Composite reverse osmosis membrane based on water-soluble polymer and preparation method thereof

A technology of water-soluble polymer and reverse osmosis membrane, which is applied in the direction of reverse osmosis, semi-permeable membrane separation, and general water supply saving, etc. The improvement is not significant, etc., to achieve the effect of increasing water flux, improving pollution resistance and permeability, and ensuring water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

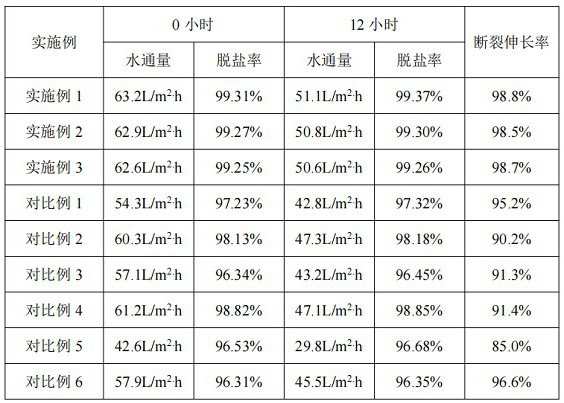

Examples

Embodiment 1

[0028] Step 1: (1) Mix 5 parts of m-phenylenediamine, 0.1 part of sodium dodecylbenzenesulfonate, 10 parts of thionyl chloride, 6 parts of glycerin, and 210 parts of deionized water to form a mixed solution, using 0.8wt% Camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=7.8 to obtain an aqueous phase solution; (2) Dissolving the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 24wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 2v / v% linoleic acid, set the temperature at 30°C and react for 4 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution and immerse for 1.5 minutes to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 2 minutes; place it in n-hexane extract solution for activation for 2 minutes; set the temperature to 80 ℃ drying for 5 minutes to obtain ...

Embodiment 2

[0031] Step 1: (1) Mix 4 parts of m-phenylenediamine, 0.08 parts of sodium dodecylbenzenesulfonate, 8 parts of thionyl chloride, 5 parts of glycerin, and 180 parts of deionized water to form a mixed solution, using 0.8wt% camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=7.2 to obtain an aqueous phase solution; (2) dissolve the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 20wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 1v / v% linoleic acid, set the temperature at 25°C and react for 2 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution and immerse for 1 minute to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 2 minutes; place it in n-hexane extract solution for activation for 1 minute; set the temperature to 75 ℃ drying for 5 minutes to obtain a pol...

Embodiment 3

[0034] Step 1: (1) Mix 6 parts of m-phenylenediamine, 0.12 parts of sodium dodecylbenzenesulfonate, 12 parts of thionyl chloride, 8 parts of glycerin, and 240 parts of deionized water to form a mixed solution, using 0.8wt% Camphorsulfonic acid solution, 0.5wt% sodium hydroxide solution to adjust pH=8.0 to obtain an aqueous phase solution; (2) Dissolving the trimesoyl chloride solution in the Isopa-G solution to obtain an oil phase solution with a concentration of 25wt% (3) Add the coated bacteria into n-hexane and mix evenly, add 3v / v% linoleic acid, set the temperature at 30°C and react for 4 hours; centrifuge to obtain n-hexane extract. (4) Place the polysulfone support membrane in the water phase solution for 2 minutes to remove excess water phase solution; transfer to the oil phase solution for interfacial polymerization for 3 minutes; place it in n-hexane extract solution for activation for 3 minutes; set the temperature to 82 ℃ drying for 8 minutes to obtain a polyamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com