] (3) Put the nano-silica sol into the container, add glycidoxypropyltrimethoxysilan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com