Preparation process of multi-component spherical alloy powder

A technology of alloy powder and preparation process, which is applied in the field of metal powder processing, can solve the problems of difficulty in smelting and bar making, high melting point hardness, and brittle fracture, etc., and achieve the effects of high sphericity, high tap density and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: A preparation process of multi-component spherical alloy powder, using the PREP method to prepare multi-component spherical alloy powder, the multi-component alloy includes at least one of refractory metals and their compounds, specifically including tungsten and molybdenum , tantalum, niobium, rhenium, tungsten carbide, tantalum carbide, etc.

[0043] Its concrete preparation method is:

[0044] 2.1 Prepare multi-component alloy rods;

[0045] 2.2 Use the alloy rod in step 2.1 to prepare multi-component spherical alloy powder by the PREP method.

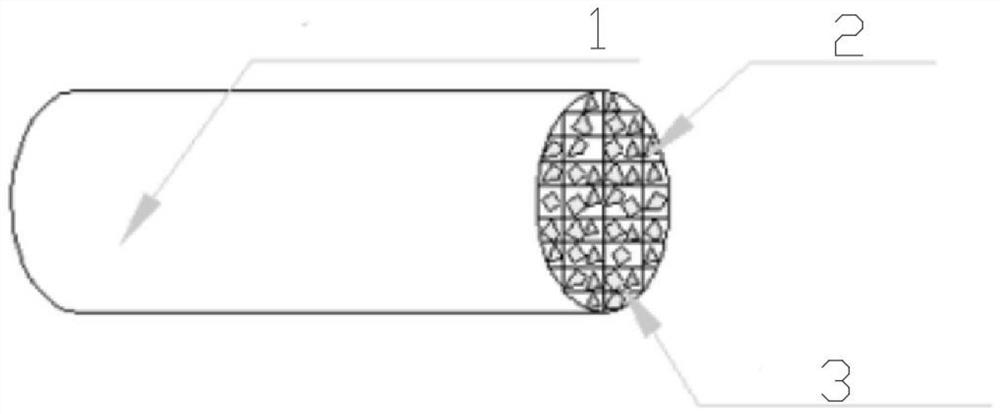

[0046] In this embodiment, the spatial structure weaving method is used to prepare multi-component alloy rods, and the specific preparation method is as follows:

[0047]3.1 Design the size and structure of the mesh according to the size and shape of the refractory metal or its compound, and use the metal components that are easy to weave in the multi-components to make wires and weave the mesh to form a metal me...

Embodiment 2

[0052] Example 2: A preparation process for a multi-component spherical alloy powder, using the PREP method to prepare a multi-component spherical alloy, the multi-component includes at least one of refractory metals and their compounds, specifically including tungsten, molybdenum, and tantalum , niobium, rhenium, tungsten carbide, tantalum carbide, etc. Its concrete preparation method is:

[0053] 2.1 Prepare multi-component alloy rods;

[0054] 2.2 Use the alloy rod in step 2.1 to prepare multi-component spherical alloy powder by the PREP method.

[0055] In this embodiment, a multi-component alloy rod is prepared by direct mixing of elements, and the specific preparation method is as follows:

[0056] 4.1 Do the powder batching according to the element ratio of the target multi-component alloy, and then use a planetary high-energy ball mill for mechanical ball milling. During the ball milling process, use argon protection to prevent the powder from being oxidized during t...

Embodiment 3

[0064] Example 3: A preparation process for a multi-component spherical alloy powder, using the PREP method to prepare a multi-component spherical alloy, the multi-component includes at least one of refractory metals and their compounds, specifically including tungsten, molybdenum, and tantalum , niobium, rhenium, tungsten carbide, tantalum carbide, etc. Its concrete preparation method is:

[0065] 2.1 Prepare multi-component alloy rods;

[0066] 2.2 Use the alloy rod in step 2.1 to prepare multi-component spherical alloy powder by the PREP method.

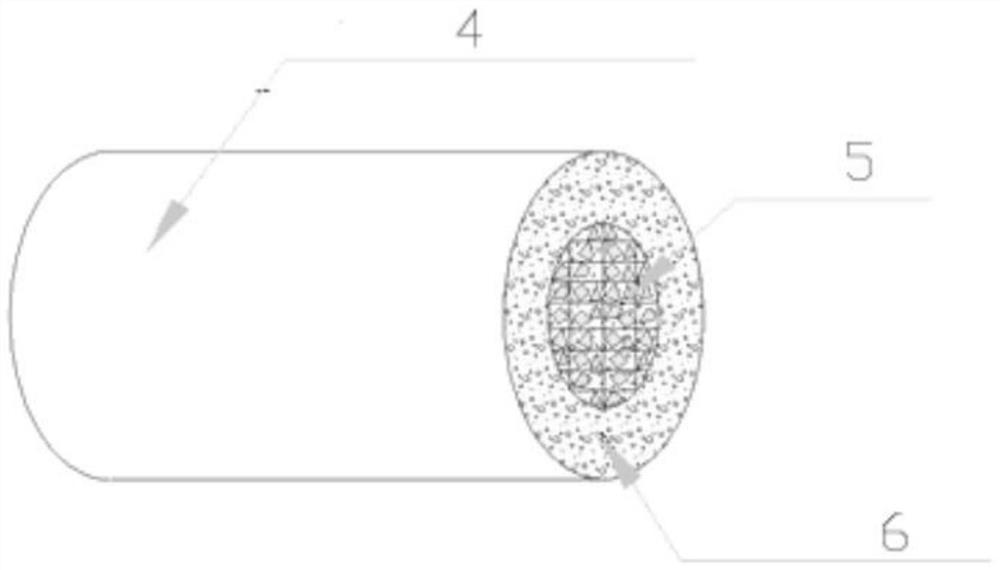

[0067] In this embodiment, the porous skeleton method is used to prepare multi-component alloy rods, and the specific preparation method is as follows:

[0068] 7.1 Use refractory metals or hard alloys with large particle sizes as raw materials, mix them with spherical pore-forming agents and put them into a mixer for mixing; the pore-forming agents are stearic acid or urea.

[0069] In this step, a spherical pore-forming agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com