Carbon fiber reinforced resin-based composite material interface microcell structure regulation and control method

A technology for reinforcing resin-based and composite materials, applied in the field of composite materials, can solve problems such as unstable treatment effects, and achieve stable treatment effects, uniform distribution, and strong pinning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

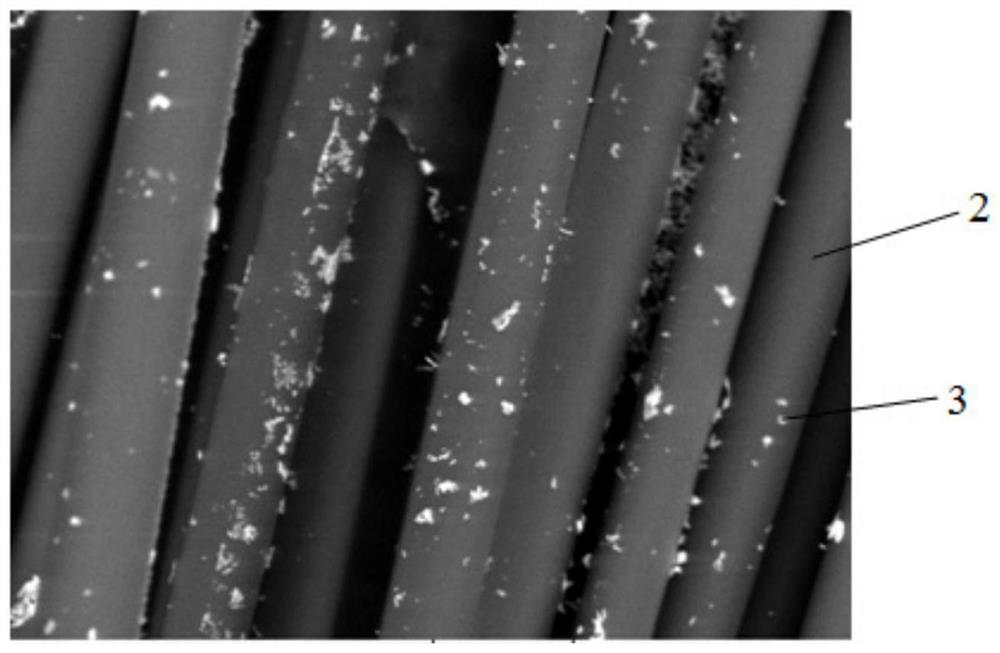

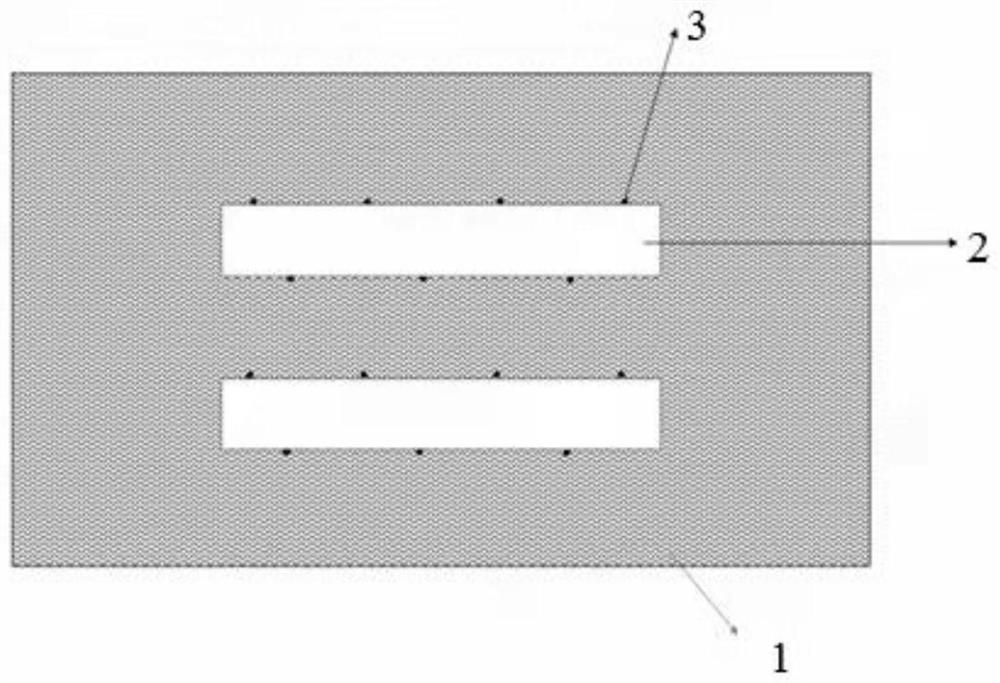

[0030] A carbon fiber-reinforced resin-based composite material interface micro-domain structure control method, comprising the following steps:

[0031] Step 1. Toray T700 chopped carbon fibers with a diameter of 6 μm to 7 μm and a length of 1 mm to 3 mm are placed in a Soxhlet extractor together with an organic solvent for extraction to remove sizing agents and impurities on the surface of the carbon fiber; the extraction temperature is 80 ° C, and the extraction The time is 24 hours. The organic solvent is made by mixing ethanol, acetone and tetrahydrofuran with a volume ratio of 1:1:1; then the extract is soaked in ethanol solution and aqueous solution for 10 minutes, and finally dried at 80°C to obtain a clean surface. carbon fiber;

[0032] Step 2, put the pure niobium target into the multi-arc ion plating head, as the cathode, the target purity is 99.9%; install the pretreated carbon fiber on the turntable in the vacuum chamber, and evacuate the vacuum chamber to 4×10 ...

Embodiment 2

[0037] A carbon fiber-reinforced resin-based composite material interface micro-domain structure control method, comprising the following steps:

[0038] Step 1. Put Toray T700 chopped carbon fibers with a diameter of 6 μm to 7 μm and a length of 3 mm to 5 mm together with an organic solvent for extraction in a Soxhlet extractor to remove sizing agents and impurities on the surface of the carbon fibers; the extraction temperature is 70 ° C, and the extraction The time is 15 hours. The organic solvent is made by mixing ethanol, acetone and tetrahydrofuran with a volume ratio of 1:5:5; then the extract is soaked in ethanol solution and aqueous solution for 5 minutes, and finally dried at 80°C to obtain a clean surface. carbon fiber;

[0039] Step 2, put the pure titanium target into the multi-arc ion plating arc head, as the cathode, the target purity is 99.9%; install the pretreated carbon fiber on the turntable in the vacuum chamber, and evacuate the vacuum chamber to 3×10 -...

Embodiment 3

[0044] A carbon fiber-reinforced resin-based composite material interface micro-domain structure control method, comprising the following steps:

[0045] Step 1. Toray T700 chopped carbon fibers with a diameter of 6 μm to 7 μm and a length of 4 mm to 6 mm are placed in a Soxhlet extractor together with an organic solvent for extraction to remove sizing agents and impurities on the surface of the carbon fiber; the extraction temperature is 50 ° C, and the extraction The time is 18 hours. The organic solvent is made by mixing ethanol, acetone and tetrahydrofuran with a volume ratio of 1:2:3; then the extract is soaked in ethanol solution and aqueous solution for 8 minutes, and finally dried at 80°C to obtain a clean surface. carbon fiber;

[0046] Step 2, put the pure tantalum target into the multi-arc ion plating arc head, as the cathode, the target purity is 99.9%; install the pretreated carbon fiber on the turntable in the vacuum chamber, and evacuate the vacuum chamber to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com