Preparation method of graphene-based lithium iron phosphate positive electrode material

A technology of alkenyl iron phosphate lithium and positive electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of reducing the mass of effective active materials, affecting the diffusion of lithium ions, and uneven morphology, so as to achieve improved Dispersion and uniformity, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

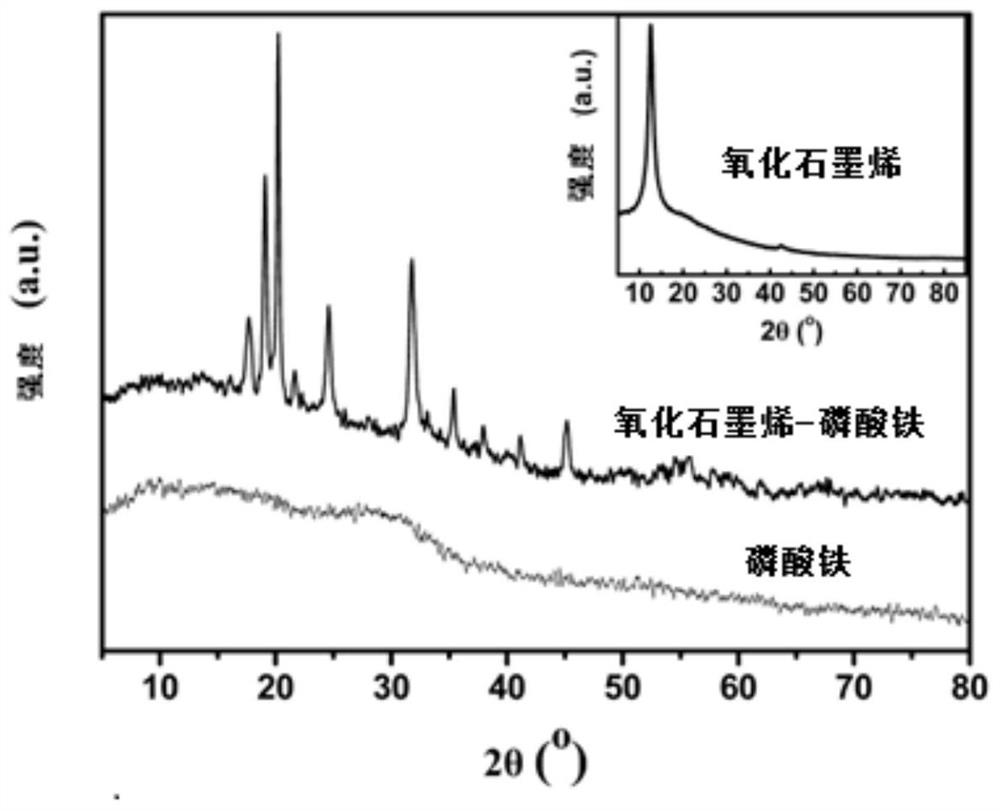

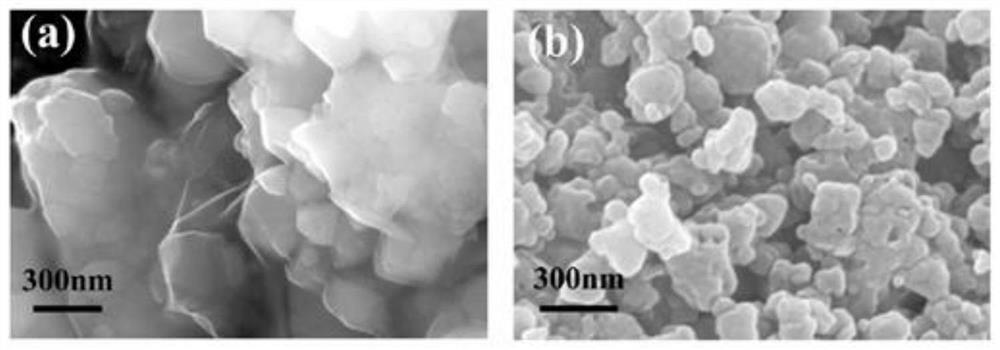

[0036] Weigh ferrous sulfate heptahydrate to dissolve and be mixed with a solution, then add graphene oxide slurry and stir evenly, the amount of graphene oxide added is 5% of the produced ferric phosphate quality, and the molar ratio of Fe:P is 1:1.1 before stirring Add ammonium hydrogen phosphate solution under the condition of stirring, adjust the pH to 2.0-2.5 with ammonia water, then add surfactant OP-10 (non-ionic surfactant alkylphenol polyoxyethylene ether) and add hydrogen peroxide under the condition of stirring, at 70- Iron phosphate was precipitated by reaction at 80°C. The resulting iron phosphate was washed with water, filtered, and vacuum-dried at 100°C. The dried sample was calcined at 500°C for 4 hours, cooled and ground to form a graphene oxide-iron phosphate composite material.

