High-temperature transparent flexible HfO2 anisotropic magnetic film and preparation method thereof

An anisotropic and magnetic thin film technology, applied in the field of functional materials, can solve the problems of limiting the practical application range of wearable magnetic sensor components, limiting the application range of HfO2 thin film materials, and the difficulty in obtaining large areas of natural single crystal mica. Wide range of bending radius of curvature, easy processing, enhanced magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Select the F-MICA substrate as a substrate, sequentially placed in a detergent, acetone, and ethanol in a substrate, and then rinse the substrate for a large amount of distilled water each time the ultrasonic wafer is washed with a large amount of distilled water.

[0032] Step 2: Put the clean F-MICA substrate in the ultraviolet light irradition for 40 min, so that the surface of the substrate reaches "atom cleanliness".

[0033] Step 3: CO (NO 3 ) 2 · 6h 2 O (cobalt nitrate), C 20 Hide 28 HFO 8 (Acetylacetonate) is proportional to the raw material, and the molar ratio of cobalt nitrate and acetylacetone is 0.1: 0.9. Cobalt nitrate and acetic acid were stirred for 15 min to mix the solution A, and the acetylacetonate and acetylacetone were mixed at 60 ° C water bath until dissolved to dissolve B. Finally, the solution A and solution B were mixed for 1.5 h, and 12 h was obtained from CO ion-doped HFO. 2 Pretty fluid.

[0034] Step 4: CO ion doped HFO 2 The precursor...

Embodiment 2

[0038] Step 1: Select the F-MICA substrate as a substrate, sequentially placed in a detergent, acetone, and ethanol in a substrate, and then rinse the substrate for a large amount of distilled water each time the ultrasonic wafer is washed with a large amount of distilled water.

[0039] Step 2: Put the clean F-MICA substrate in the ultraviolet light irradition for 40 min, so that the surface of the substrate reaches "atom cleanliness".

[0040] Step 3: CO (NO 3 ) 2 · 6h 2 O (cobalt nitrate), C 20 Hide 28 HFO 8 (Acetylacetonate) is proportional to the raw material, and the molar ratio of cobalt nitrate and acetylacetonate is 0.05: 0.95. Cobalt nitrate and acetic acid were stirred for 15 min to mix the solution A, and the acetylacetonate and acetylacetone were mixed at 60 ° C water bath until dissolved to dissolve B. Finally, the solution A and solution B were mixed for 1.5 h, and 12 h was obtained from CO ion-doped HFO. 2 Pretty fluid.

[0041] Step 4: CO ion doped HFO 2 The precu...

