Nitrogen-doped graphene-metal nanoparticle film and preparation method thereof

A metal nanoparticle, nitrogen-doped graphene technology, applied in graphene, metal processing equipment, nano-carbon and other directions, can solve the limitations of large-scale, continuous preparation of graphene films, difficult to disperse, coordinate and solidify, impossible Solidification molding and other problems, to achieve the effect of good strength and toughness, simple operation, excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of graphene oxide solution:

[0043]10g of graphite, 150ml of 98% sulfuric acid, 30ml of 69% nitric acid were added to a 500ml Erlenmeyer flask and stirred at room temperature for 24 hours, slowly poured into 1L of water to collect the solid, washed 3 times, and dried at 80°C for 4 hours to obtain pre-oxidized graphite. Repeat the pre-oxidation process twice. Put the dried pre-oxidized graphite into a box furnace to thermally expand at 950°C for 20s to obtain thermally expanded graphite oxide. Mix 5g of heat-expandable graphite oxide with 300ml of sulfuric acid (concentration 98%), 5g of potassium persulfate, and 7g of phosphorus pentoxide in a 500ml wide-mouth conical flask, heat at 80°C for 4 hours, dilute with 2L of water, filter and wash, and air Dry for 3 days to obtain pre-oxidized heat-expandable graphite. Mix dry pre-oxidized heat-expandable graphite with 200ml sulfuric acid (concentration 98%) at a low temperature of 0-5°C, add 20g pota...

Embodiment 2

[0046] The preparation method of graphene oxide solution is as embodiment 1.

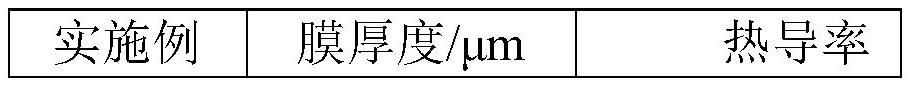

[0047] Mix the graphene oxide solution, platinum nanoparticles with a particle size of 20-50nm, and ethylenediamine to obtain a mixture (slurry), wherein the content of graphene oxide is 1mg / mL mixture, graphene oxide and platinum nanoparticles The mass ratio of ethylenediamine is 1:0.1, and the mass fraction of ethylenediamine relative to the mixture is 20%. The mixture is coated into a film, dried at 85°C for 4h to obtain an amine-based cross-linked graphene oxide-metal nanoparticle film, and then heat-treated to obtain a nitrogen-doped graphene-metal nanoparticle film (heat treatment temperature is 2000°C, time is 3h) , and finally the nitrogen-doped graphene-metal nanoparticle film is calendered to obtain a nitrogen-doped graphene-metal nanoparticle film with high thermal conductivity. The thickness and thermal conductivity of the resulting highly thermally conductive nitrogen-doped graphene-me...

Embodiment 3

[0049] The preparation method of graphene oxide solution is as embodiment 1.

[0050] A mixture of graphene oxide solution, silver nanoparticles and lead nanoparticles with a particle size of 100-200nm (the mass ratio of silver nanoparticles and lead nanoparticles is 1:1), ammonia and triethylenetetramine is uniformly mixed to obtain a mixture (slurry), wherein, the content of graphene oxide is 80mg / mL mixture, the mass ratio of graphene oxide and metal nanoparticles total amount is 1:1, and the mass fraction of ammonia relative to the mixture is 30%, triethylenetetramine The mass fraction relative to the mixture is 5%. The mixture is coated into a film, dried at 75°C for 8 hours to obtain an amine-based cross-linked graphene oxide-metal nanoparticle film, and then heat-treated to obtain a nitrogen-doped graphene-metal nanoparticle film (heat treatment temperature is 1500°C, time is 4h) , and finally the nitrogen-doped graphene-metal nanoparticle film is calendered to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com