Processing method of ion-doped gadolinium gallium garnet wafer

A technology of gadolinium gallium garnet and ion doping is applied in the field of precision machining of gadolinium gallium garnet wafers, and can solve the problems of less grinding and polishing processing, difficulty in ensuring flatness and surface quality, micro-deformation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

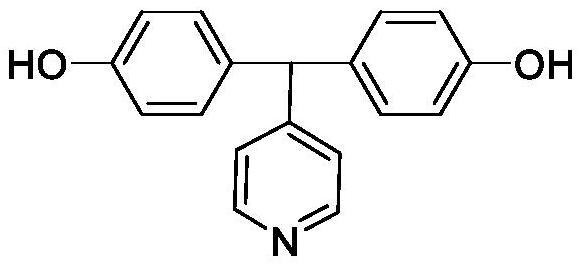

[0040] Preparation of additives:

[0041] A1. Mix 0.01mol of pyridine-4-carbaldehyde, 0.025mol of phenol and 1mL of glacial acetic acid evenly, and slowly add 25mL of a mixed solution of concentrated sulfuric acid and glacial acetic acid dropwise while stirring under an ice-water bath at 0°C. The dropping speed is 2 drops After the dropwise addition is complete, continue to react at 0°C and 200r / min for 48h, then pour 50mL of ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with 50mL of ice water until the filtrate is neutral. Then vacuum-dry the filter cake to constant weight to obtain phenol derivatives, wherein the mixed solution of concentrated sulfuric acid and glacial acetic acid is formed by mixing concentrated sulfuric acid and glacial acetic acid with a mass fraction of 98% according to a volume ratio of 1:4;

[0042] A2. Add 0.1mol pentaerythritol and 50mL glacial acetic acid into a three-necked flask equipped with a stirrer and ...

Embodiment 2

[0046] Preparation of additives:

[0047] A1. Mix 0.01mol of pyridine-4-carbaldehyde, 0.03mol of phenol and 20mL of glacial acetic acid evenly, and slowly add 35mL of a mixed solution of concentrated sulfuric acid and glacial acetic acid dropwise while stirring under an ice-water bath at 0°C. The dropping rate is 2 drops. After the dropwise addition is complete, continue to react at 0°C and 400r / min for 48h, then pour 50mL of ice water, stir for 50min, filter, take the filter cake and wash and filter repeatedly with 50mL of ice water until the filtrate is neutral. Then vacuum-dry the filter cake at 50°C to constant weight to obtain phenol derivatives, wherein the mixed solution of concentrated sulfuric acid and glacial acetic acid is formed by mixing concentrated sulfuric acid and glacial acetic acid with a mass fraction of 98% in a volume ratio of 1:4;

[0048] A2. Add 0.1mol pentaerythritol and 50mL glacial acetic acid into a three-necked flask equipped with a stirrer and a ...

Embodiment 3

[0052] Preparation of grinding liquid:

[0053] The grinding liquid is obtained by ultrasonic vibration of alumina (particle size: 4 μm) and deionized water for 20 minutes, and the concentration of alumina is 0.05 g / mL.

[0054] Preparation of mechanical polishing fluid:

[0055] The mechanical polishing solution was obtained by ultrasonically oscillating aluminum oxide (with a particle size of 1 μm) and deionized water for 20 minutes, and the concentration of aluminum oxide was 0.08 g / mL.

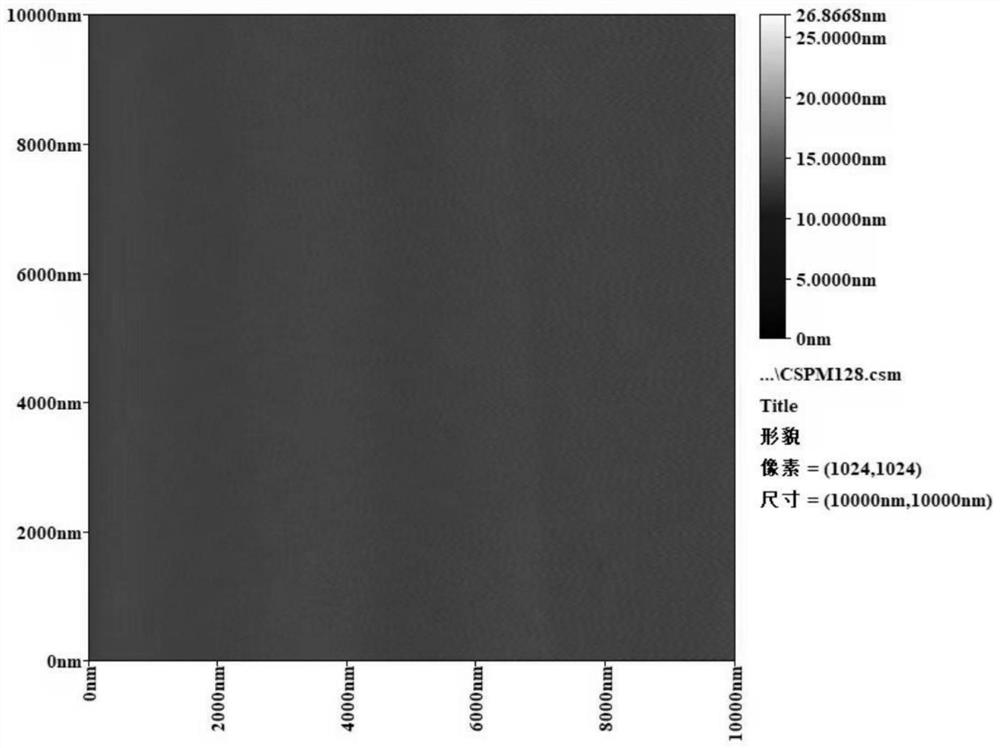

[0056] Preparation of silica sol polishing solution:

[0057] At room temperature, ultrasonically oscillate the silica sol, additives and deionized water for 15 minutes, then add abrasive cerium oxide and additives, continue ultrasonic oscillation for 30 minutes, and finally adjust the pH of the solution to 8 with citric acid to obtain a silica sol polishing solution , the mass ratio of silica sol, additives, deionized water, and cerium oxide is 10:1.5:95:5.5, and the particle size of ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com