Copper-vanadium-based gas shielded welding wire for transition layer of titanium-steel composite structure and preparation method of copper-vanadium-based gas shielded welding wire

A composite structure and transition layer technology, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of high content of brittle compounds between metals, weld cracks, etc., and achieve low cost, good welding process, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

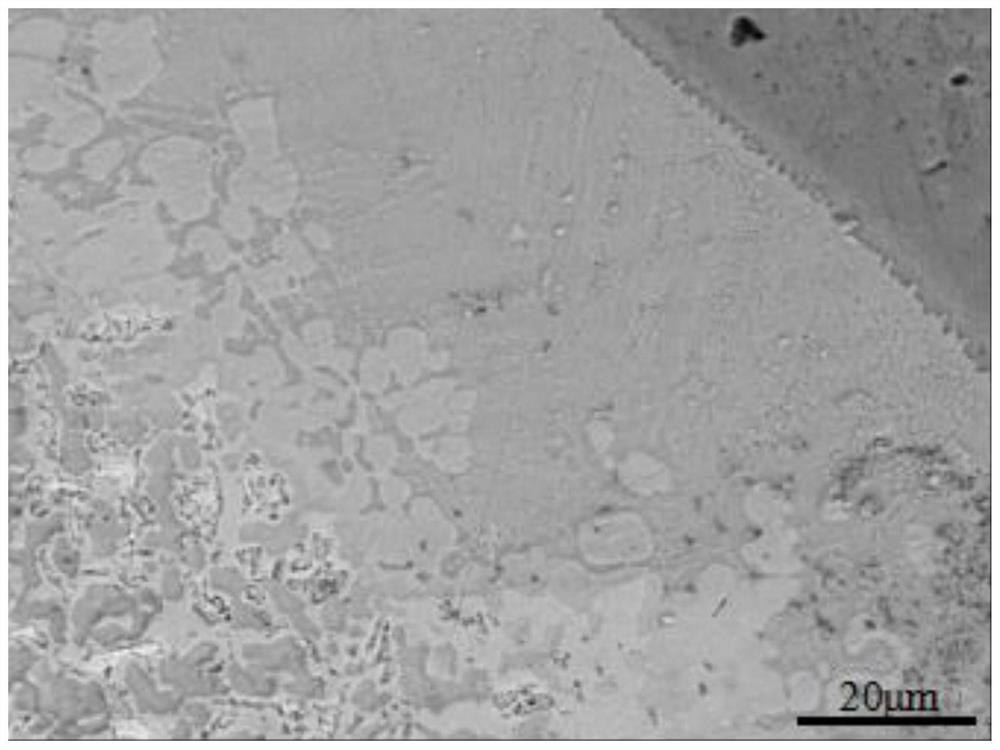

Image

Examples

preparation example Construction

[0036] A method for preparing a copper-vanadium-based gas-shielded welding wire for a transition layer of a titanium-steel composite structure comprises the following steps:

[0037] Step 1. Weighing the raw materials according to mass percentage: V30%-50%, Ni2%-5%, Ag1%-4%, Nb2%-5%, P≤0.003%, S≤0.003%, rare earth element 1% , the rest is copper powder, the sum of the mass percentages of the above components is 100%; the above raw materials are all powder, and the particle size of the powder is not greater than 124 μm;

[0038] Step 2, heating the raw material in step 1 in an argon atmosphere and keeping it warm, the heating temperature is 100°C-300°C, and the holding time is 1h-3h.

[0039] Step 3. Mix the raw materials processed in step 2 in a mixer, and then add a binder for granulation to obtain particles with a particle size of 124 μm to 420 μm; the mass ratio of the binder to the mixed raw materials is 4:72 to 6:120, the binder can be potassium sodium water glass;

[0...

Embodiment 1

[0045] Step 1. Weigh raw materials according to mass percentage: V30%, Ni2%, Ag1%, Nb2%, P0.003%, S0.003%, and the rest is copper powder. The sum of the mass percentages of the above components is 100% ;

[0046] Step 2, heating the raw material in step 1 in an argon atmosphere and keeping it warm, the heating temperature is 200°C, and the keeping time is 2h;

[0047] Step 3. Mix the raw materials processed in step 2 in a mixer, and then add a binder for granulation to obtain particles with a particle size of 270 μm; the mass ratio of the binder to the mixed raw materials is 5:95, and the binder Potassium sodium water glass can be used;

[0048]Step 4, sintering the particles at 700°C and keeping them warm for 2 hours, then cooling, crushing, and finally sieving to obtain 200 μm powder particles;

[0049] Step 5. Wrap the drug powder particles in the copper tape through the flux-cored wire making machine, and use the forming machine to close the copper tape to obtain the sem...

Embodiment 2

[0053] Step 1. Weigh raw materials according to mass percentage: V35%, Ni3%, Ag2%, Nb3%, P0.003%, S0.003%, the rest is copper powder, and the sum of the mass percentages of the above components is 100% ;

[0054] Step 2. Heat the raw material in step 1 in an argon atmosphere and keep it warm. The heating temperature is 200° C. and the holding time is 2 hours.

[0055] Step 3. Mix the raw materials processed in step 2 in a mixer, and then add a binder for granulation to obtain particles with a particle size of 270 μm; the mass ratio of the binder to the mixed raw materials is 5:95, and the binder Potassium sodium water glass can be used;

[0056] Step 4, sintering the particles at 700°C and keeping them warm for 2 hours, then cooling, crushing, and finally sieving to obtain 200 μm powder particles;

[0057] Step 5. Wrap the drug powder particles in the copper tape through the flux-cored wire making machine, and use the forming machine to close the copper tape to obtain the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com