Nickel-saving high-strength stainless steel raw material composition

A raw material composition, stainless steel technology, applied in the field of stainless steel manufacturing, can solve the problem of low mineral reserves, etc., achieve strong corrosion resistance, strong antibacterial properties, and avoid the effects of deoxidizer residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

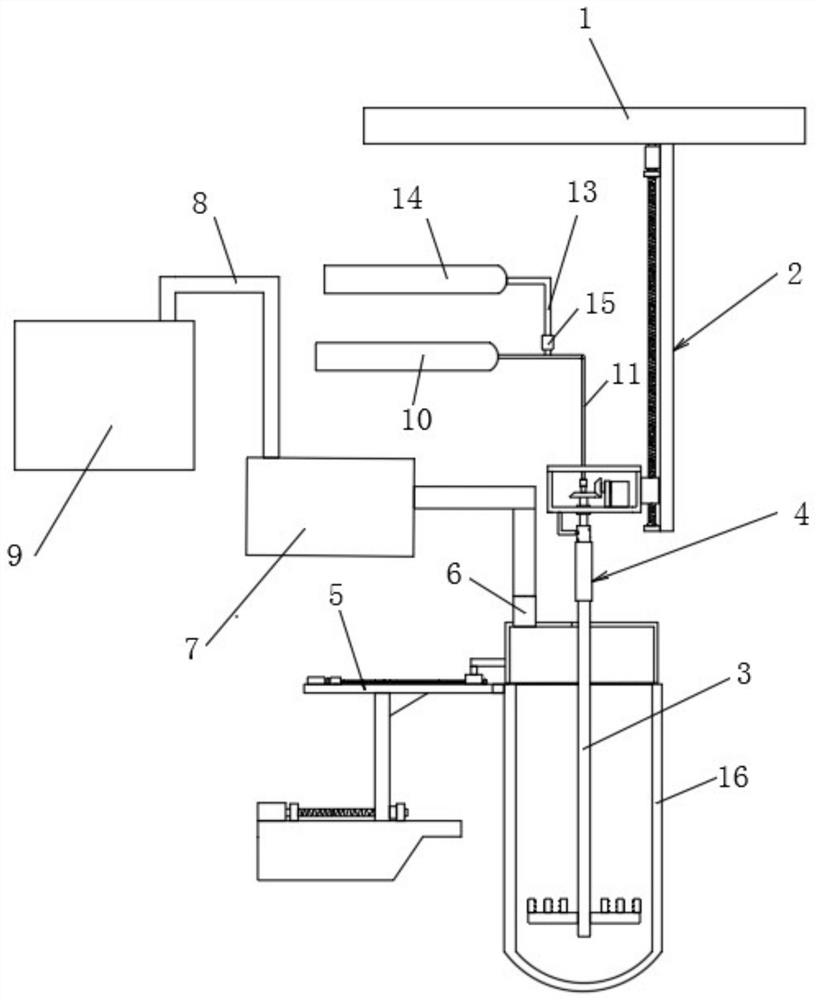

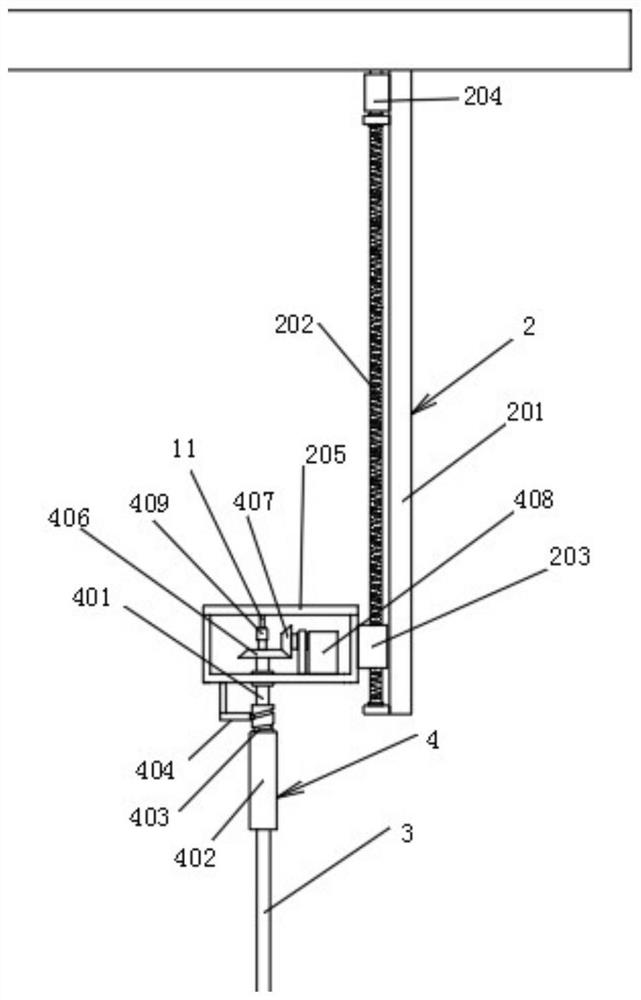

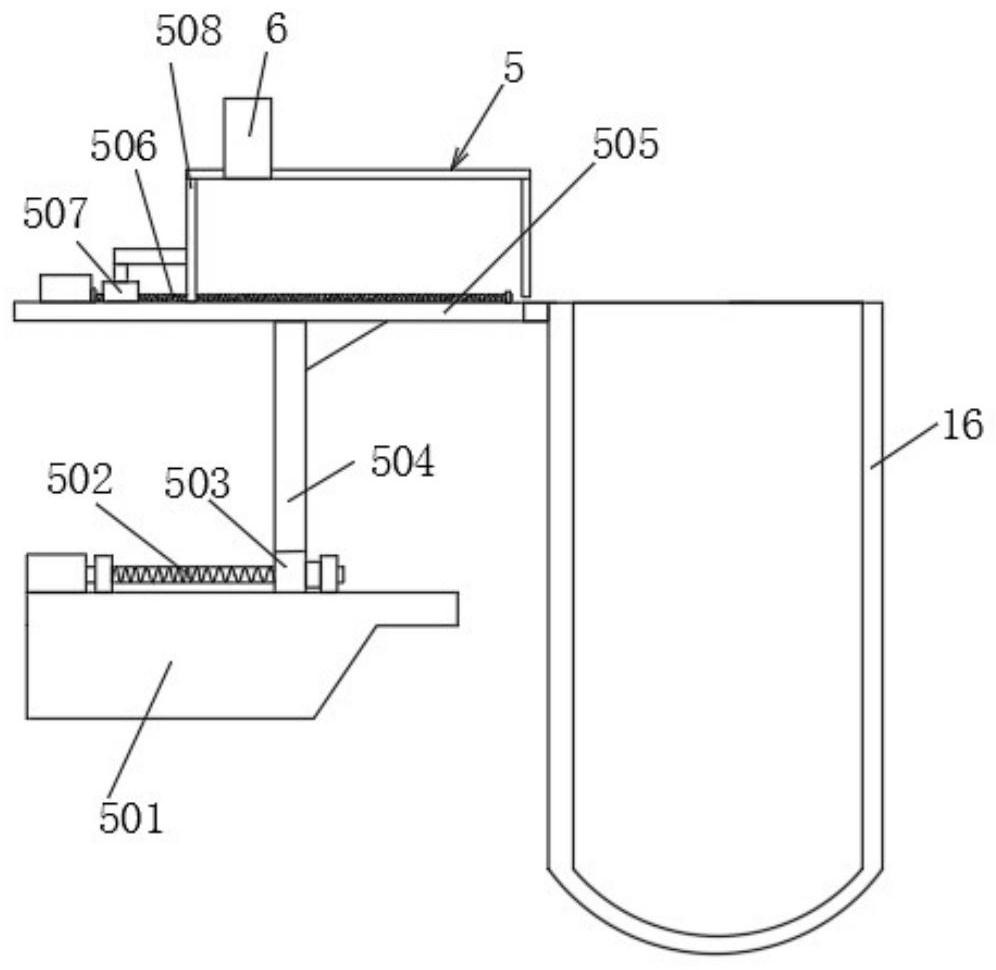

[0041] Example: such as Figure 1-9 As shown, a nickel-saving high-strength stainless steel raw material composition of the present invention, the components of the stainless steel raw material composition and the weight percentage of each component are: carbon content≦0.15%, silicon content≦1%, manganese content 4%- 8%, chromium content 17.5%-21%, nickel content 2.0%-4.5%, copper content 1.0%-4%, nitrogen content 0.2%-0.35%, molybdenum content ≦ 0.4%, others are combinations of iron content;

[0042] It also includes a smelting process for a nickel-saving high-strength stainless steel raw material composition, which specifically includes the following steps,

[0043] Step 1: Check the melting furnace before starting the furnace, and carry out quantitative weighing according to the weight percentage of each component;

[0044] Step 2: first smelt the basic molten steel, then put the quantitatively weighed mixture of carbon, silicon, chromium, nitrogen, copper, nickel and an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com