A kind of conductive paste organic carrier and its preparation and application

A technology of organic carrier and conductive silver paste, which is applied in the field of composite material preparation, can solve the problems of toxic resistivity of volatile products, high sintering temperature of conductive silver paste, poor volatilization level, etc., to improve rheological properties, printing performance, and raw material price Inexpensive, the effect of changing the vapor pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The organic vehicle for the conductive paste of the present embodiment and its preparation and application are carried out as follows:

[0039] (1) Weigh 16g each of n-hexanol, diethylene glycol butyl ether acetate, and terpineol according to the mass ratio of 1:1:1, put them in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0040] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0041] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

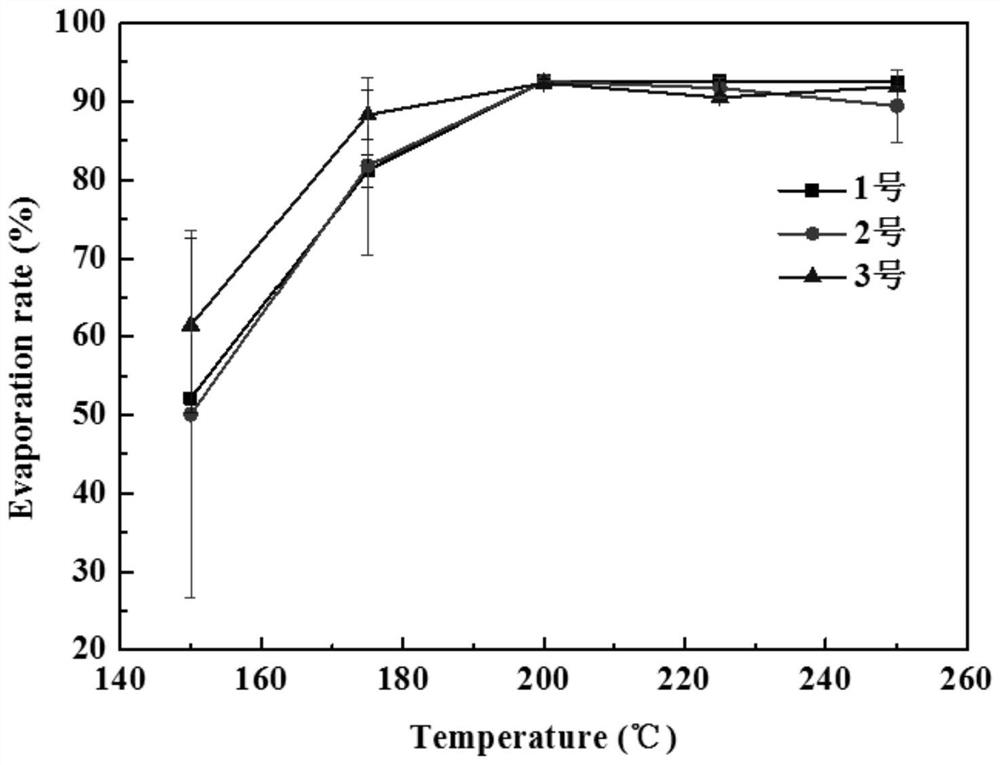

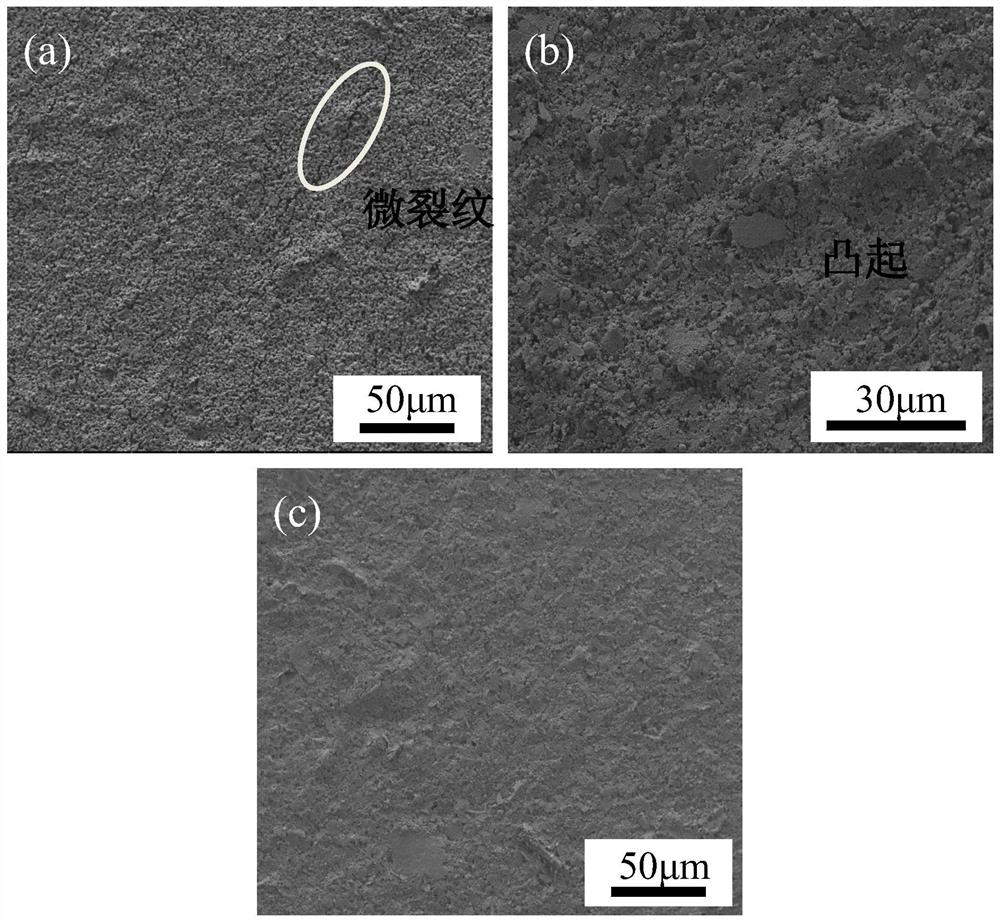

[0042](4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2 (the silver powder includes spherical silver powder with an average grain size of 1 μm and flake si...

Embodiment 2

[0045] The preparation method of the novel intermetallic compound based on high-entropy alloy diffusion welding in this embodiment is carried out in the following steps:

[0046] (1) Weigh 24g of n-hexanol and diethylene glycol butyl ether acetate according to the mass ratio of 1:1, put them in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0047] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0048] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

[0049] (4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2 (the silver powder includes spherical silver powder with an average grain size of 1 μm an...

Embodiment 3

[0052] The preparation method of the novel intermetallic compound based on high-entropy alloy diffusion welding in this embodiment is carried out in the following steps:

[0053] (1) Weigh 48g of n-hexanol, place it in a beaker and stir on a magnetic stirrer to make a uniform solvent.

[0054] (2) Weigh 3 g of polyvinylpyrrolidone (molecular weight: 1,300,000) and add it to the prepared solvent, place it on a magnetic stirrer and stir for 10 h until the PVP is completely dissolved in the solvent to obtain a viscous transparent liquid.

[0055] (3) Weigh 1g of castor oil and add it to the viscous liquid, place it on a magnetic stirrer until it is evenly stirred to obtain the required conductive paste organic vehicle.

[0056] (4) Mix the prepared organic carrier and silver powder according to the mass ratio of 1:2. The silver powder includes spherical silver powder with an average grain size of 1 μm and flake silver powder with a size of 1-5 μm and a thickness of 500 nm, and it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com