Manufacturing method of ultrathin hot-rolled wide strip steel

A manufacturing method and technology for wide-band steel, which are applied in metal rolling, process efficiency improvement, furnace type, etc., can solve problems such as increasing production operation cost, deteriorating steel performance and quality, and breaking, and reduce processing costs and raw materials. Cost, effect of streamlining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

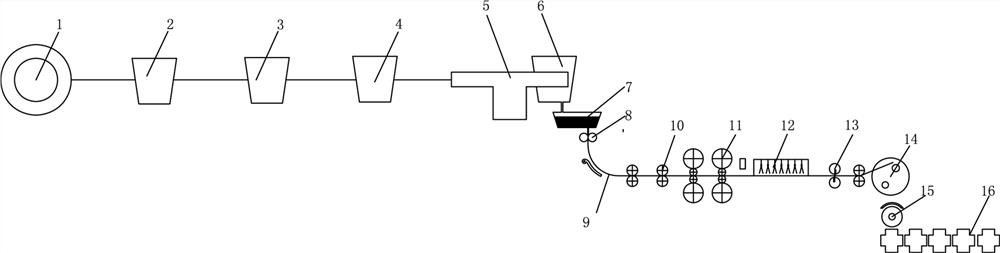

Method used

Image

Examples

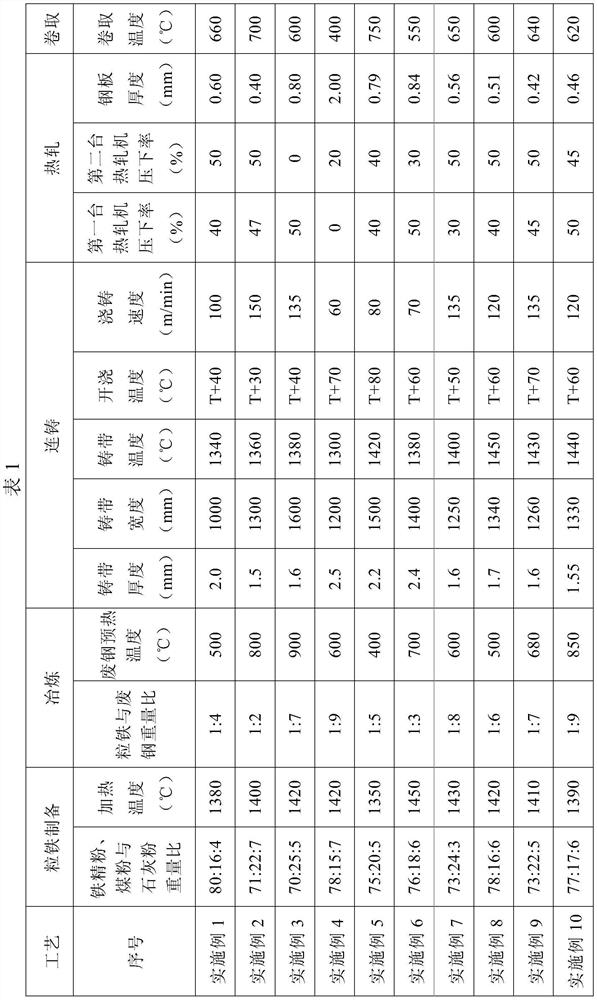

Embodiment 1

[0059] Mix the fine iron powder, coal powder and lime powder in proportion, press them into pellets or agglomerates and dry them; place them in the rotary hearth furnace 1, heat the rotary hearth furnace 1, and make the pellets in the rotary hearth furnace 1 Or the agglomerate is reduced, carburized, melted, and after rapid cooling, the granular iron and slag are separated and discharged separately; the heating temperature is 1380°C.

[0060] The granulated iron discharged from the rotary hearth furnace 1 is transported to the electric furnace 2, and the scrap steel preheated by the preheating device is mixed, melted and smelted in the electric furnace 2 for about 40 minutes, and then the steel is tapped. It is transported to the refining station for treatment. The molten steel is firstly decarburized, desulfurized and dehydrogenated in the VD vacuum degassing furnace 3, and then enters the LF refining furnace 4 for composition adjustment and temperature rise.

[0061] The ref...

Embodiment 2

[0065] Mix the fine iron powder, coal powder and lime powder in proportion, press them into pellets or agglomerates and dry them; place them in the rotary hearth furnace 1, heat the rotary hearth furnace 1, and make the pellets in the rotary hearth furnace 1 Or the agglomerate is reduced, carburized, melted, and after rapid cooling, the granular iron and slag are separated and discharged separately; the heating temperature is 1400°C.

[0066] The granulated iron discharged from the rotary hearth furnace 1 is transported to the electric furnace 2, mixed with the scrap steel preheated by the preheating device, and then melted and smelted in the electric furnace 2 for about 50 minutes. The ladle is transported to the refining station for treatment. The molten steel is first decarburized, desulfurized, and dehydrogenated in the VD vacuum degassing furnace 3, and then enters the LF refining furnace 4 for composition adjustment and temperature rise.

[0067]The refined molten steel ...

Embodiment 3

[0071] Mix the fine iron powder, coal powder and lime powder in proportion, press them into pellets or agglomerates and dry them; place them in the rotary hearth furnace 1, heat the rotary hearth furnace 1, and make the pellets in the rotary hearth furnace 1 Or the agglomerate is reduced, carburized, melted, and after rapid cooling, the granular iron and slag are separated and discharged separately; the heating temperature is 1420°C.

[0072] The granulated iron discharged from the rotary hearth furnace 1 is transported to the electric furnace 2, mixed with the scrap steel preheated by the preheating device, melted and smelted in the electric furnace for about 60 minutes, and then the steel is tapped. Transported to the refining station for treatment, the molten steel is first decarburized, desulfurized, and dehydrogenated in the VD vacuum degassing furnace 3, and then enters the LF refining furnace 4 for composition adjustment and temperature rise.

[0073] The refined molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com