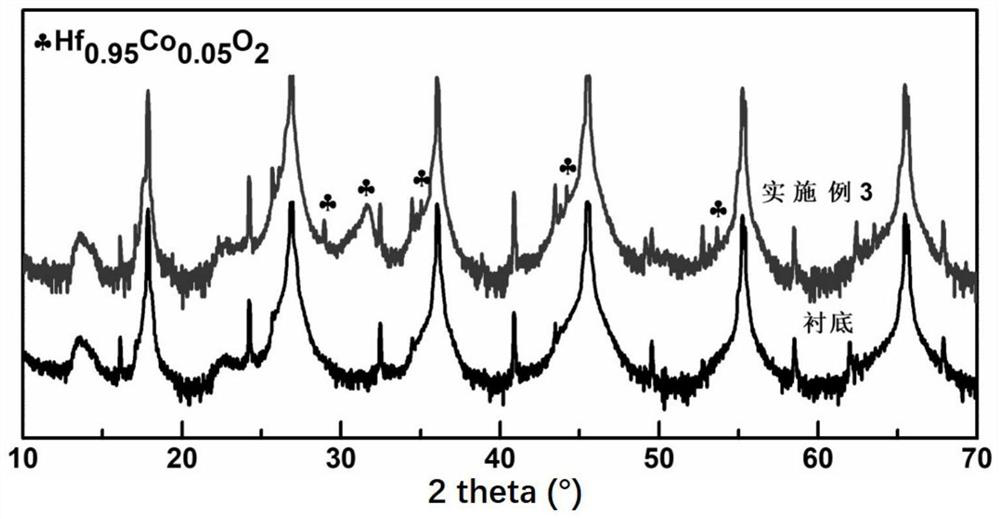

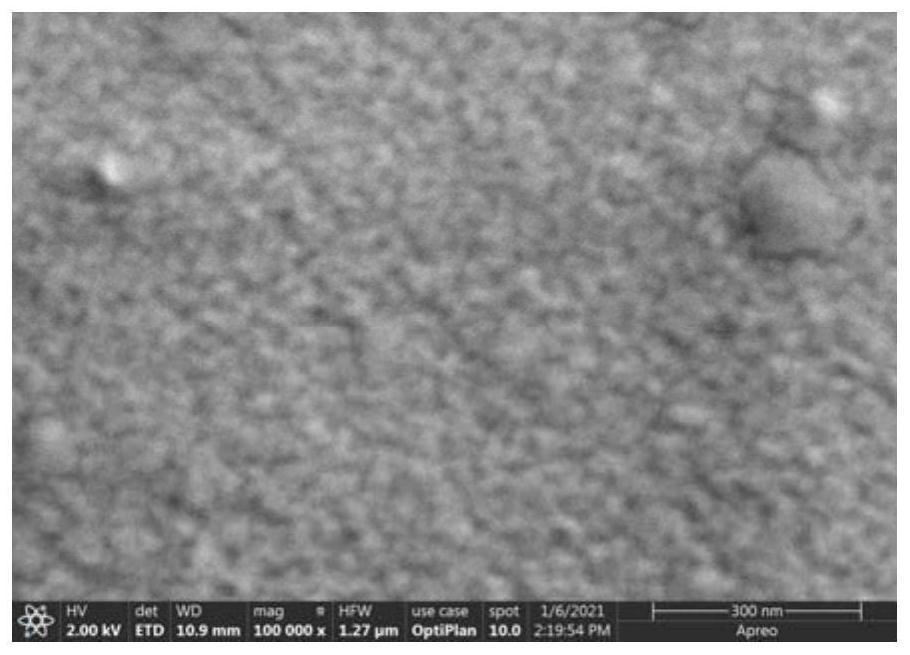

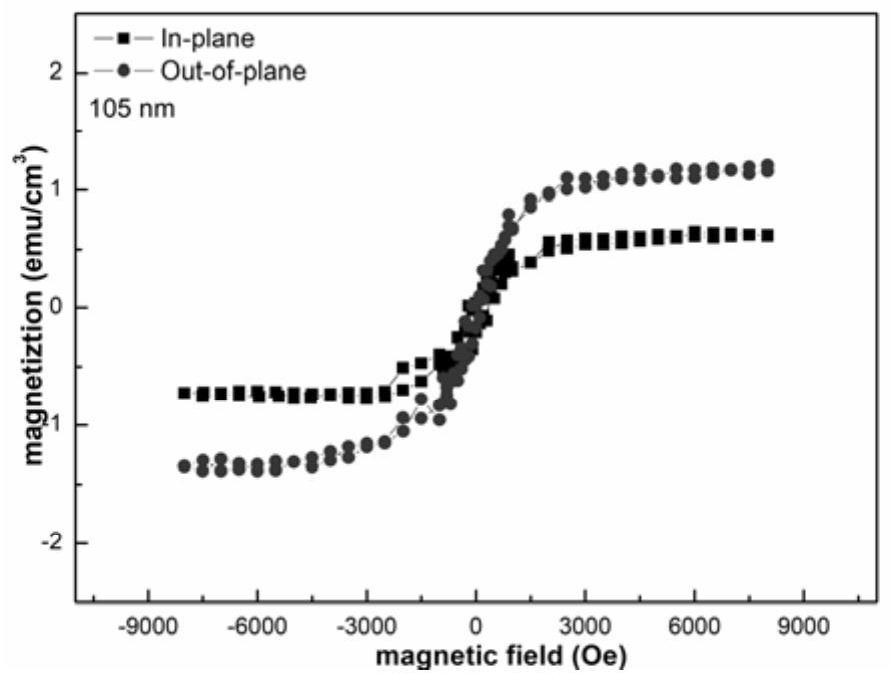

Embodiment 3

[0045] Step 1: Select the F-MICA substrate as a substrate, sequentially placed in a detergent, acetone, and ethanol in a substrate, and then rinse the substrate for a large amount of distilled water each time the ultrasonic wafer is washed with a large amount of distilled water.

[0046] Step 2: Put the clean F-MICA substrate in the ultraviolet light irradition for 40 min, so that the surface of the substrate reaches "atom cleanliness".

[0047] Step 3: CO (NO 3 ) 2 · 6h 2 O (cobalt nitrate), C 20 Hide 28 HFO 8 (Acetylacetonate) is proportional to the raw material, and the molar ratio of cobalt nitrate and acetylacetonate is 0.05: 0.95. Cobalt nitrate and acetic acid were stirred for 15 min to mix the solution A, and the acetylacetonate and acetylacetone were mixed at 60 ° C water bath until dissolved to dissolve B. Finally, two solutions were mixed for 1.5 h, and still 12 h got CO ion-doped HFO. 2 Pretty fluid.

[0048] Step 4: CO ion doped HFO 2 The precursor was prepared by a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com