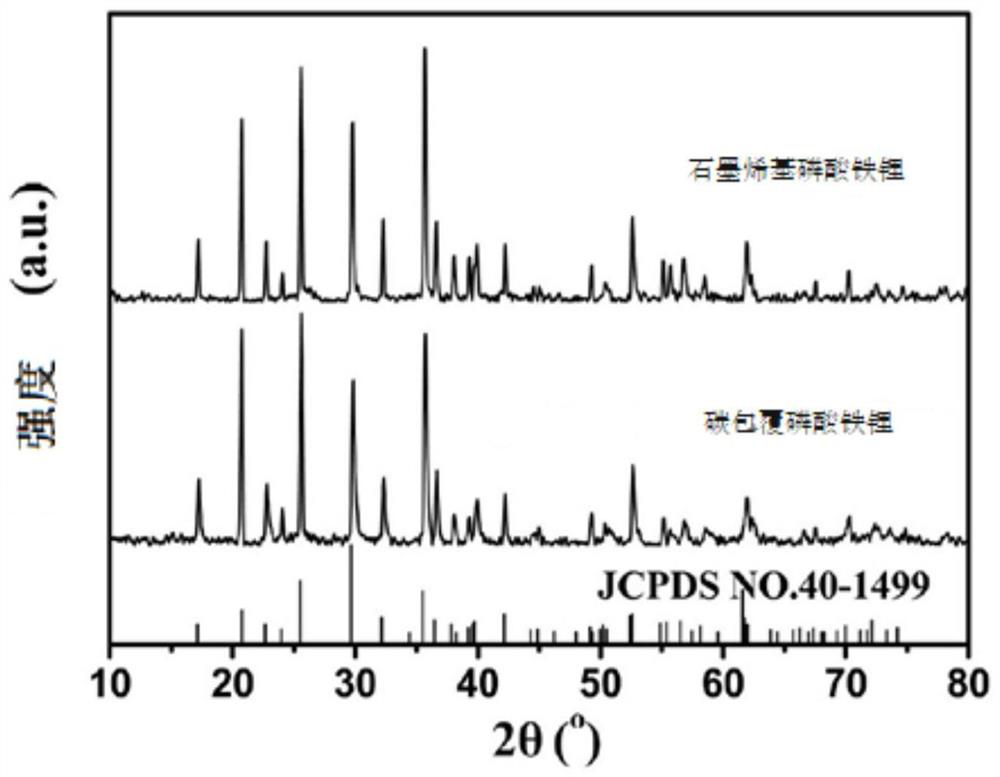

[0037] Mix the above composite material with lithium carbonate according to the molar ratio of Fe:Li of 1:1.01, add 10% glucose accounting for the mass of lithium iron phosphate, dis...

Embodiment 2

[0041] Weigh ferrous sulfate heptahydrate to dissolve and prepare a solution, then add graphene oxide slurry and stir evenly, the amount of graphene oxide added is 10% of the produced ferric phosphate quality, and the molar ratio of Fe:P is 1:1.1 before stirring Add ammonium hydrogen phosphate solution under low temperature, adjust the pH to 2.0-2.5 with ammonia water, then add surfactant OP-10, add hydrogen peroxide under stirring conditions, react and precipitate iron phosphate at 70-80°C, and remove the generated iron phosphate Washed with water, filtered, and vacuum-dried at 100°C, the dried sample was calcined at 500°C for 4 hours, cooled and ground to form a graphene oxide-iron phosphate composite material.

[0042] Mix the above-mentioned composite material with lithium carbonate according to the molar ratio of Fe:Li of 1:1.01, add glucose accounting for 7% of the mass of lithium iron phosphate, disperse in water at high speed, ball mill for 4 hours, take out the mixture...

Embodiment 3

[0044] Take the iron phosphate slurry before washing and mix it with the graphene oxide slurry. The amount of graphene oxide added is 2% of the mass of iron phosphate. The mixture is washed, filtered, and vacuum-dried at 100°C. Calcined for 4 hours, cooled and ground to form a graphene oxide-iron phosphate composite material.

[0045] Mix the above composite material with lithium carbonate according to the molar ratio of Fe:Li of 1:1.03, add 10% glucose accounting for the mass of lithium iron phosphate, disperse in water at high speed, ball mill for 4 hours, take out the mixture and dry it in vacuum at 100°C, and grind it to make precursor, and finally the precursor in N 2 In a reducing atmosphere, pre-sinter at 300°C for 4 hours, heat up to 700°C for 10 hours, and cool to room temperature with the furnace, then grind to obtain a graphene-based lithium iron phosphate cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com