A kind of nickel-based superalloy powder and preparation method applied to hollow turbine blade

A nickel-based high-temperature alloy and turbine blade technology, applied in the field of additive manufacturing, can solve the problems of poor corrosion resistance of hollow turbine blades, and achieve the effects of overcoming cracks, suppressing crack generation, and delaying crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

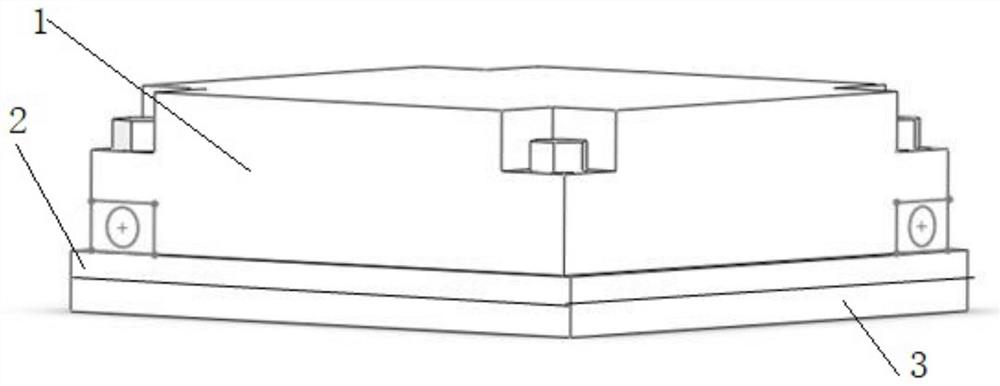

Image

Examples

Embodiment 1

[0036] (1) A nickel-based superalloy powder, the alloy composition is as follows: 25%Cr, 17.5% Co, 2.5% Al, 2.3% Ta, 2.6% Ti, 1.7%W, 1.5%Re, 0.1%C, 0.8% Cb, 0.2% Zr, 0.005% B, 0.5% V, and the residual amount is Ni for batching.

[0037] (2) The preparation of nickel-based superalloy powder containing the above alloy components, the specific steps are as follows:

[0038]The prepared alloy is first melted in a vacuum induction furnace, and then remelted in a vacuum self-consuming furnace to obtain a parent alloy ingot with a diameter of 80mm. The mother alloy ingot is put into a high-temperature box resistance furnace, heat treated at a temperature of 1250 ° C for 20h, so that its composition is uniform, and then cooled to room temperature with the furnace, the cooled mother alloy ingot is machined into an electrode rod, the diameter of the electrode rod is 80mm, and the length is 680mm. Through the plasma rotary electrode mill, vacuum filling argon, adjust the power of the plasma ...

Embodiment 2

[0044] (1) A nickel-based superalloy powder, the alloy composition is as follows: 30%Cr, 19% Co, 3.0% Al, 2.5% Ta, 2.8% Ti, 2.1% W, 2.5% Re, 0.15% C, 1% Cb, 0.3% Zr, 0.01% B, 0.7% V, the margin is Ni.

[0045] (2) The preparation method of nickel-based superalloy powder containing the above alloy components is the same as Example 1.

[0046] (3) The use of nickel-based superalloy powder of the above alloy composition to prepare hollow turbine blades, the specific steps are as follows:

[0047]Step 1: Take zirconia powder mixed with 5w% single crystal sapphire fiber, and prepare the composite material by plasma sintering method, where the sintering temperature is 1100 °C, the sintering pressure is 30Mpa, and the sintering time is 10h, and the zirconia / alumina fiber composite material is obtained. The zirconia / alumina fiber composite is placed in a high-energy ball mill for ball milling. The speed of the ball mill is set to 300rpm / min, the ball milling time is 10h, and the ball-to-m...

Embodiment 3

[0051] (1) A nickel-based superalloy powder, the alloy composition is as follows: 27.5% Cr, 18% Co, 2.7% Al, 2.4% Ta, 2.7% Ti, 1.9% W, 2.0% Re, 0.15% C, 0.9% Cb, 0.25% Zr, 0.01% B, 0.6% V, the margin is Ni.

[0052] (2) The preparation method of nickel-based superalloy powder containing the above alloy components is the same as Example 1.

[0053] (3) The use of nickel-based superalloy powder of the above alloy composition to prepare hollow turbine blades, the specific steps are as follows:

[0054] Step 1: Take zirconia powder mixed with 5w% single crystal sapphire fiber, and prepare the composite material by plasma sintering method, where the sintering temperature is 1400 °C, the sintering pressure is 70Mpa, and the sintering time is 13h, and the zirconia / alumina fiber composite material is obtained. The zirconia / alumina fiber composite is placed in a high-energy ball mill for ball milling. The speed of the ball mill is set to 300rpm / min, the ball milling time is 15h, and the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com