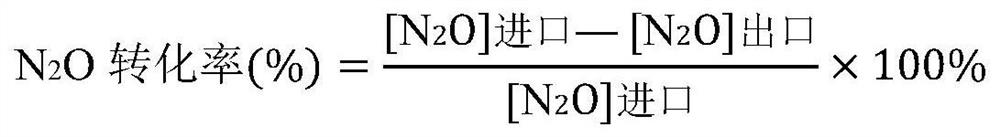

Metal forming catalyst for decomposing N2O and preparation method thereof

A technology of metal forming and catalyst, which is applied in the direction of catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc. It can solve the problems of high catalyst requirements and decreased nitric acid yield, achieve good plasticity, increase production energy consumption, The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of Fe / SSZ-16 molding catalyst, is made up of following raw material:

[0051] Molecular sieve carrier: SSZ-16, 75 parts by weight;

[0052] Metal single atom: Fe, 1.923 parts by weight;

[0053] Binder: pseudo-boehmite powder, 25 parts by weight;

[0054] Extrusion aid: tianjing powder, 3 parts by weight;

[0055] Peptizer: nitric acid, 10 parts by weight;

[0056] The steps of preparation are as follows:

[0057] S1-1: High temperature calcination:

[0058] Put 200g of SSZ-16 molecular sieve in an evaporating dish, place it in a muffle furnace and heat it from room temperature to 540°C at a heating rate of 2°C / min, then calcine at a constant temperature for 6 hours and then naturally drop to room temperature;

[0059] S1-2: Pulverization:

[0060] The SSZ-16 molecular sieve calcined at high temperature is pulverized, then sieved, and the particle size is controlled to 150 mesh, and the sieved SSZ-16 molecular sieve is obtained;

[0061] S1-3: Dry mixing, ...

Embodiment 2

[0070] A Cu / RUB-50 shaped catalyst consists of the following raw materials:

[0071] Molecular sieve carrier: RUB-50, 80 parts by weight;

[0072] Metal single atom: Cu, 1.633 parts by weight;

[0073] Binder: pseudo-boehmite powder, 20 parts by weight;

[0074] Extrusion aid: tianjing powder, 2.5 parts by weight;

[0075] Peptizer: nitric acid, 10 parts by weight;

[0076] The steps of preparation are as follows:

[0077] S1-1: High temperature calcination:

[0078] Put 200g of RUB-50 molecular sieve in an evaporating dish, place it in a muffle furnace, heat it from room temperature to 540°C at a heating rate of 2°C / min, and then calcine at a constant temperature for 6 hours, then naturally drop to room temperature;

[0079] S1-2: Pulverization:

[0080] The RUB-50 molecular sieve calcined at high temperature is pulverized, and then sieved, the particle size is controlled to 150 mesh, and the sieved RUB-50 molecular sieve is obtained;

[0081] S1-3: Dry mixing, kneadin...

Embodiment 3

[0090] A Fe and Cu / SSZ-39 shaped catalyst consisting of the following raw materials:

[0091] Molecular sieve carrier: SSZ-39, 70 parts by weight;

[0092] Metal single atom: Fe and Cu, both 1.066 parts by weight;

[0093] Binder: pseudo-boehmite powder, 30 parts by weight;

[0094] Extrusion aid: tianjing powder, 3.5 parts by weight;

[0095] Peptizer: nitric acid, 13 parts by weight;

[0096] The steps of preparation are as follows:

[0097] S1-1: High temperature calcination:

[0098] Put 200g of SSZ-39 molecular sieve in an evaporating dish, place it in a muffle furnace, heat it from room temperature to 540°C at a heating rate of 2°C / min, and then calcine at a constant temperature for 6 hours, then naturally drop to room temperature;

[0099] S1-2: Pulverization:

[0100] The SSZ-39 molecular sieve calcined at high temperature is pulverized, then sieved, and the particle size is controlled to 150 mesh to obtain the sieved SSZ-39 molecular sieve;

[0101] S1-3: Dry m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com