Aluminum alloy radiator and preparation method thereof

An aluminum alloy and heat sink technology, applied in the field of aluminum alloy heat sink and its preparation, can solve the problems of unfavorable human body and large environmental pollution, etc., and achieve the effects of good salt water immersion resistance, good adhesion, and good boiling water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

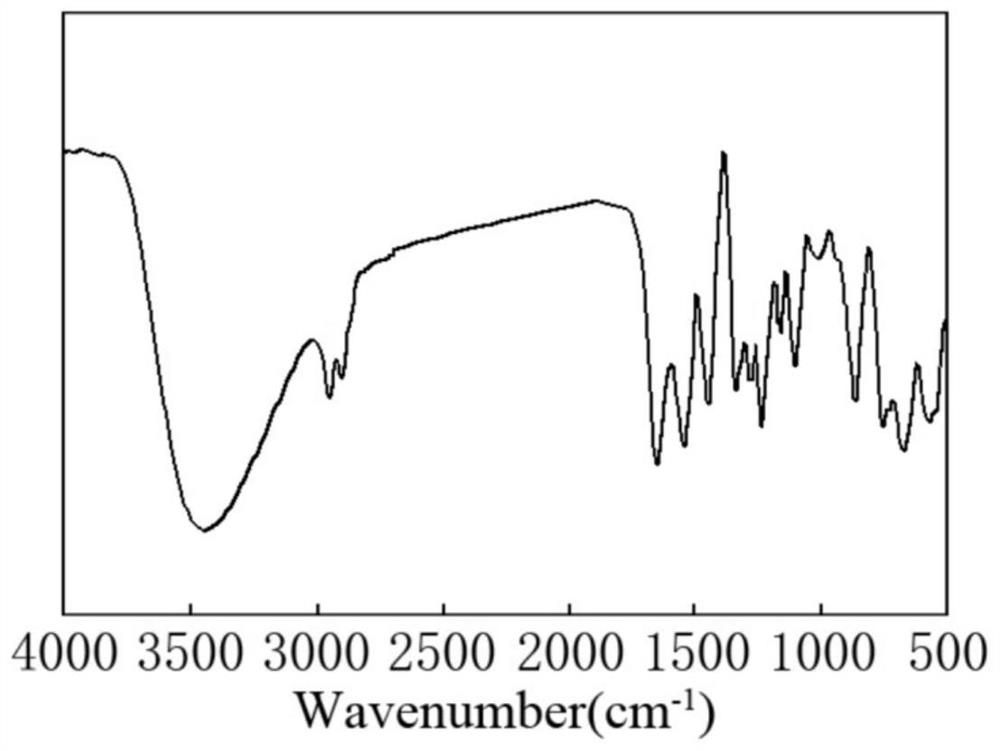

Image

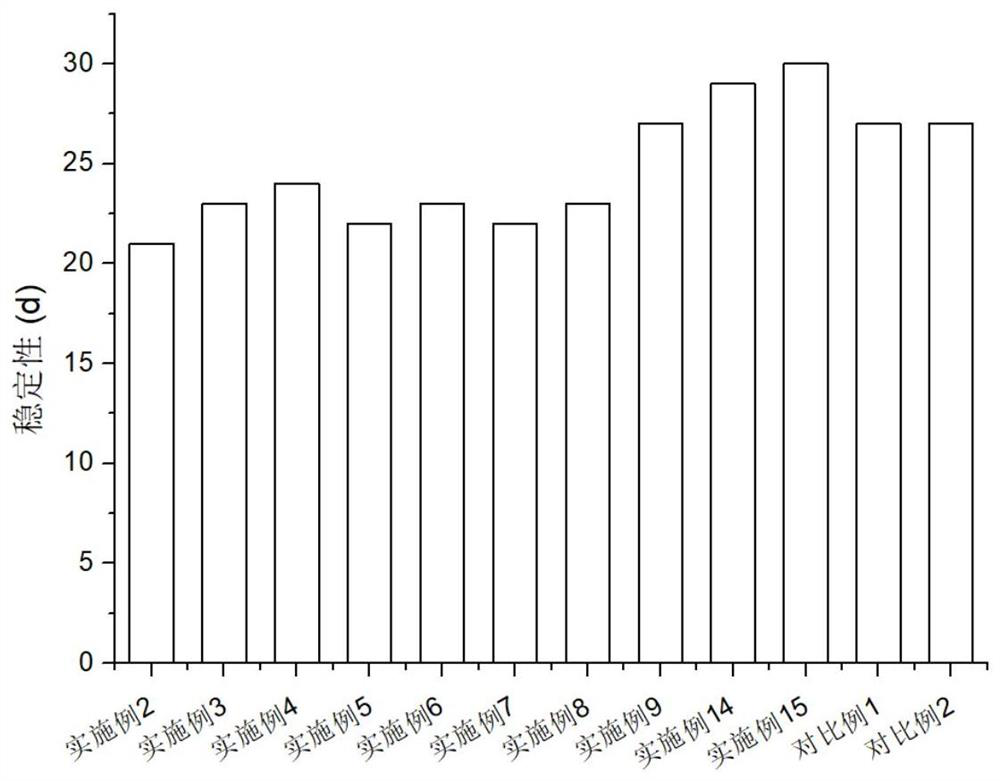

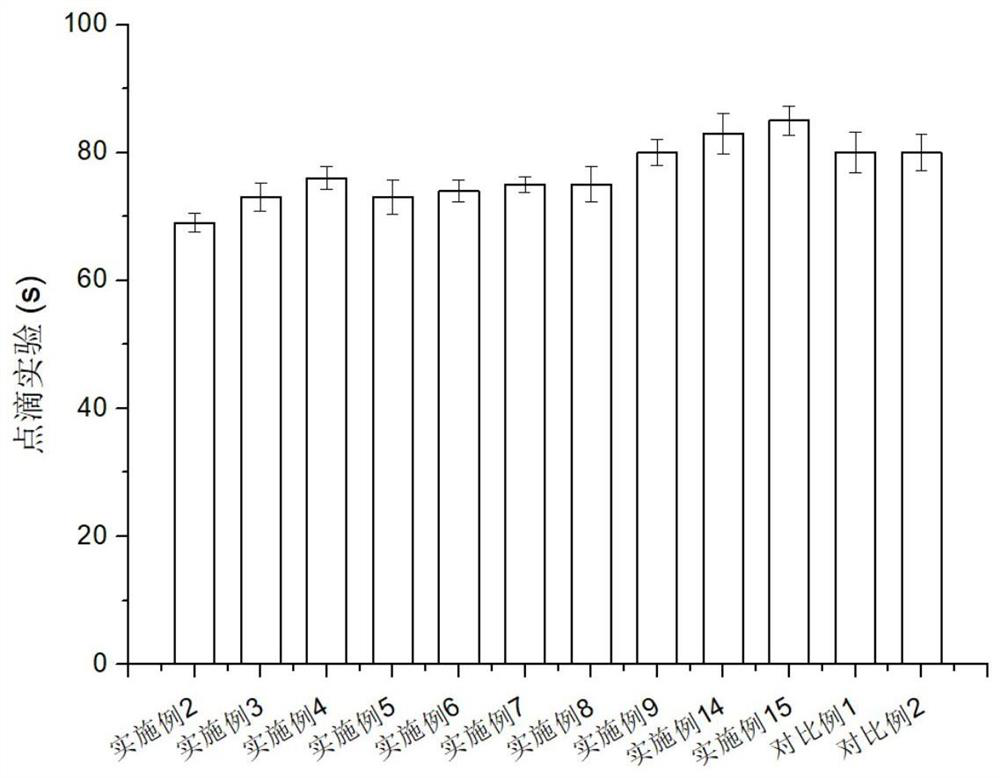

Examples

Embodiment 1

[0044] A preparation method of Mancini base compound,

[0045] Preparation of Mancini base compound: add formaldehyde and 2-amino-1-butanol to the solvent, react at a temperature of 25°C for 1h, then add catechol dropwise, react at a temperature of 35°C for 9h, spin Mancini base compound is obtained after steaming treatment; solvent is dehydrated alcohol, and the addition amount of formaldehyde is 6wt% of solvent, and the addition amount of 2-amino-1-butanol is 12wt% of solvent, and the addition amount of pyrocatechol It is 8wt% of the solvent.

Embodiment 2

[0047] A preparation method of an aluminum alloy radiator with a protective film attached,

[0048] Preparation of the metal complex: add a metal reagent to the Mancini base compound prepared in Example 1, and stir at 25° C. for 1 h to obtain a titanium complex. The metal reagent is fluotitanic acid, and the added amount of the metal reagent is 2.1wt% of absolute ethanol.

[0049] Surface pretreatment of aluminum alloy radiator profiles: immerse aluminum alloy radiator profiles in degreasing agent, remove oil at 60°C for 5 minutes, then immerse in alkaline cleaning solution, treat at 60°C for 10 minutes, then Immerse in pickling solution and treat at 30°C for 10 minutes to obtain a pretreated aluminum alloy radiator profile. The degreasing agent is an aqueous solution containing sodium bicarbonate, acetone and sodium dodecylbenzenesulfonate, containing 5wt% sodium bicarbonate in the degreasing agent, containing 0.8wt% acetone in the degreasing agent, containing The sodium do...

Embodiment 3

[0053] Compared with Example 2, this example differs only in that the content of the metal complex in the conversion solution is 1.5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com